Residential Transformer Loading Guidelines

advertisement

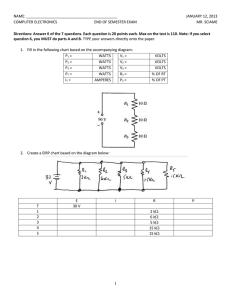

RESIDENTIAL TRANSFORMER LOADING GUIDELINES PEAK KW DEMAND REQUIREMENTS ON PEAK DAYS Electric Summer Electric Winter Gas Summer Gas Winter DIVERSITY TABLE ! %& %' " ( " ) ! %& %' # $ ) # ) ) ) ) ) " ( $ ) ) # " ) $) ) ) #) #) ) $ ) ) ) ) INITIAL AND MAXIMUM KVA LOADING SINGLE PHASE RESIDENTIAL OVERHEAD AND PAD MOUNTED TRANSFORMERS Transformer Size Summer 140% Winter 160% Transformer Size Summer 140% Winter 160% # # # # # NOTES: ( % %* # -. / % + %* , ( ( % ( ( , / // %( % % % %' % ' , " %* 2 % + / ( % %% ) 0% / ( % %% + '+ ) / / % +% % % + 1 0% %& % 0% + ( %( ( .// ' % ( . 3 % + / % % % % % + ( /%( /( % %% 3 ! "" " " " " " " " ! " ! " " " " " " ! ! " ! " ! ! ! " " ! ! # # # # # # #" #" # # # # # # # # #! #! # # # # # # # # #" #" # # # # # # # # #! #! # # "# $ "# 0 " 3 " $ !! ! " ! ! ! ! ! !! ! ! " "! "! " " % & ' ( ' & ) ) ! " ) ) & - . & * % + * + ), ) % ) )) $ $ ) ')/ ) % ) " 0 0 ' 1 / ' 1 ! + ( / ) ' * " " ! " " "" " " " " " " 2 $ "# 1 ! ! " ! # # # # # # #" #" # # # # # # # # #! #! # # # # # # # # #" #" # # # # # # # # #! #! # # "# $ "# 0 " ! " " ! " " " " " " " " ! " " "! !" ! ! " !! 2 3 $ "# 1 ! "! ! " # ! % ! $ ) & ) ' () % * % % "! ! ' # % " ! " " ! + " # #" , # ) ! ! , , " "" ( $ + - ) ). ) / ' % (. ( ) 1 --23 % 5 6! , 0 ! 0 ," 4 % 5 7 4 6, " !" ' ) :/ '23 % 5 6 "" # 7 8 $%"# 4 9 # & '()( 5 % 7 4 6, " !" # $%"# 7 8 # & '*) 9 Underground Residential Transformer Loading Guide Homes Between 700 and 1,200 Square Feet Number of Electric Number of Gas Customers Customers 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 0 0 25 25 25 25 25 25 25 50 50 50 50 50 50 50 50 50 100 100 100 100 1 25 25 25 25 25 25 50 50 50 50 50 50 50 50 100 100 100 100 100 100 2 25 25 25 25 50 50 50 50 50 50 50 50 100 100 100 100 100 100 100 3 25 25 25 50 50 50 50 50 50 50 50 100 100 100 100 100 100 100 4 25 50 50 50 50 50 50 50 50 100 100 100 100 100 100 100 100 5 50 50 50 50 50 50 50 100 100 100 100 100 100 100 100 100 6 50 50 50 50 50 100 100 100 100 100 100 100 100 100 100 7 50 50 50 100 100 100 100 100 100 100 100 100 100 100 8 50 50 100 100 100 100 100 100 100 100 100 100 100 9 100 100 100 100 100 100 100 100 100 100 100 100 10 100 100 100 100 100 100 100 100 100 100 100 11 100 100 100 100 100 100 100 100 100 100 12 100 100 100 100 100 100 100 100 100 13 100 100 100 100 100 100 100 100 14 100 100 100 100 100 100 100 15 100 100 100 100 100 167 16 100 100 100 167 167 17 167 167 167 167 18 167 167 167 19 167 167 20 167 Underground Residential Transformer Loading Guide Homes Between 1,200 and 1,500 Square Feet and Single Wide Mobile Homes Number of Electric Number of Gas Customers Customers 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 0 0 25 25 25 25 25 50 50 50 50 50 50 100 100 100 100 100 100 100 100 100 1 25 25 25 25 25 50 50 50 50 50 50 100 100 100 100 100 100 100 100 100 2 25 25 25 50 50 50 50 50 50 100 100 100 100 100 100 100 100 100 100 3 50 50 50 50 50 50 50 100 100 100 100 100 100 100 100 100 100 100 4 50 50 50 50 50 50 100 100 100 100 100 100 100 100 100 100 100 5 50 50 50 50 100 100 100 100 100 100 100 100 100 100 100 100 6 50 50 50 100 100 100 100 100 100 100 100 100 100 100 100 7 50 100 100 100 100 100 100 100 100 100 100 100 100 100 8 100 100 100 100 100 100 100 100 100 100 100 100 167 9 100 100 100 100 100 100 100 100 100 100 167 167 10 100 100 100 100 100 100 100 100 167 167 167 11 100 100 100 100 100 167 167 167 167 167 12 100 100 100 100 167 167 167 167 167 13 100 167 167 167 167 167 167 167 14 167 167 167 167 167 167 167 15 167 167 167 167 167 167 16 167 167 167 167 167 17 167 167 167 167 18 167 167 167 19 167 167 20 167 Underground Residential Transformer Loading Guide Homes