CaSA News - the ISPE Carolina

advertisement

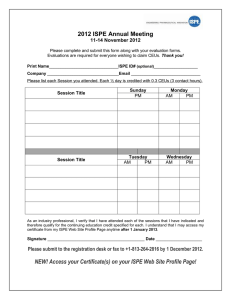

Connecting a World of Pharmaceutical Knowledge Carolina-South Atlantic Chapter Volume 22 • Number 6 President’s Message Greetings ISPE CaSA Chapter! As 2015 comes to an end, it’s the perfect time to reflect on the past years’ accomplishments for our Chapter. Looking back, we have had many inspiring moments! Thanks to the hard work and dedication of our Board of Directors and Committee members, the CaSA Chapter hosted two Education events in Atlanta. Lisa Kerner Plans are in the works for more events in Atlanta, and a new reach into the Tampa market. This is a huge accomplishment for our Chapter and it is exciting to see our growth throughout the Southeast!! RTP happenings remain solid! The 2015-16 Annual Planning Session…a.k.a. “Oktoberfest” had record-breaking attendance with 150 attendees. Oktoberfest was designed to re-engage current members and motivate new industry friends to get involved and join ISPE. The Networking Committee did an amazing job organizing the event. This is just the beginning of what’s to come in 2016! The ISPE Annual Meeting was held November 8-11 in Philadelphia with over 1800 industry professionals and students in attendance. The CaSA Chapter was well represented by our membership, as well as our Student Chapters. Each year, the Chapter sponsors a group of Student Chapter representatives to attend the Annual Meeting. This year, we proudly sponsored 12 students from North Carolina State University, North Carolina Central University, East Carolina University and Campbell University. These 12 students have been dedicated to serving their University Chapters. Engaging the future generations of leaders is a key initiative for CaSA and the value our Chapter brings to the industry. Looking ahead to 2016, I am honored to be working with such a strong Board of Directors and Committees who have embraced my vision to re-engage our members, recharge our events and grow the CaSA Chapter by hosting great education and networking events! Meaningful education events show the value that ISPE brings to our membership and the Life Sciences industry. And, we like to have fun too! So, don’t forget about the networking opportunities the Chapter has to offer!! Of course, the Chapter’s successes would not be possible without you! We hope that you will join us at our upcoming events! Keep an eye on your email for registration and sponsorship opportunities. See next page for a list of what’s coming up. See you soon!! Lisa Kerner President, ISPE CaSA Chapter Re-Engage. Recharge. Grow. CaSA News Featured Sponsors December 2015 4242 Switchbox Position Indicator • Class 1 Div 2 • Groups C & D • High visibility • Mechanical • Override • 24 VDC, AS-I, • DeviceNet For more details contact: dcannon@gemu.com www.gemu.com 3800 Camp Creek Parkway Building 2600 • Suite 120 Atlanta, Georgia 30331 Tel: 678-553-3400 Fax: 404-344-9350 2 January 28, 2016 RTP Therapeutic Thursday at Blackfinn Ameripub Morrisville, NC INSIDE THIS ISSUE President’s Message.................................................................1 2015-2016 Board of Directors..................................................2 February 27, 2016 Gala at the North Carolina Museum of Art Raleigh, NC Education Committee...............................................................3 CaSA Committees.....................................................................3 Networking Committee............................................................4 March 31, 2016 23rd Annual Technology Conference Raleigh, NC Welcome New CaSA Members.................................................5 Member Spotlight....................................................................6 Student Affairs..........................................................................7 April 2016 ATL and RTP Education Events Technology Conference............................................................7 May 16, 2016 22nd Annual Golf Tournament at Prestonwood Country Club Cary, NC Board of Directors Officers Lisa Kerner, President Bruce Craven, Vice President Wendy Haines, Treasurer Mike Putnam, Secretary Heather Denny, Past President Technology Corner....................................................................9 2015 Advertising and Sponsorship Opportunities..................13 Electronic Media.....................................................................14 2015-2016 Directors Andy Ferrell Chip Chappell Wes Robbins Committee Chairs Marisol Patino, Student Affairs Jim Hubbard, Education Justin Rothwell, IT/Social Media Eric Mayer, Networking Terence Morrison, Membership Development Jamie Sigmon, Young Professionals Amy Lineberry, Technology Conference Rich Stanfield, Newsletter TrackSense Pro Sky Solution Real Time Data • • • • • Lyophilization Sterilization Depyrogenation Mapping Applications Interchangeable sensors For an in-depth demo contact | P. Roy Snipes Regional Sales manager | rs@ellab.com | 919.414.9812 Carolina-South Atlantic Chapter 3 Membership Corner Education Committee By Jim Hubbard, Education Committee January 11, 2016 - Education Committee’s “Call for Partners” (most spots were filled in 72 hours this year) March 31, 2016 - Education sessions at the 2016 Tech Conference in Raleigh April 13, 2016 - Education/Networking event in Atlanta (new market) April 14, 2016 - Education/Networking event in Raleigh June 23, 2016 - Education/Networking event in Tampa, FL (new market) CaSA COMMITTEES How can you participate in growing Education in our industry? • Attend an event! • Submit an abstract for the Tech Conference. • Become an Education partner (there are many benefits for your company). • Volunteer as a member of the committee. • Volunteer as a SME to speak at events. • Offer suggestions for ideas or improvements. Please call me to discuss how you can get involved in your local ISPE-CaSA Chapter. Jim Hubbard, Education Chair, 240-344-1109 √ 2015-2016 Student Affairs Marisol Patino Young Professionals Jamie Sigmon Networking Eric Mayer Technology Conference Amy Lineberry IT/Social Media Justin Rothwell Education Jim Hubbard Membership Development Terence Morrison Newsletter Rich Stanfield ıķłĿĺķŊĿŅń ĞŅŃŃĿʼnʼnĿŅńĿńĽ ĜŋŊŅŃķŊĿŅńĠńĽĿńĻĻňĿńĽ ĬŋķłĿŊŏīňŅĽňķŃʼn ĮŅļŊōķňĻĨķńķĽĻŃĻńŊ ĭĻŃĻĺĿķŊĿŅń ħķĸŅňķŊŅňŏĤįĞŅŃņłĿķńĹĻ ĮŋņņłŏĞľķĿńĬŋķłĿŊŏ ĭĻŃŅŊĻĨŅńĿŊŅňĿńĽ īňŅĹĻʼnʼnĪņŊĿŃĿŐķŊĿŅń ōōōʼnĻŇŋĻńĹĻŇĹʼnĹŅŃ)ĿńļŅ"ʼnĻŇŋĻńĹĻŇĹʼnĹŅŃ) ĢķŊĻōķŏĞĻńŊňĻĝłŌĺĮŋĿŊĻĨŅňňĿʼnŌĿłłĻĩĞ Leadership. Compliance. Reliability. Calibration and maintenance services from startup to operations to shutdown. • Process systems • Laboratory systems • Building utilities • Full asset management 877-724-2257 • www.pci-llc.com 4 Membership Corner Networking Committee By Eric V. Mayer, Networking Committee Thanks to all the ISPE-CaSA team for supporting Oktoberfest 2016! We had 18 great sponsors to insure the event was a huge success. Thanks so much CRB, CAI, Watson-Marlow, PCI, Hipp, STI, EMD, PEG, RGD, Avid, Bray, EHS, IPS, Hydro, FLW Southeast, Statesville Process, Mettler Toledo, and Steris. NNE Pharmaplan put on a great Therapeutic Thursday on 19 November at the Carolina Ale House. Save the date of 16 May for the ISPE-CaSA Golf Tournament at Prestonwood Country Club. Sponsorship opportunities will be published soon. See below, upcoming networking events. √ Boost your knowledge. Expand your network. Date Event Sponsored By ISPE’s and Chapters are your resource for all things ISPE—from 28 JanAffiliatesTherapeutic Thursday in local Raleigh ClarkNexsen translations of ISPE’s world-renowned Guidance Documents to education on regional industry trends. 28 Jan and regulatory Therapeutic Thursday in Atlanta TBD 25 involved Feb Therapeutic Thursday in or Raleigh Commissioning Get with your regional Affiliate Chapter to meet industry leaders inAgents your area, contribute your expertise to industry-advancing initiatives at the local level and share best practices with like-minded professionals. Connecting a World of Pharmaceutical Knowledge Get Involved With Your Affiliate or Chapter Today! ISPE.org/Affiliates-and-Chapters www.ISPE.org/Affiliates-and-Chapters Bring it on. R mcdonaldyork.com | 919.832.3770 PHARMACEUTICAL/ BIOTECHNOLOGY PROJECT SPECIALISTS ■ ■ ■ ■ ■ Project Planning/Design Process & Facility Design Scheduling/Cost Estimating Construction Support On-Site Resources AARON SINK 919.755.1033 www.hipp-usa.com Double Bonus When You Join ISPE By12.31.15! (See next page for more details) 5 Membership Corner $40 DISCOUNT NOW AVAILABLE FOR NEW INDUSTRY MEMBERSHIPS! By Terence Morrison, P.E., CAP, LEED AP BD+C, ISA 84 SFS, Membership Development Committee $40 DISCOUNT NOW AVAILABLE FOR NEW INDUSTRY MEMBERSHIPS! Applications can be made online at www.ispe.org/join, click on “Join Now” under Industry Membership, and enter CASA2015 in the promotion code box. Please remember ISPE’s Refer-A-Friend Program! Earn one free month of membership for every friend you refer. All the details are available at: http://www.ispe.org/membership-referral-program ISPE wants YOU! That’s why we have put together a custom-tailored offer that delivers ISPE’s full benefit package to increase your knowledge, confidence and skill, together with 2 additional benefits that make joining an incredible value: Technology Transfer (2nd Edition) – ISPE Good Practice Guide This easy-to-read, user-friendly resource will guide you step by step through each phase of the process from planning and development to final monitoring and improvement. Charts and diagrams visually reinforce key points and a series of appendices provide actual examples of technology transfer deployed in real-world settings. pharmaceutical lifecycle, chances are ISPE’s conferences cover topics that meet your needs. Use this discount certificate and save big $$$ on 4 of the industry’s most significant events. If you have any question about ISPE or the CaSA Chapter, please contact me at membership@ispecasa.org. $250 Conference Discount Certificate From aseptic processing technologies, to meeting with regulators, to a showcase of the latest solutions for the Welcome New Members Industry US$269/£219 New Members who joined October 9, 2015 through December 9, 2015 Kevin David Watkins Larry Yudell Leallyn T. Murtagh Thomas Garrett Meshaw Beth Smullen Neil Corman Jon Grutchfield Kelly Principi Maegan Leigh Smith Miss Jordyn C. Weaver Arinc Leishear Dereze Juwan Kinsler Pusp Bhatt Ashley I. Bowen Ciara N. Williams Deshanae Meaders Mariah Y. Richards Shante Lunsford Tydasia Felton David Lauer Kahlil DeRoche Delineliz Zayas Flavia Hoffmann Robin Kumoluyi Ananda Ghimire Chiagozie Agbai Eliran Nunez Allison Lewis Brittany L. Carson Joanna M. Cheek LaPrince