Damaged or Missing Parts Procedure

advertisement

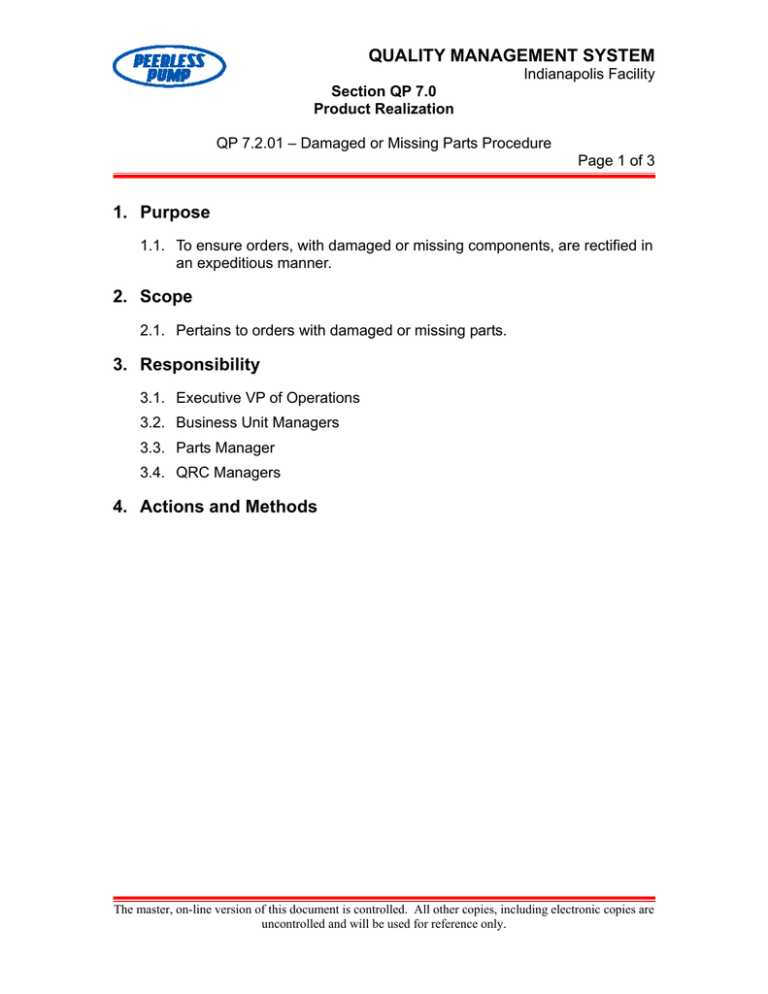

QUALITY MANAGEMENT SYSTEM Indianapolis Facility Section QP 7.0 Product Realization QP 7.2.01 – Damaged or Missing Parts Procedure Page 1 of 3 1. Purpose 1.1. To ensure orders, with damaged or missing components, are rectified in an expeditious manner. 2. Scope 2.1. Pertains to orders with damaged or missing parts. 3. Responsibility 3.1. Executive VP of Operations 3.2. Business Unit Managers 3.3. Parts Manager 3.4. QRC Managers 4. Actions and Methods The master, on-line version of this document is controlled. All other copies, including electronic copies are uncontrolled and will be used for reference only. QUALITY MANAGEMENT SYSTEM Indianapolis Facility Section QP 7.0 Product Realization QP 7.2.01 – Damaged or Missing Parts Procedure Page 2 of 3 D A M A G E D O R M IS S IN G P A R TS P O LIC Y It is the intent of Sterling Fluid System s (U SA ), Inc. to provide products as desired by the custom er. H ow ever, occasionally products m ay be supplied incorrectly. A t these tim es, Sterling's desire is to correct the problem as quickly as possible. D am aged or M issing P arts P olicy G uidelines: 1. C ustom er m ust supply O riginal Job N um ber or Serial N um ber. 2. The party w ho files the freight claim is determ ined by the agreed shipping term s on the order. E xam ple, if FC A Indianapolis is the shipping term s and dam age occurs in transit, then the custom er files the freight claim . 3. A C ustom er C om plaint Form (via E xtranet for business partners or via a sales office for end users) should be used as the m ethod to request replacem ent shipm ents. If original order w as a parts order, send custom er com plaint to P arts D epartm ent. If the original shipm ent w as a pum p order, send custom er com plaint to the respective Business U nit. (If the E xtranet is not available, contact the B usiness U nit C ustom er S ervice R epresentative or B usiness U nit M anager.) 4. D am aged or incorrect shipm ents m ust be noted on the proof of delivery by the custom er/carrier at the tim e of delivery. 5. D efective parts (as opposed to dam aged or m issing item s) are subject to the w arranty policy, not this policy. A C hargeable O rder w ill be E ntered if any of the follow ing apply: 1. 2. 3. 4. 5. O riginal Job N um ber or S erial N um ber N ot Supplied. R equest is 30 D ays past date of shipm ent - U S only. International S hipm ents past 2 w eeks from delivery to job-site. R M A m aterial involved. Freight D am aged not noted on proof of delivery. Freight D am age reported after 10 w orking days of shipm ent. (M ost carriers require freight claim s to be filed w ithin 15 w orking days) C ustom er M issing P art The flow chart below show s the D am aged or M issing P arts P olicy P rocedure: C ustom er or S ales fills out C om plaint Form M issing or D am aged A fter A rrival? Y es C ustom er R eceives D am aged P art M issing or D am aged B efore S hipm ent? M issing or D am aged by C arrier? No Y es Yes Factory E nter NO CHARGE O rder for R eplacem ent Yes C ustom er R eceives W rong P art No C ustom er ordered W rong P art? C ustom er or S ales fills out C om plaint Form C ustom er E nter C H A R G E A B LE O rder for R eplacem ent C ustom er or S ales fills out C om plaint Form Factory E nters C H A R G E A B LE R eplacem ent O rder No Factory issue R M A to C ustom er & Issue C redit to C ustom er w hen O riginal P art R eceived COL or PPA C ustom er files freight claim and enters C H A R G E A B LE order FA Factory files freight claim and supplies NO CHARGE replacem ent Signature of receipt of product by the custom er and/or carrier indicates an acceptance of responsibility for contents and indicates that the shipm ent has been verified and inspected by the receiving party. Factory m ay exercise the right to enter a chargeable order w hen a signature of receipt is verified. The master, on-line version of this document is controlled. All other copies, including electronic copies are uncontrolled and will be used for reference only. QUALITY MANAGEMENT SYSTEM Indianapolis Facility Section QP 7.0 Product Realization QP 7.2.01 – Damaged or Missing Parts Procedure Page 3 of 3 5. Associated Documents 5.1. None 6. Records 6.1. All records created as a result of this policy will be viewed as indicator(s) of quality and will be controlled and retained as detailed in QP 4.2. Revision Record Rev. 0 Date 8-1-2003 Change by Description of Change Initial Release of the ISO 9001: 2000 Manual The master, on-line version of this document is controlled. All other copies, including electronic copies are uncontrolled and will be used for reference only.