Between 1,500 and 1,800 Square Feet Number of Electric Number of Gas Customers Customers 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 0 0 25 25 25 25 25 50 50 50 50 50 100 100 100 100 100 100 100 100 100 100 1 25 25 25 25 50 50 50 50 50 100 100 100 100 100 100 100 100 100 100 100 2 25 25 50 50 50 50 50 50 100 100 100 100 100 100 100 100 100 100 100 3 50 50 50 50 50 50 50 100 100 100 100 100 100 100 100 100 100 100 4 50 50 50 50 50 100 100 100 100 100 100 100 100 100 100 100 100 5 50 50 50 100 100 100 100 100 100 100 100 100 100 100 100 167 6 50 50 100 100 100 100 100 100 100 100 100 100 100 167 167 7 100 100 100 100 100 100 100 100 100 100 100 100 167 167 8 100 100 100 100 100 100 100 100 167 167 167 167 167 9 100 100 100 100 100 100 100 167 167 167 167 167 10 100 100 100 100 167 167 167 167 167 167 167 11 100 100 100 167 167 167 167 167 167 167 12 167 167 167 167 167 167 167 167 167 13 167 167 167 167 167 167 167 167 14 167 167 167 167 167 167 167 15 167 167 167 167 167 167 16 167 167 167 167 167 17 167 167 167 167 18 167 167 167 19 167 167 20 167 Underground Residential Transformer Loading Guide Homes Between 1,800 and 2,400 Square Feet Number of Electric Number of Gas Customers Customers 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 0 0 25 25 25 25 50 50 50 50 50 100 100 100 100 100 100 100 100 100 100 100 1 25 25 25 50 50 50 50 50 50 100 100 100 100 100 100 100 100 100 100 100 2 25 50 50 50 50 50 50 100 100 100 100 100 100 100 100 100 100 100 100 3 50 50 50 50 50 50 100 100 100 100 100 100 100 100 100 100 100 100 4 50 50 50 50 100 100 100 100 100 100 100 100 100 100 100 100 167 5 50 50 50 100 100 100 100 100 100 100 100 100 100 100 100 167 6 50 100 100 100 100 100 100 100 100 100 100 100 100 167 167 7 100 100 100 100 100 100 100 100 100 100 167 167 167 167 8 100 100 100 100 100 100 100 100 167 167 167 167 167 9 100 100 100 100 100 167 167 167 167 167 167 167 10 100 100 100 100 167 167 167 167 167 167 167 11 100 167 167 167 167 167 167 167 167 167 12 167 167 167 167 167 167 167 167 167 13 167 167 167 167 167 167 167 167 14 167 167 167 167 167 167 167 15 167 167 167 167 167 167 16 167 167 167 167 167 17 167 167 167 167 18 167 167 167 19 167 167 20 167 Underground Residential Transformer Loading Guide Homes Between 2,400 and 3,000 Square Feet Number of Electric Number of Gas Customers Customers 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 0 0 25 25 25 25 50 50 50 50 100 100 100 100 100 100 100 100 100 100 167 167 1 25 25 25 50 50 50 50 100 100 100 100 100 100 100 100 100 100 100 167 167 2 25 50 50 50 50 50 100 100 100 100 100 100 100 100 100 167 167 167 167 3 50 50 50 50 100 100 100 100 100 100 100 100 100 100 167 167 167 167 4 50 50 50 100 100 100 100 100 100 100 100 100 167 167 167 167 167 5 100 100 100 100 100 100 100 100 100 100 100 167 167 167 167 167 6 100 100 100 100 100 100 100 100 167 167 167 167 167 167 167 7 100 100 100 100 100 100 167 167 167 167 167 167 167 167 8 100 100 100 167 167 167 167 167 167 167 167 167 167 9 167 167 167 167 167 167 167 167 167 167 167 167 10 167 167 167 167 167 167 167 167 167 167 167 11 167 167 167 167 167 167 167 167 167 167 12 167 167 167 167 167 167 167 167 167 13 167 167 167 167 167 167 14 167 167 Demand Factors 1. General The following definitions: a. Demand The value of electrical power required for a particular load. Generally stated as maximum demand required and is expressed in kW. The maximum demand is usually the integrated maximum demand over a 15 or 30-minute interval rather than the instantaneous or peak demand. b. Demand Factor The ratio of the maximum demand on a system to the total connected load of the system. c. Diversity Factor The ratio of the maximum demand of the whole system to the total of the individual maximum demands of the components of the system. Diversity factor is always less than unity. 