Miller-Smith Maryah E. Wright Mia B. Hall Nada Abuzaid Nathalie Unico Rommy Guevara Mary Beth Pugh Ken Jones Dawit Sima Jessica Faulkner Kaci Kennedy Porsha Thompson Shaunetta Campbell Ashley Stanley Erik Kopache Shahid Ali Nafees Deanna Dahir Carl B. Richardson Chandi Carter Tammy Strickland Sam Dilks Christian Estes Ricardo Rafael Lopez Daniel Santarsiero Courtenay Knox Frank Holley, Jr., Exe.VP Kevin Hotter Emily Pait Jinxiang Zhou Grant Dietrich Jesse Faber Tobin Weiseman Tommy Thorn, Jr. Laurene Fitzgerald Bryan Raborn Dionna J. Nobles Join Now Casey Holbrook Greg Ahrens Heather J. Stefan Kathleen Naylon Michael Prazma Christine Knul Bindu Battineni Hershel Meadows Randy Woodard Michael Contino Sarah Gabrielle Dillard Dr. Sandra M. Davern Hafsa Khanom William Earl Boyd Josh Hutson Bruce Benson Ann Doscher Keith Kulowiec 6 Membership Corner 7 CaSA Member Spotlight: Mariessa Rose-Lorraine Blunt Q: What is your full name? A: Mariessa Rose-Lorraine Blunt . Q: Birth Place? A: Tucson, Arizona. Q: College? A: Campbell University, Buies Creek, North Carolina for both B.S. and M.S. in Pharmaceutical Sciences. Q: What is your present position? What do you do at your job? A: Campbell University, Buies Creek, North Carolina for both B.S. and M.S. in Pharmaceutical Sciences. Q: Tell me a little about your personal life. A: I was born and raised in Southern Arizona and have only been in North Carolina for almost 3 years. I have a 6 year old Cockapoo dog named Daisy and 3 Siberian cats named R2D2, Skywalker, and Jar Jar Binks. I am a frequent concert goer and big Star Wars fan. Q: What is your present position? What do you do at your job? A: I am currently a second-year graduate student in the Masters of Science in Pharmaceutical Sciences program. My studies primarily focus on biotechnology/bioprocessing and pharmacology. I am the current ISPE Campbell University Student Chapter President. Q: How long have you been with your current employer? A: This is my third year at Campbell University. Q: Tell me how you ended up where you are today. A: I initially wanted to be a mathematician but since moving to North Carolina I have discovered a passion for the pharmaceutical industry and the role pharmaceutical scientists play in healthcare. I would like to pursue a career in upstream process development. Q: What is your favorite part of your job? A: My favorite part about being a student is the opportunities I have had to hold various officer’s positions in the ISPE Campbell University Student Chapter. I truly enjoy being able to lead our Student Chapter to various community events and raise awareness of the pharmaceutical sciences. Q: How long have you been a member of ISPE/when did you first join ISPE? A: I joined the ISPE Campbell University Student Chapter in the beginning of 2014. I have since been the 2014-2015 secretary and the current President of our Chapter. Q: What benefits have you realized from being a member of ISPE? A: The most important benefit I have gained from being a member in ISPE is being able to network with people from all aspects of the pharmaceutical industry that I normally would not have been able to interact with. Also, being an active member of my Student Chapter has helped me build my leadership and organizational skills. Q: Why are you still involved with ISPE? A: ISPE provides multiple opportunities to network and continue my education on current topics and trends that are happening in industry. It is also enjoyable to be around like-minded, goal oriented people. Q: Any Mentors/Role Models that have helped to shape your life? A:I have met many great and kind people while being involved with ISPE; however, Dr. Daniel Shin, Jamie Sigmon, and Dr. Wendy Haines have been generous with their time and have given advice that has been invaluable to me. Q: If you weren’t involved in pharma/ biotech, what business do you think you’d be in? A: I have a strong passion for the arts and helping people, so I could see myself doing Art Therapy with children. Q: What is one skill you wish you had that you don’t? A: I wish I had better cooking skills. Q: Any hobbies? What are they? A: I have many hobbies that all revolve around creating art. I love getting lost in any sort of art project, whether it is oil painting, graphite sketching or sculpting. Q: Do you collect anything? A: I collect Star Wars memorabilia. Q: Finish this sentence – “I need more….” A: I need more laughter in my day. Sometimes, I often get caught up in the stresses of upcoming exams, planning events, or my research project. I need to remind myself more frequently to stop and smile for a moment. Q: Favorite Food? A: My favorite food is sushi. Q: What is something that people would be surprised to learn about you? A: Despite being born and raised in Arizona, I have never been to the Grand Canyon. Q: Last movie you saw? A: Jurassic World Q: For those in the early stage of their careers, what advice would you give them? A: I would say start networking as soon as possible. Even if you are unsure of what you would like to do in the industry, get yourself out there and take every opportunity you can to learn and grow. √ Student Affairs 7 Membership Corner By Marisol Patiño, Student Affairs Committee This month several of our ISPE student members attended the 2015 Annual Meeting. We had a large group attend with about 