Introduction - 1000Bulbs.com

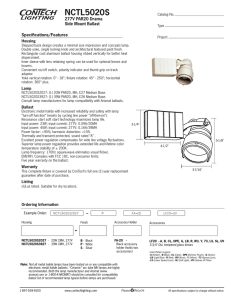

advertisement