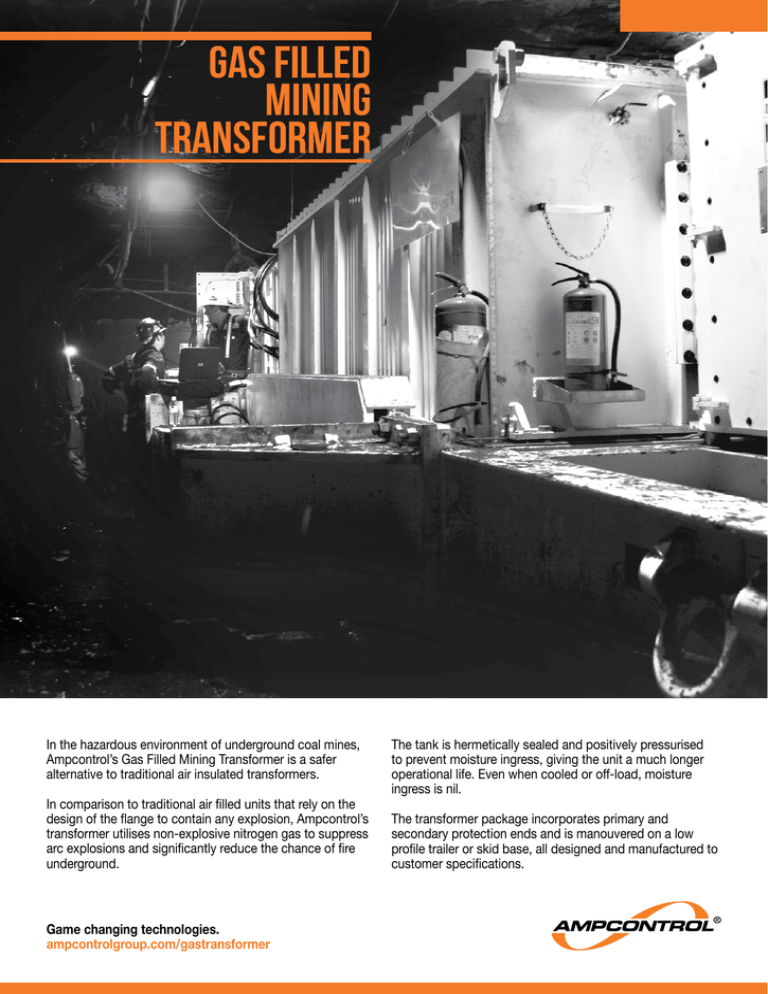

gas filled mining transformer

advertisement

gas filled mining transformer In the hazardous environment of underground coal mines, Ampcontrol’s Gas Filled Mining Transformer is a safer alternative to traditional air insulated transformers. In comparison to traditional air filled units that rely on the design of the flange to contain any explosion, Ampcontrol’s transformer utilises non-explosive nitrogen gas to suppress arc explosions and significantly reduce the chance of fire underground. Game changing technologies. ampcontrolgroup.com/gastransformer The tank is hermetically sealed and positively pressurised to prevent moisture ingress, giving the unit a much longer operational life. Even when cooled or off-load, moisture ingress is nil. The transformer package incorporates primary and secondary protection ends and is manouvered on a low profile trailer or skid base, all designed and manufactured to customer specifications. applications The transformer is ideal for use in underground coal mines where SANS 60076:15 certification is required due to hazardous atmosphere. The unit also has positive safety implications for the mineral and metal mining industry. The unit powers continuous miners, conveyors, shuttle cars and any electrical equipment. improved safety The transformer has increased safety benefits over traditional air filled models. By utilising inert gas nitrogen, arc explosions are suppressed and reliance on the flange design to quell the explosion is reduced. For personnel working in hazardous environments, this means dramatically reduced chances of fire hazard. reduced maintenance Service required to maintain the unit is minimal. With moisture ingress eliminated, the life of the transformer is extended and monitoring of the internal gas pressure is the only requirement. COMPACT DESIGN Supplied on a wheeled trailer or skid base, the transformer is designed to be lighter, with a lower profile and smaller footprint than air cooled units. Ampcontrol Africa 375 Bergvlei Road, Shop 9 Ackrupta Park Wadeville Ext 5 Gauteng Province Telephone: +27 11 902 9297 Email: sasales@ampcontrolgroup.co.za specifications Ratings Voltage ratio 250kVA - 7MVA HV 11,000V/6,600V LV 415V/1,100V/3,300V Cooling medium Nitrogen Temperature rise Winding 150°C Enclosure 100°C Tapping range Frequency Certification +5 to -5% 50Hz SANS 60076:15 features & benefits Features Inert nitrogen gas insulation Compact design Benefits Reduced risk of explosions, increased personnel safety Light, low profile unit with manoeuvrable trailer or skid base Hermetically Longer service life through sealed, positively elimination of dust and moisture pressurised tank ingress No serviceable Increased production through parts reduced maintenance and operational downtime In house designed Easy tap switch adjustment with tap switch externally accessed switch