14 students representing 4 university student chapters. Students were able to get a better understanding of all the roles within the pharmaceutical industry: “The annual meeting really broadened my knowledge about the career paths available after graduation. Our department at school really encourages us to go into manufacturing, but our students aren’t limited to that. They can just as easily go into something like consulting or validation or supplying.” They were inspired by the educational sessions: “The Office of Manufacturing Quality talk made me more interested in FDA policies and regulations. This talk revealed a huge gap in my knowledge, and I got an idea about having an acronym list for students, readily downloadable during the talk.” “Interacting with people at the exhibit was my favorite activity. Whether it was asking about what they look for in their new recruits or asking them about their instruments and understanding the variety of latest technology used in Pharmaceutical sciences.” They learned how to expand their network: "I bought a GoPro and took selfies with everyone I saw to help break the ice. I was open about how it was my first ISPE Annual meeting and the professionals were so willing to open up and educate. “After the conference, I feel more confidence about talking with industrial professionals and networking.” Some of the highlights for the students included a bowling social with other students and young professionals, meeting the local CaSA chapter executive board, and meeting John Bournas, CEO of ISPE globally (they got a selfie with him!). Next, the students will be encouraged to begin working on posters to enter the poster competition in March at the ISPE-CaSA Technology Conference. The winners earn an all-expenses paid trip to the 2016 Annual Meeting in Atlanta and a chance to compete nationally. √ Technology Conference 2016 Is Right Around the Corner By Amy Lineberry, CPIP, Technology Conference Committee We are happy to announce exhibitor registration opened on December 8, 2015 for the 23rd Annual ISPE-CaSA Life Sciences Technology Conference. Be sure to visit www.ispe-casa.org/2016 to reserve your table or booth today, as they are sure to sell fast! Be sure to keep an eye on your email for more announcements about the Technology Conference. This should be the best conference yet, with more tables and great education sessions. We are also working to secure a great Keynote with more information about new things happening in the CaSA region. Attendee registration will open in January. We hope to see everyone on March 31, 2016 at the Raleigh Convention Center. Exhibitor Registration NOW OPEN!!! √ 9 Technology Corner The cycle development approach By Kevin Debbs Senior Pharmaceutical Specialist – CRB described in this document is fairly universal and should not be dependent on individual isolator systems. The terminology used may be slightly different depending on the technology, but the general principles, process descriptions, and process and execution steps can still be applied across various isolator systems. PURPOSE The purpose of this white paper is to provide a High-Level overview and road map to plan and execute of the following aspects of H2O2 decontamination cycle development. • A process overview of the Vapor Hydrogen Peroxide (H2O2) decontamination cycle. • The planning and pre-requisite activities that must be completed prior to the execution of the H2O2 decontamination cycle development. • Execution of the H2O2 decontamination cycle development. • Performance Qualification (PQ) of the H2O2 decontamination cycle development. H2O2 DECONTAMINATION CYCLE PHASES The typical decontamination cycle consists of four separate and distinct phases: Pre- Conditioning, Conditioning, Decontamination and Aeration. 1. Pre-Conditioning a. The initial physical conditions of temperature, humidity and air velocity inside the isolator are established. Additionally, the vaporizing plates are heated to a set-point temperature and the liquid H2O2 is delivered to the vaporizing plates. Typically the control system of the isolator will determine if a sufficient amount of liquid H2O2 is available to complete the decontamination cycle. H2O2 is not injected into the isolator during this phase. This phase only establishes the proper 2. 3. 4. a. condition to successfully and repeatedly execute the H2O2 decontamination. Conditioning a. During the conditioning phase, vapor phase hydrogen peroxide is introduced into the isolator chamber and prepares the isolator environment for the desired decontamination effect. Decontamination a. Decontamination is the process step where the desired de contamination effect is achieved. Aeration Aeration is the final process step that removes the residual H2O2 from the Isolator to a specified set point. Figure 1 1. 2. 3. 4. Preconditioning Conditioning Decontamination Aeration 10 H2O2 DECONTAMINATION CYCLE DEVELOPMENT PREREQUISITES Prior to initiating cycle development, there are items that should be completed. Each of these items will affect the cycle development for the H2O2 cycle. As testing is completed and compiled, keep in mind that the end goal is to have an effective and efficient H2O2 cycle. 