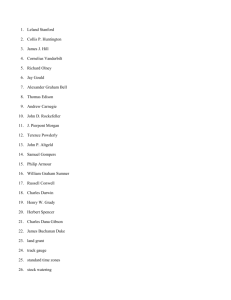

guidelines for railroad grade separation projects

advertisement