Lag-lead Design - University of Nevada, Reno

advertisement

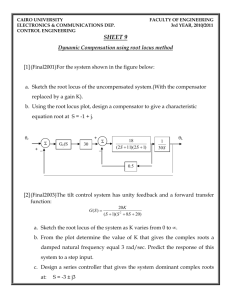

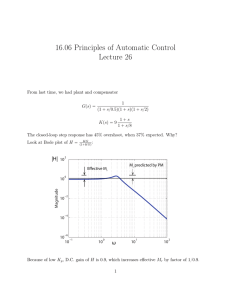

When is it needed? • Proportional control does not meet specifications (both transient response and steady-state error). • Lead meets transient response specifications. • Need a lag section to reduce the steadystate error. Lag-lead Design M. Sami Fadali Professor of Electrical Engineering University of Nevada, Reno 1 General form 2 Design Options 1. 1 • Lag-lead compensator 2. = 1 3 i. Select a suitable value for . ii. Design procedure (skip). 4 1. 1 Example • Design a lead compensator to improve the transient response . • Improve the steady-state response by adding a lag compensator. • Because the lag compensator will cause a deterioration in the transient response, it is advisable to use a somewhat conservative lead design. Design a lag-lead compensator for the system to obtain closed-loop dominant poles with a damping ratio of 0.5, an undamped natural frequency of 4 rad/s, and reduce the steady-state error by a factor of 5. 5 Solution : Lead Design 6 Solution From the lead presentation, we have : Lag Design Type 1: The lead section increases so we need by and the lead compensator 7 Check the time response and, if necessary, adjust the design to meet the specs. 8 2.i Step Response • Choose a value for =1/ sufficiently small to provide the desired specifications. System: Closed Loop r to y I/O: r to y Step Response Peak amplitude: 1.18 Overshoot (%): 17.6 At time (seconds): 0.719 1.4 1.2 • A m p litu d e 1 System: Closed Loop r to y I/O: r to y Settling time (seconds): 1.22 0.8 • Design a lead compensator with the selected . • For a conservative design, use = 0.1 and lead compensator angle 0.6 0.4 0.2 0 provides the necessary improvement in steady-state error. • For pole-zero cancellation (cancel pole at ) 0 0.2 0.4 0.6 0.8 1 Time (seconds) 1.2 1.4 1.6 1.8 2 9 2.i = 1 (Page 2) 10 Example • Add a lag section with = 1/. • Check the error constant and the pole locations for the design. • Check the time response and modify the design if necessary to meet the design specifications. • Compensator for pole-zero cancellation Design a lag-lead compensator for the system to obtain closed-loop dominant poles with a damping ratio of 0.5, an undamped natural of 4 rad/s, and reduce the frequency steady-state error by a factor of 3. Use the passive circuit subject to the constraint 11 12 Solution Solution (Page 2) Easier Design • Calculate the desired closed-loop pole location >> g=zpk([],[0,-2],4);scl=-2+j*2*sqrt(3) scl = -2.0000 + 3.4641i • The angle of the loop gain at the desired closedloop pole location is >> phi=pi-angle( evalfr(g,scl)) phi = 0.5236 Can use to calculate pole and zero locations. • Try = 0.2, = 5. Meets design specifications. • Cancel pole with zero: zero at 2 • Compensator pole at 2/ = 10 • MATLAB root locus plot: Gain =24.9 for • Lag Compensator: 13 MATLAB Commands Root Locus: Lead Compensation >> alpha=0.2; % alpha=1/beta Root Locus 10 9 Imaginary Axis (seconds-1) >> a=-real(scl)/10; System: untitled1 Gain: 24.9 Pole: -5 + 8.64i Damping: 0.501 Overshoot (%): 16.2 Frequency (rad/s): 9.98 8 7 6 14 >> gc=zpk(-2,-2/alpha,1)*zpk(-a,-alpha*a,24.6); Zero/pole/gain: 5 4 3 2 1 0 -1 -12 15 -10 -8 -6 -4 Real Axis (seconds-1) -2 0 2 24.6 (s+2) (s+0.5) ---------------(s+10) (s+0.1) 16 Compensated System 2.ii = 1: Design Procedure Adjust gain to improve the transient response: Reduce gain to 12 (compromise between settling and overshoot) System: Closed Loop r to y I/O: r to y Step Response Peak amplitude: 1.07 Overshoot (%): 7.09 At time (sec): 0.647 Amplitude 1.5 • Calculate the error constant for the system with proportional control and calculate the needed gain to meet the steady-state error requirements. • Obtain the ratio of the pole distance to the zero distance for the lead section using System: Closed Loop r to y I/O: r to y Settling Time (sec): 2.95 1 0.5 0 0 0.5 1 1.5 2 2.5 3 Time (sec) Pole-Zero Map Imaginary Axis 5 0 17 -5 -5 -4.5 -4 -3.5 -3 -2.5 -2 -1.5 -1 -0.5 18 0 Real Axis 2.ii = 1 Proc. (Page 2) 2.ii = 1 Proc. (Page 3) • Calculate the angle contribution of the lead section . • Obtain the pole and zero locations for the lead section using 1 cos( ) r 1 tan( z ) sin( ) z n d cos r 1 sin r cos( ) 1 tan( p ) sin( ) p n d r cos sin 19 • Add a lag section with where and are the pole and zero of the lead section. • Check the error constant and the pole locations for the design. • Check the time response and modify the design if necessary to meet the design specifications. 20