1. Execute FAT a. Factory acceptance testing should be completed prior to executing H2O2 cycle development. A popular approach recently is to perform as much of the installation verification (IV) and functional testing as possible during the Factory Acceptance Test (FAT) and then leverage all this testing going forward. This leveraged approach enables testing to begin early in the Commissioning/ Qualification/ Validation (CQV) process that can help to save time on the overall project schedule and save significant money. Testing is only executed once and is referenced or leveraged in subsequent CQV documentation. This also provides early confidence the system was fabricated and assembled in accordance with the design documentation and functions as intended. Problems that are identified during the FAT can be fixed in the vendor’s shop prior to shipment. 2. Perform Airflow Pattern Testing a. Airflow pattern testing to visualize the airflow patterns inside the isolator should be performed during the FAT and then repeated after installation once the isolator is installed on the filler. This testing can be used to select the worst case positions. 3. Perform High Efficiency Particulate Air (HEPA) Filter Certification a. The upstream side of the filters is challenged with an Emory 3004 aerosol and then the filter faces are scanned with photometers to determine overall leakage. 4. Loop Checks and Calibration of Instruments for Critical Process Parameters a. Prior to or during the FAT, instrument loop checks should be performed for all digital and analog inputs and outputs. This will provide evidence that the instruments are wired correctly, the proper signals being exchanged and displayed on the HMI and the instruments are measuring within the proven acceptable range. b. Instruments that measure and monitor critical process parameters must be calibrated to ensure the instruments are accurate and precise within proven acceptable ranges, thereby allowing the H2O2 decontamination process to be properly characterized and defined. 5. Determine the Isolator Load Pattern a. Isolator Load Pattern should be defined with the worst case load of items inside the isolator to challenge the decontamination cycle. The items loaded into the isolator will affect the airflow, the decontamination time, and the duration of aeration. b. The exact quantity and location of each items needs to be defined and documented so the load pattern can be consistently repeated without variation which would then help to ensure that the decontamination cycle can be successfully re-qualified without deviations. 6. Perform Manual Cleaning a. The internal surfaces of the isolator including the inside and outside of each glove, the filler and the ancillary equipment should be thoroughly cleaned manually with 70% IPA or an approved cleaning solution. The H2O2 decontamination process is a surface decontamination process and will not penetrate into cracks, crevices and other occluded surfaces if the isolator is not properly cleaned. Therefore, the H2O2 de contamination process is only as good as the cleaning process. b. This initial cleaning could be combined with a bio- burden reduction study to evaluate the bioburden post cleaning. 7. Qualify the Room Environment a. The background room environment must be commissioned and qualified to provide a controlled and stable environment with respect to differential pressure control, temperature and humidity, so the isolator and the decontamination cycle can be qualified. b. The Environmental Monitoring Performance Qualification (EMPQ) does not necessarily need to be completed prior to executing cycle development. 8. Determine the Process Sequencing a. Cleaning and Cooling i. The cool zone sterilization of the depyrogenation tunnel (if applicable), the CIP / SIP of the filling equipment and the H2O2 decontamination cycle should be sequenced in such a way to avoid hot surfaces during the decontamination cycle. Hot surfaces present a worst case situation to achieve the desired killing effect and should be avoided during the decontamination cycle. Optimizing the sequence of operations can reduce the overall cycle time between lots / batches. ii. The optimal way to sequence these activities is to initiate a cool zone sterilization of the dry heat tunnel (if applicable) and a CIP cycle concurrently. These two activities can also be sequenced in series (one after the other) if cycle time is not important. iii. Once the surfaces inside the isolator that were exposed to elevated temperature cool to < 40°C, the H2O2 the decontamination cycle can be initiated. iv. When the decontamination cycle progresses to the aeration phase and is approximately < 10ppm, the SIP cycle can be initiated. Otherwise the SIP can be started once the aeration phase is complete and the residual H2O2 acceptance criteria levels have been achieved. Starting the SIP of the filling loop during aeration is a way to shave some time off of the entire cycle time if aeration is a long process. 