2. Published Demand Factors Motors (general purpose - machine tool ventilation, compressors, pumps, rolling mills, etc.) 30% Motors (semi-continuous operations - paper mills, refineries, rubber mills) 60% Motors (continuous operations - textile mills) 90% Electric ovens, heaters, furnaces 80% Induction furnaces 80% Arc furnaces 100% Arc welders 30% Resistance welders 20% 3. Typical Demand Factors a. Refrigeration and A/C (1) Package (0-10 tons) (2) Package (10 -25 tons) (3) Package (25-50 tons) (4) Package (50-100 tons) (5) Package (100 and up) (6) Centrifugal (200 tons & up) (7) Centrifugal (all auxiliaries) 1.6 kW / ton 1.4 kW / ton 1.2 kW / ton 1.1 kW / ton 1.0 kW / ton 0.6 - 0.9 kW / ton (compressor only) 0.7 - 0.8 (connected kW) b. Textile (1) Cotton Mills (2) Synthetics (3) Knitting 0.6 (connected HP) 0.5 (connected HP) 0.5 (connected HP) c. Furniture d. Metalworking (1) Heavy Manufacturing (2) Light Manufacturing 0.4 - 0.45 (connected HP) 0.2 - 0.3 (connected HP) e. Sawmills 0.3 - 0.4 (connected HP) f. Arc Welders 0.2 - 0.3 (nameplate kVA or kW) g. Spot Welders 0.1 - 0.15 (nameplate kVA or kW) h. Lighting 1.0 I. Resistance Heat (1) Environmental (2) Process j. Asphalt Plant 0.45 (connected HP) 0.4 - 1.0 0.4 - 0.6 0.8 k. Rock Quarry 0.4 - 0.6 l. 1.0 Electric Melting m. Air Compressor 0.3 - 0.8 Estimating Customer Demand Factors Background To begin this section, one should have a basic understanding of metering and know the difference between kW and kWh. One should also be able to calculate the kW from HP, Tons, BTUh, and Amps and Volts. Demand Estimation Demand is defined as the rate of energy consumption during a specific time period. Many utilities use 60-minutes, 30-minutes, or 15-minutes. Some utilities may use a rolling 5-minute interval. Why should we be concerned with this interval maximum rate? This interval maximum determines the size of a utilities generation facilities, distribution systems, and the transformer size at the customer’s location. Let us think about our own personal residence for a moment. Let’s list the electrical loads in our home. Range Electric Heater Air Conditioner Television Refrigerator Water Heater Lights Hair Dryer Toaster Dishwasher Microwave Washing Machine Clothes Dryer 8,000 watts 8,000 watts 4,000 watts 700 watts 750 watts 4,500 watts 2,500 watts 1,500 watts 750 watts 2,000 watts 1,000 watts 250 watts 5,000 watts Total Connected Load 38,950 watts If all of these loads in our home stayed on all month, our personal electric bills would be almost $2,000 per month. No one could afford to build electric generation facilities to meet this type of demand. Obviously, all of these loads do not operate at the same time, therefore, these loads have “diversity”. The heating and air conditioning in the home do not operate simultaneously, the television is not always on, we do not wash clothes twenty-four hours a day. These are the elements which go into making up load diversity. The maximum demand on your house will probably never exceed 12 kW. Therefore, the diversity factor for your home would be 12 kW / 38.95 kW = 0.31 or 31% diversity. Knowing how loads interact and being able to figure their contribution to the maximum demand is essential for sizing contracts. How does one develop a reasonable demand estimate of a customer? Do we let the customer or the consulting engineer tell us (the utility) what his demand level is going to be? Not usually. This is normally the worst method of deriving a maximum demand. The typical consulting engineering is not concerned with how much the utility has to spend to provide service, he is concerned with insuring the service