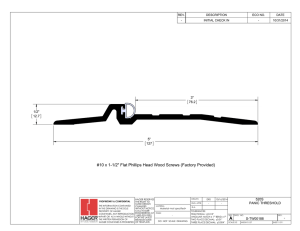

COMPONENT PARTS 1. MARK AND DRILL HOLES (RIGHT HAND

advertisement

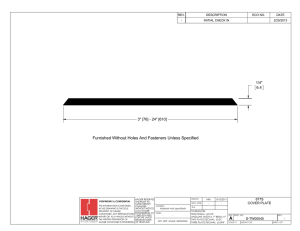

5125, 5106, 5108, 5961 Heavy Duty Parallel Arm Installation Instructions Meets ANSI A156.4 • Hollow-metal doors require channel or box-type reinforcement when thru-bolt mount is specified. • Hold open arms are not permitted on fire doors. • Sex-bolts may be required for wood or plastic faced fire door mounting. • Minimum thickness recommended for reinforcements in hollow metal doors and frames: (12GA) • Dimensions are based on standard doors and frames with 1/8" clearance, 5/8" stops, and square edge doors. Handing of Door Left Hand Right Hand These door closers should NOT be installed on the exposed side (weather side) of exterior doors. TOOLS REQUIRED METAL TOOLS REQUIRED WOOD METAL WOOD Self Drilling Screws Wood and Metal Self Drilling Screws Wood and Metal Sleeve Nut and Bolt Sleeve Nut and Bolt Drill 9/32" thru from Closer Side 3/8" Drill other Side For wood, drill 3/16" hole For wood, drill 3/16" hole Drill 9/32" thru from Closer Side 3/8" Drill other Side Machine Screws #7 Machine Screws 3/16" #7 Check building and fire codes to 3/16" #7 Drill, 1/4"- 20 Tap 1/4"- 20 #7 Drill, 1/4"- 20 Tap 1/4"- 20 Check fire codesrequires to seebuilding if your and application see application requires theif your use of sleeve nuts and bolts. the use of sleeve nuts and bolts. COMPONENT PARTS PARTS COMPONENT COMPONENT PARTS POWER ADJUSTMENT SHAFT SHAFT POWER ADJUSTMENT INSERTCUTOUTS CUTOUTS INSERT LATCH VALVE BACKCHECKBACKCHECK VALVE VALVE SELECTOR VALVE COVER INSERT INSERT COVER LATCH VALVE LATCH VALVE POWER ADJUSTMENT SHAFT SWEEP VALVE CLOSER COVER CLOSER BODY CLOSER COVER CLOSER BODY CLOSER BODY BACKCHECK VALVE SWEEP VALVE SCREW PACK SWEEP VALVE SCREW PACK 1. MARK AND DRILL HOLES (RIGHT HAND SHOWN) Locate the arm and degree of opening for this installation. Use the charts below to mark/drill/tap the 1/4-20 holes for the frame soffit and/or rabbet. Use the charts on the following page to mark/drill/tap 1/4-20 holes in the door. A 1 11/16" 42.9 1 1/16" 27 HINGE PIVOT 5/16" 8 5125 EXTRA HEAVY DUTY STOP ARM Dim. “A” 10-1/2" 9-1/4" 8-3/8" FRAME STOP DOOR 5106 EXTRA HEAVY DUTY ARM & 5108 EXTRA HEAVY DUTY HOLD OPEN ARM X 3/8" 9.5 1 3/4" 44.8 27/32" 21.4 X Door Opening w/ Stop Door Opening w/o Stop 90° 100° 100° 100 - 120° 110° 120 - 150° PREP THIS HOLE IN THE FRAME SOFFIT OR RABBET IF USING THE 5106 OR 5108 ARM. PREP THESE (2) HOLES IN THE FRAME SOFFIT OR RABBET IF USING THE 5105 OR 5960 ARM. 2 11/32" 59.5 Dim. “A” 9-3/4" 6-1/4" Door Opening up to 110° up to 180° 5961 EXTRA HEAVY DUTY HOLD OPEN STOP ARM: Dim. “A” 10-7/16" 9-1/4" 8-3/8" Door Opening w/ Stop Door Opening w/o Stop 90° 100° 100° 100 - 120° 110° 120 - 150° HAGER COMPANIES • 139 Victor Street, St. Louis, MO 63104 • 800-325-9995 • Fax (800) 782-0149 • www.hagerco.com REVISIONS REV. DESCRIPTION DATE 5125, 5106, 5108, 5961 Heavy Duty Parallel Arm Installation Instructions Meets ANSI A156.4 1. MARK AND DRILL HOLES (CONTINUED) 1 1/2" 38.1 STOP FACE 8 1/4" 209.6 1 1/2" 38.1 5125 Extra Heavy Duty Stop Arm & 5961 Extra Heavy Duty Hold Open Stop Arm: 3/4" 19.2 2 5/16" 58.7 2 1/4" 57 15/16" 23.7 1" 25.4 8-3/4" 7-11/16" 90° 100° 7-5/8" 6-9/16" 100° 100 - 120° 6-5/8" 5-9/16" 110° 120 - 150° C Dim. “B” Dim. “C” Door Opening 8" 6-15/16" up to 110° 4-1/2" 3-7/16" up to 180° B Prepare these 4 holes for standard installation of closer to door without drop plate. X Prepare these 4 holes for 5110 drop plate only Door Opening w/o Stop **Dim. “C” 5106 Extra Heavy Duty Arm & 5108 Extra Heavy Duty Hold Open Arm: 1" 25.4 3" 76.2 Door Opening with Stop Dim. “B” **Needed only if using 5110 drop plate *This table was made using 4 1/2” wide hinges. Use of larger hinges or swing clear hinges will yield different results. REVISIONS Note: Drop plate works with a minimum top rail of 2 1/2”. DESCRIPTION REV. DATE 