9. Glove Integrity Testing a. Both physical and visual glove integrity testing should be performed prior to each H2O2 decontamination cycle. Physical tests usually involve one of three methods: a flow test, a pres sure decay test or a trace gas sensing method to detect leaks. Each physical test method has their advantages and disadvantages; therefore, each method must be properly evaluated. Visual inspection should also be paired with physical testing to check for gross defects. Furthermore, visual inspection of isolator gloves should be performed during each isolator intervention. b. Following the glove integrity testing, glove extenders or 11 glove holders should be used to extend the gloves inside the isolator to eliminate folds and creases that prevent the gloves and sleeves from being fully exposed to H2O2. Depending on the isolator design, it may be necessary to extend the isolator glove on the outside of the isolator to execute the glove integrity testing on select gloves. In this situation, a negative pressure chamber can be used to extend the gloves outside the isolator. c. Glove integrity testing and insertion of the glove extenders or glove holders are typically the last pre- requisite operation performed in the isolator prior to initiating the H2O2 deconta mination cycle. 10.Determine the Biological Indicator (BI) vendor and qualify the lot of BIs. a. The BI vendor and the individual lots of BIs must be qualified prior to cycle development to understand the BI performance with respect to D-value. Too often cycle development is executed without knowing the D-value of the BI and how it performs within a specific isolator with a specific process. b. The BI also needs to be evaluated for identification and population. c. The gold standard BI for H2O2 Decontamination Cycle Development is Geobacillus stearothermophilus with a population of 1 x 106 spores per carrier on a stainless steel coupon as represented by ATCC 12980 from Apex Labs. H2O2 CYCLE DEVELOPMENT EXECUTION The cycle development of the H2O2 bio-decontamination can be executed in a progressive manner. BI qualification and Chemical and temperature mapping must occur prior to developing a worst case study. 1. BI Qualification a. D-value: The resistance of a BI against a defined inactivation method is expressed by decimal reduction per unit of time (min). b. The D-value describes the time unit it takes to reduce the test organism population 90%. c. Conduct a series of D-values studies to understand the re sponse of the BI (relative resistance and behavior) and the killing effect of the corresponding cycle development parameters that created the conditions in the target isolator environment by use of a Fractional-Negative method. d. The D-value studies are executed by exposing pre- deter mined groups of BIs with multiple BIs per group to H2O2 vapor. e. At pre-defined intervals, each group of BIs are removed from the isolator environment and evaluated using a growth promotion test. f. The goal of the fractional negative method is to achieve a total-kill of the test organism via growth tests and then deter mine the D-value and survival/kill window. g. The D-values studies are executed in a location inside the isolator that will provide the best exposure conditions to the vaporized H2O2. This will generally be a location immediately below the HEPA filter where the H2O2 vapor is being generated or being injected. There should also be no airflow obstructions above or around the BIs used in these studies. h. The calculation of the D-value mean is the average of three D-value evaluations plus a 25% safety factor. i. Use the D-value mean to design the length of the decontamination portion of the decontamination cycle. 2. Temperature, Humidity and Chemical Indicator (CI) Mapping a. Thermocouples and / or temperature and humidity sensors are used to map the temperature and humidity conditions on various surfaces inside the isolator. b. High temperature and low humidity would be indicative of a worst case location for the killing effect of H2O2. c. These locations should be included and challenged with BIs as part of the cycle development worst case study. d. A chemical indicator is used to demonstrate H2O2 distribution within the isolator system. e. The chemical Indicator challenge can be executed as an in dependent test or executed in conjunction with temperature and humidity mapping. If the chemical indicator challenge is executed independently, the CIs with the worst color change should be included and challenged with the BIs in those locations as part of the cycle development worst case study. 3. Worst Case Biological Indicator (BI) Study a. The worst case study is accomplished by first selecting the challenge locations inside the isolator. These challenge locations should be selected based on the results of the preceding tests that were executed as well as some geometric locations. b. The worst case study is executed with three (3) BIs per location. The worst case study can easily have between 100 – 150 BI Challenge locations depending on the size and complexity of the filling and isolator systems. Finally, it is critical that Engineering and C&Q are aligned with the Quality group on the identification and selection of the worst case locations. This agreement should be formalized by having Quality review and approve the H2O2 Cycle Development protocol. c. Locations to be considered / selected and included in the worst case study: i. The worst case airflow pattern locations can be locations where there is not turbulent flow or locations that are under equipment, devices, instruments, motors, conveyors, under windows, corners, etc. Direct observation and / or video analysis of the airflow patterns will allow you to easily visualize the problem areas that may present challenges to achieve