is more than adequate to serve a particular load. However, the customer, the consulting engineer, or both are the best sources to get us started. They can provide the best insight into the type of load, the size of the load, the time and season in which the load operates. All of this information plus good common sense will start one down the road to estimating the demand level. Now that we have the benefit of the information the customer has provided us, let’s separate the load into two basic groups. These are base loads and weather responsive loads. These two groups are broad groups into which all loads can be divided. The base load group covers all loads used without respect to weather conditions. Some load types in this group are lighting, motors, food service, water heating, receptacle load, and business machines. The second broad group is composed of whether responsive loads which are heating and air conditioning. This group is of great concern to the utility since their peak will usually occur on the hottest day or coldest day of the year and the utility must have sufficient generation, distribution facilities, and transformers even for that short period of time. Base loads and whether responsive are two broad groups into which we must first divide our loads. Once this is done, a closer look at each element within these groups can be made. Lighting (interior) is considered a base load and is essential in all types of business. Lighting has a very high diversity factor, usually in the range of 85 to 90 percent. It will seldom be 100 percent because someone will always be out of the office, burned out lamps will not be replaced, or lamps in closets will not be on. Lighting (exterior) is not usually considered in calculating maximum interval demand levels. This is due to the fact that this light usually is on only at night when other demands are low. The exception to every rule is a ballpark or tennis court which is usually the only load or biggest load on the delivery. Water Heating is considered a base load and has a wide of range of diversity. Water heating load associated with restrooms in office buildings could reflect in the range of 0 to 5 percent. However, water heating associated with food service or laundries could have a diversity of 10 to 40 percent. In some instances the diversity could be as high as 100 percent. Food Service load is considered a base load and is one of the more difficult to predict in its effect on demand. This type of load could range from a small kitchen unit in an office building to a professional bake shop. To give one a range in which to begin for commercial heavy used kitchens, the range of diversified load should fall between 25 and 40 percent. Receptacles are considered base load and should be diversified from 0 to no more than 10 percent. This type load includes typewriters, computers, desk lamps, coffee pots, calculators, radios, and other receptacle load. Space Heating, whether provided by heat pumps, resistance, or radiant heat, are considered weather responsive loads. These heaters are usually controlled by some type of thermostat which controls how often and how long these units will run. In most North Carolina service areas, the design temperature is between 10oF and 25oF, which means if a unit is properly sized it will not run all of the time until the outside temperature reaches 10oF to 25oF. However, heating units are usually oversized, and people, lights, and other loads give off heat; therefore, the full capacity of installed units is rarely on all the time. Space heating and interior lighting directly complement each other. If the total heat loss of the structure is 8 watts per square foot and 10 watts of heat per square foot has been