the desired decontamination effect. ii. The temperature and humidity mapping locations that demonstrated elevated temperatures and lower humidity should be included in the worst case study. These temperature and humidity locations may present more difficulty in achieving the desired killing effect. iii. The chemical indicator mapping locations that had the worst color change should be included in the worst case study. iv. Occluded Surfaces are all hard to reach locations where the airflow of the isolator system may have trouble delivering the vaporized hydrogen peroxide to achieve the desired killing effect. v. Critical Zones are areas within the filling and isolator systems where there is manipulation of product contact parts including isolator gloves and sleeves. Additional locations should be selected to properly challenge the isolator system to consistently and effectively achieve the desired decontamination effect. vi. The E-Beam tunnel (if present) is typically part of the sur face area that is decontaminated with the isolator system. The E-Beam should be included in all of the appropriate testing to 12 evaluate the system during H2O2 cycle development. vii. Entrances and Exits to the isolator system need to be i ncluded in the worst case location study to properly evaluate the isolator system. This should include all transfer locations such as Rapid Transfer Ports (RTPs), transfer isolator locations and piping connections. viii. BIs should also be placed on gloves and sleeves. Typically, BIs are placed in two general positions: The first on the sleeve in the most challenging position as the gloves are extended into the isolator and secondly on the fingers of the gloves. To determine the final sleeve position(s), each glove extender length needs to be determined, fixed and consistently replicated for each decontamination cycle. ix. Consult the quality group to see if there are locations inside the isolator they want to see challenged as part of the worst case BI study. This strategy may eliminate second guessing and questions as the CQV activities proceed and the protocols and summary reports are approved. 4. Aeration Study The aeration study is executed by running the final cycle that was determined through the cycle development studies. This final cycle is then initiated. a. When the cycle transitions to the aeration phase, use a Draeger hand pump and Draeger tubes to evaluate the residual H2O2 levels at various time points. b. When two consecutive residual H2O2 readings are in the same Draeger Tube range, the aeration endpoint is established. However, the endpoint can only be established if the minimum required H2O2 level has been achieved in accordance with the residual ppm level defined in the User Requirements Specification (URS). Note: The URS endpoint is either established as an Operator Exposure Level (OEL) requirement of ≤ 1ppm or a product specific requirement to prevent oxidation and degradation of the drug product being filled within the isolator environment. 5. Performance Qualification The PQ for the H2O2 decontamination cycle shall be per formed by running three consecutive decontamination cycles with three BIs per location. The PQ runs will use the parameters and conditions that were established during the cycle development work. If the filling system requires CIP and SIP, these activities should be included in the PQ test plan and protocols. An alter native approach is to use a reduced decontamination phase of vthe decontamination cycle to execute the PQ for a more challenging qualification. 1. The number of BIs locations used in the PQ can be reduced vs. the total number exposed during the worst case study. 2. The reduced number of BIs can be based off the findings and results for each of the individual tests during cycle development. For example, the number of BIs for the PQ Study can be determined from the worst case locations identified during Temperature and Humidity Mapping, chemical indicator study and from the airflow pattern testing. Once this strategy is defined and the number of BIs is determined, this should be applied to the periodic requalification procedure. About the Author Kevin Debbs, CPIP Kevin Debbs is a Senior Pharmaceutical Specialist at CRB with over 23 years of aseptic manufacturing experience in the pharmaceutical and biologics industries. He has designed, constructed and qualified new facilities, equipment systems and manufacturing processes. He has successfully launched new products and line extensions, while continuously improving product quality, patient safety and value to the organization. Kevin has also led teams in the design, construction, commissioning and qualification of manufacturing plants, laborites and support services. His expertise includes aseptic and sterile manufacturing processes, including isolation technology and lyophilization. He is skilled at preparing and executing protocols, designing experiments, statistical process control, performing risk analysis and engineering evaluations to ensure designs and processes meet quality and performance standards. He has developed User Requirement Specifications (URS), Design Qualifications (DQ), System & Component Impact Assessments, Validation Plans and IQ/ OQ protocols. In additions, Kevin is able to perform job safety analysis to identify and mitigate operational hazards to minimize or eliminate costs related to health, safety and ergonomic injuries. Contact Kevin at kevin.debbs@crbusa.com or 919-852-5494. 13 Advertising Opportunities in ISPE-CaSA 2016 Electronic Newsletter The ISPE CaSA Chapter produces six e-newsletters per year. ISPE CaSA sends out the newsletters via email and via Web link to all of our Chapter Members throughout the Southeastern U.S., which reach top-notch pharmaceutical, biotechnology, and bio-science professionals and managers. These newsletters are also posted on our Web site so your ad can be accessed by interested visitors to our site. The cost for a full color business-card-sized ad is $750 per year. There is also the ability of positioning your ad on the front page of the newsletter for an additional $750 per year for six issues. Space limits the number of front page to only four, and is offered to the first four paid advertisers on a first-come, first-served basis. Also, if you would you like to have your targeted customers go directly to your website by simply clicking on your ad; a hot-link can be added to your submitted ad file for an additional $500.00 for the entire year. You may choose one of the special offers below: $1,500 Full-color ad for six issues on the front page of each newsletter ($250/issue) $1,500 Full-color double-sized ad for two issues ($250/issue) $750 Full-color ad for two issues ($125/issue) $200 Full-color ad in 1 newsletter of your choice ($200) $500 Add a hot link for directing customers to your website by a simple click ($500) We hope you will take advantage of these opportunities and advertise in the 2015 ISPE CaSA e-newsletter. To reserve a placement of your ad for 2015 please contact the ISPE-CaSA Headquarters at 919-573-5442 or via e-mail at info@ispecasa.org. Deadline for 2016 advertisers to be in the February 2016 issue is January 22. You will be notified via e-mail or telephone when your advertisement has been accepted by the ISPE-CASA Newsletter Committee and asked to submit your advertisement digitally. Full-color business card-sized ads (3.5” x 2”) may contain your logo or other artwork. Artwork should be sent directly to newsletter@ispecasa.org. We ask that your text be no smaller than 12 pt so that the text is easily readable in the electronic format. PDF, JPEG, or TIF formats, are easiest for us to work with. Space is limited, sign up today! 14 ISPE CaSA Chapter E-Newsletter Ads Newsletter Ads Work for Your Business! Our Chapter produces six enewsletters per year, and we depend on the support of our advertisers. We send out the newsletters via e-mail and via web link to all of our Chapter Members throughout the Southeastern U.S. That means you get targeted access to top-notch pharma, biotech, and bio-science professionals and managers. These newsletters are also posted on our website so your ad can be accessed by interested visitors to our site. Best of all, the cost is only $750 for your full color, business-card-sized ad for six insertions. That’s only $750 for targeted advertising in full color for an entire year! Ask About HOT LINKS!! Would you like to have targeted customers simply click on your ad and get right to your website? A hot-link can be added to your ad, connecting readers directly to your company website for an additional $500.00 for a whole year. If you are interested in advertising with the ISPE CaSA e-newsletter, please contact our Chapter headquarters at: ISPE-CaSA 1500 Sunday Drive Suite 102 Raleigh, NC 27607 919-573-5442 info@ispeCaSA.org You will be notified via e-mail or telephone when your advertisement has been accepted by the ISPE CaSA Newsletter Committee and asked to submit your advertisement digitally. Full-color business card-sized ads (3.5” x 2”) may contain your logo or other artwork. Artwork should be sent directly to info@ispeCaSA.org. We ask that your text be no smaller than 12 pt so that the text is easily readable in the electronic format. PDF, JPEG or TIF formats are easiest for us to work with. Space is limited, sign up today! 15 ISPE Carolina-South Atlantic Chapter Newsletter 1500 Sunday Drive, Suite 102, Raleigh, NC 27607 Tel: 1-919/573-5442 • Fax: 1-919/787-4916 rich.stanfield@cagents.com Would you, or someone you know, like to publish your technical content in these pages? Please submit any and all technical content to info@ispecasa.org or send directly to our Newsletter Chair at rich.stanfield@cagents.com. EDITORIAL POLICY Articles should be written for technical professionals in the pharmaceutical, biotechnology, and medical device industries. The author is responsible for the accuracy and correctness of all statements contained in the manuscript (ISPE Carolina-South Atlantic Chapter assumes no liability.) Manuscripts should be submitted with a brief, three to four sentence synopsis of the article, as well as a brief biographical statement about the author that includes educational background, title and job affiliation, job responsibilities and major areas of accomplishment. A word to the ISPE CaSA Newsletter advertisers: Thank you all for your continued support. Without it we could not have the wonderful support staff to get our ISPE CaSA Members the news in such a timely and professional fashion. If you have updates to your advertisements or find any other error, please contact us so that we can serve you better.