installed, plus an additional 2½ watts per square foot of interior lighting, and both heat and lights are on, it is obvious that the thermostats will be satisfied on the heating system before the full 10 watts per square foot of heat is reflected on the meter, unless a possible combination of cold start-up and severe weather exists. Air Conditioning is another weather responsive load. It is very important to keep seasonal loads separate. Therefore, it will be necessary to calculate both summer demand level and a winter demand level to determine which is greater. If air conditioning is installed, it is usually designed to maintain 75oF to 78oF inside when the temperature outside is 95oF. On most buildings, one will need to use 100 percent diversity unless drastic over sizing is noted. Air conditioning and interior lighting directly “buck” or “fight” each other. This is the opposite effect of combined heating and lighting. Other Loads could be either weather responsive or base load depending upon the use of the load. Examples of other loads that one will find in buildings are as follows: Elevators Service elevators are used to move people at peak periods. Therefore, a diversity of 0 to 25 percent could be used. (Usually 0 percent in large buildings.) Computers Are these small computers that are or machines used by the entire company 24 hours per day? Motors They can be used to move either air or products. They can be used 24 hours per day or one hour a week. These and other loads are all going to have to be identified by you and a judgement made on their contribution to a peak demand. If assistance is required, one should search out good advice from other sources. This is merely the first step in demand estimation. Once a summer and winter peak has been established, one should use every method available to assure the proper contract demand. This means using other methods of demand estimation to check the calculation. One of these methods is a watts per square foot method. One simply takes the watts per square foot historically used by the same type of structure and multiples the watts per square foot times the square footage of the structure in question. The kW demand one obtains with the watts per square foot method should closely correspond to the diversification you perform. If this is not true, one should investigate the diversity factors that were used. A second method used to check the diversification of loads is the percent of connected load method. With this method, one must first sum all of the loads for each season. Then, take the percent of reflected load historically used by the same type of structure, multiplied by the connected load. Here again, if the projected kW demand is not close to the diversified method, one should investigate. The last, and probably the best method of checking your projected demand is the comparable building method. This is used when you know that the builder is using a standard set of plans which are used with only minor modifications for all of their company’s stores; much like Family Dollar Stores, Wal-Mart Stores, and others. With this type of structure, one should find the billing history on a store similar to the one being built and see what the demand levels have been running. Future Load - The contract is normally set for the anticipated demand level to be reached during the original term of the contract. Often, the customer will indicate that growth is anticipated beyond this original term, and another decision has to be made; whether to install a transformer ample for present day loads or suitable for future conditions. Each delivery should be judged in its respect on its own set of conditions; such as the customer’s financial position, historical development trends, state of the economy, etc. This should enable one to accurately project demand and speak to customers intelligently on high bill complaints. However, remember the two biggest tools in estimating demand levels are good information and good common sense. Actual Watts per Square Foot Averages & % Connected Load Averages Watts / Foot2 % Connected Load Winter a Summer Winter Summer b Banks 9.2 6.3 41% 53% Offices 7.7 6.4 32% 53% Churches 9.7 6.2 43% 59% Convenience Stores 13.0 12.7 45% 93% Department Stores 6.9 5.6 46% 82% Medical Clinics 11.3 8.6 44% 69% Grocery Stores 10.1 10.4 45% 61% Restaurants (Fast Food) 45.8 41.5 37% 39% Restaurants (Family) 27.3 21.9 44% 52% Variety Stores 10.2 7.1 51% 81% Schools 10.2 5.6 43% 48% Motels 7.6 4.6 34% 52% a - Structures with electric space heating b - Less connected heat kW The number of samples used to obtain these figures is not large enough to be considered absolute - use as general guidelines only. Range of Watts per Square Foot Averages & % Connected Load Averages Watts / Foot2 % Connected Load Winter a Summer Winter Summer b Banks 7 - 11 4-8 35 - 45% 50 - 60% Offices 6 - 10 5.5 - 7.5 25 - 40% 40 - 60% Churches 8 - 11 4.5 - 7.5 40 - 50% 55 - 65% Convenience Stores 11 - 15 10.5 - 14.5 40 - 50% 88 - 98% Department Stores 6 - 7.5 4.5 - 6 35 - 55% 70 - 90% Industrial (Process) 6 - 12 6 - 12 40 - 65% 40 - 65% Medical Clinics 8 - 14 6.5 - 10.5 35 - 55% 60 - 80% Grocery Stores 9 - 12 9 - 12 35 - 55% 50 - 70% Restaurants (Fast Food) 30 - 60 30 - 60 35 - 50% 30 - 50% Restaurants (Family) 17 - 37 16 - 30 35 - 55% 40 - 60% Variety Stores 8 - 12.5 5.5 - 9 40 - 60% 75 - 95% Schools 10 - 12 5-7 35 - 55% 40 - 60% Motels 5 - 11 3.5 - 5.5 30 - 40% 50 - 70% a - Structures with electric space heating b - Less connected heat kW The number of samples used to obtain these figures is not large enough to be considered absolute - use as general guidelines only. GUIDELINES FOR DETERMINING WHETHER A COMMERCIAL CUSTOMER’S EXPECTED DEMAND WOULD BE GREATER OR LESS THAN 15 KW To help you determine whether a customer’s expected demand would be greater than 15 kW, first obtain from the customer the conditioned square footage of the location involved. (Conditioned square footage is the area of the building that is either heated or cooled.) Then multiply the watts per square foot (as listed below for different types of businesses) by the conditioned square footage of the location to determine the approximate load in watts. Divide by 1000 to convert this figure to kilowatts. Remember that if the customer has electric heat, use the amount in the “Winter” column. If the does not heat electrically, use the amount in the “Summer” column (based on air conditioning load). If the customer does not have electric heat or air conditioning, this chart is not applicable. Watts / Foot2 Winter Summer Banks 9.2 6.3 Offices 7.7 6.4 Churches 9.7 6.2 Convenience Stores 13.0 12.7 Department Stores 6.9 5.6 Medical Clinics 11.3 8.6 Grocery Stores 10.1 10.4 Restaurants (Fast Food) 45.8 41.5 Restaurants (Family) 27.3 21.9 Variety Stores 10.2 7.1 Schools 10.2 5.6 Motels 7.6 4.6 Note: Most small auxiliary accounts such as workshops, well pumps, etc., would have a kW demand of less than 15 kW. The number of samples used to obtain the figures listed above is not large enough to be considered absolute. It should be used as a general guideline only. MOTOR DATA HP AVERAGE EFFICIENCY, % KW 1/20 40 0.09 1/12 49 0.12 1/8 55 0.17 1/6 60 0.21 ¼ 65 0.29 1/3 66 0.37 ½ 65 0.57 3/4 72 0.78 1 79 0.94 1½ 79 1.42 2 79 1.89 3 84 2.66 5 84 4.44 7½ 85 6.58 10 87 8.57 15 87 12.86 20 87 17.15 25 87 21.44 30 89 25.15 40 89 33.53 50 89 41.91 60 90 49.73 75 91 61.48 100 91 81.98 125 91 102.47 150 91 122.97 200 91 163.96 INPUT POWER OF PACKAGE A/C AND REFRIGERATION UNITS TONNAGE TOTAL SYSTEM INPUT INCLUDING AUXILIARIES PACKAGE UNITS 0 - 10 TONS 1.6 KW / TON PACKAGE UNITS 11 - 25 TONS 1.4 KW / TON PACKAGE UNITS 26 - 50 TONS 1.2 KW / TON PACKAGE UNITS 51 - 100 TONS 1.1 KW / TON PACKAGE UNITS 101 TONS & UP 1.0 KW / TON CENTRIFUGAL 1.0 KW / TON Multiply the number of tons times the number of kW per ton. For Example: 1. 2. 3. 2 tons: 11 tons: 27 tons: 2 tons x 1.6 kW / ton = 3.2 kW 11 tons x 1.4 kW / ton = 15.4 kW 27 tons x 1.2 kW / ton = 32.4 kW BTU’S PER HOUR AND TONS CONVERSION BTU’S PER HOUR TONS 12,000 1 18,000 1½ 24,000 2 30,000 2½ 36,000 3 42,000 3½ 48,000 4 54,000 4½ 60,000 5 AVERAGE RANGE OF DIVERSITY FACTORS FOR SERVICE LOCATIONS Lighting (exterior) 0% Lighting (interior) 85% - 90% Base Load 0% - 10% Water Heating: Domestic Sanitary 0% - 10% 10% - 40% Food Service: Small Facility Regular Restaurant Fast Food 0% - 10% 25% - 40% 50% - 60% Heating 8 watts / square foot minus lighting load or 100% Cooling Motors: Process 100% Commercial Industrial 25% - 30% 10% - 65% 30% - 65% LUMENS PER WATT FOR HID SOURCES WITH AND WITHOUT BALLAST LOSSES AND AT 70% OF LIFE A B C D E F G H With Ballast Losses Total Lamp Type Lamp Wattage Initial Lumens LDD @ 70% of Life Lumens @ 70% of Life Wattage with Ballast LPW Initial LPW @ 70% of Life Life (Hours) 1 Mercury DX 100 4,200 0.63 2,646 127 42.0 20.8 24,000 + 2 Mercury DX 175 8,600 0.78 6,708 205 49.1 32.7 24,000 + 3 Mercury DX 250 12,100 0.74 8,954 290 41.7 30.9 24,000 + 4 Mercury DX 400 22,500 0.71 15,975 450 50.0 35.5 24,000 + 5 Mercury DX 1000 63,000 0.52 32,760 1070 58.0 30.6 24,000 + 6 Metal Halide 175 14,000 0.72 10,080 210 66.7 48.0 7,500 7 Metal Halide 250 20,500 0.71 14,555 300 68.3 48.5 10,000 8 Metal Halide 400 34,000 0.70 23,800 455 74.7 52.3 20,000A 9 Metal Halide (Super) 400 40,000 0.70 28,000 455 87.9 61.5 15,000 10 Metal Halide 1000 110,000 0.73 80,300 1075 102.3 74.7 12,000 11 Metal Halide (Super) 1000 125,000 0.73 91,250 1075 116.3 84.9 12,000 12 High Pressure Sodium 70 5,800 0.83 4,814 88 65.9 54.7 24,000 + 13 High Pressure Sodium 100 9,500 0.83 7,885 130 73.1 60.7 24,000 + 14 High Pressure Sodium 150 16,000 0.83 13,280 188 85.1 70.6 24,000 + 15 High Pressure Sodium 250 27,500 0.83 22,825 300 91.7 76.1 24,000 + 16 High Pressure Sodium 400 50,000 0.83 41,500 465 107.5 89.3 24,000 + 17 High Pressure Sodium 1000 140,000 0.77 107,800 1100 127.3 98.0 24,000 + A - 20,000 hours if operated 15% of vertical, otherwise 15,000 hours COMPARISON OF PERFORMANCE FOR INCANDESCENT VS. LOW WATTAGE FLUORESCENT AND HID SOURCES A B C D E F G H With Ballast Losses Total Lamp Wattage Initial Lumens LDD @ 70% of Life Lumens @ 70% of Life Wattage with Ballast LPW Initial LPW @ 70% of Life Life (Hours) 22 870 0.70 609 22 39.6 27.7 16,000 44 1,750 0.70 1,225 44 39.8 27.8 7,500 161 850 0.70 595 16 53 37.2 7,500 441 1,750 0.70 1,225 44 39.8 27.8 7,500 Twin Tube Fluorescent 7 400 0.68 272 12* 33.3 22.6 10,000 (PL Lamps) 9 600 0.70 420 12 50.0 35.0 10,000 13 900 0.70 630 17 52.9 37.1 10,000 35 2,250 0.83 1,868 45 50.0 41.5 24,000 + 50 4,000 0.83 3,320 63 63.5 52.7 24,000 + 70 5,800 0.83 4,814 87 66.7 55.3 24,000 + 60 870 0.86 748 60 14.5 12.5 1,000 A-19 ES 67 1,130 0.86 972 67 16.9 14.5 750 A-19 75 1,190 0.86 1,023 75 15.9 13.6 750 A-19 100 1,750 0.86 1,505 100 17.5 15.0 750 A-21 150 2,850 0.86 2,451 150 19.0 16.3 750 A-23 200 4,010 0.86 3,449 200 20.1 17.2 750 Lamp Type Circlite HPS (Clear) Incandescent2 A-19 3 1 - 2-Way Lamp (16-44W) 2 - Incandescent Lamps are Inside Frosted 3 - Energy Saving Incandescent * - With Multi-tap ballast Note: Circlite, Twin Tube Fluorescent, and HPS lamps are usually lower power factor (30-60%). This should be considered in equipment sizing.