2. ARM & CLOSER BODY INSTALLATION • Screw body to the door using (4) 1/4-20 x 3" screws. The tube 5th HOLE IN BRACKET USED WITH end of the closer must face the lock stile of door. SPACER BLOCK IF FRAME HAS NARROW SOFFIT • Screw arm bracket to the frame soffit using (5) 1/4-20 x 1 1/2" HAGER RESERVES THE RIGHT TO MAKE DESIGN THE INFORMATION CONTAINED MATERIAL CHANGES IN THIS DRAWING IS THE SOLE Material <not specified> WITHOUT NOTICE. CALL HAGER PROPERTY OF HAGER COMPANIES. ANY REPRODUCTION ENGINEERING AT FINISH 1-800-325-9995 INPART OR AS A WHOLE WITHOUT FOR THE LATEST THE WRITTEN PERMISSION OF REVISION DATE DO NOT SCALE DRAWING HAGER COMPANIES IS PROHIBITED. OF TEMPLATE. PROPRIETARY & CONFIDENTIAL - the way to make mounting screws. Do not tighten screws all the- arm to- the closer easier. DRAWN ENG. APPR. Q.A. TOLERANCES: FRACTIONAL: 0.015" ANGULAR: MACH: 1 BEND: 1 TWO PLACE DECIMAL: 0.01" THREE PLACE DECIMAL: 0.004" SIZE DWG. NO. FRAME RABBET REV. A 5100 drop plate dimensions hd arm SCALE:1:24 WEIGHT: 239.06 SHEET 1 OF 1 ARM BRACKET 5th HOLE SPACER BLOCK Before mounting closers, make sure selector valve (found on back of closer) is screwed in. The fifth hole spacer shown above can be used when a narrow soffit prevents normal mounting. Drill/tap a 1/4-20 hole in the REVISIONS frame rabbet. Place the spacer between the bracket and frameDATE REV. DESCRIPTION and tighten using a 1/4-20 x 2” screw. CLOSER BODY INSTALLATION (OPT DROP PLATE) 5th HOLE IN BRACKET USED WITH SPACER BLOCK IF FRAME HAS NARROW SOFFIT • If using a drop plate, screw the drop plate to the door using 1/4-20 screws. Screw closer to the drop plate using 7/16" long machine screws. HAGER RESERVES DRAWN - - THE RIGHT TO ENG.• APPR. HAGER COMPANIES • 139 Victor Street, St. Louis, MO 63104 • 800-325-9995 Fax (800) - • www.hagerco.com - 782-0149 MAKE DESIGN PROPRIETARY & CONFIDENTIAL THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY OF HAGER COMPANIES. ANY REPRODUCTION MATERIAL CHANGES 2 specified> Material <not WITHOUT NOTICE. CALL HAGER ENGINEERING AT FINISH Q.A. TOLERANCES: FRACTIONAL: 0.015" - REVISIONS REV. DESCRIPTION DATE 5125, 5106, 5108, 5961 Heavy Duty Parallel Arm Installation Instructions Meets ANSI A156.4 3. MOUNT ARM TO CLOSER HINGE PIVOT REVISIONS SPINDLE REV. DOOR 45 DESCRIPTION • Use an adjustable wrench to rotate the DATE bottom pinion shaft about 45 degrees in the direction away from the door. ROTATE WRENCH AWAY FROM DOOR • Place arm on top pinion while holding pinion in position. • Release hold on pinion shaft and attach arm to closer using pinion screw. Tighten bracket to frame if it was DATE left loose during arm installation. REVISIONS REV. DESCRIPTION 5125 EXTRA HEAVY DUTY STOP ARM HAGER RESERVES THE RIGHT TO MAKE DESIGN THE INFORMATION CONTAINED MATERIAL CHANGES IN THIS DRAWING IS THE SOLE Material <not specified> WITHOUT NOTICE. CALL HAGER PROPERTY OF HAGER FINISH ENGINEERING AT COMPANIES. ANY REPRODUCTION 1-800-325-9995 INPART OR AS A WHOLE WITHOUT FOR THE LATEST THE WRITTEN PERMISSION OF REVISION DATE DO NOT SCALE DRAWING HAGER COMPANIES IS PROHIBITED. OF TEMPLATE. PROPRIETARY & CONFIDENTIAL DRAWN - - ENG. APPR. - - - Q.A. TOLERANCES: FRACTIONAL: 0.015" ANGULAR: MACH: 1 BEND: 1 TWO PLACE DECIMAL: 0.01" THREE PLACE DECIMAL: 0.004" SIZE REV. DWG. NO. A SCALE:1:24 5100 rotate wrench hd arm WEIGHT: 235.77 SHEET 1 OF 1 REVISIONS REV. DESCRIPTION DATE CAN BE MOUNTED TO OPEN UP TO 90 / 100 / 110 HAGER RESERVES THE RIGHT TO MAKE DESIGN THE INFORMATION CONTAINED MATERIAL CHANGES IN THIS DRAWING IS THE SOLE Material <not specified> WITHOUT NOTICE. WRENCH CALL HAGER PROPERTY OF HAGER FINISH ENGINEERING AT COMPANIES. ANY REPRODUCTION 1-800-325-9995 INPART OR AS A WHOLE WITHOUT FOR THE LATEST THE WRITTEN PERMISSION OF REVISION DATE DO NOT SCALE DRAWING HAGER COMPANIES IS PROHIBITED. OF TEMPLATE. PROPRIETARY & CONFIDENTIAL AGER RESERVES E RIGHT TO AKE DESIGN MATERIAL HANGES DRAWN - - ENG. APPR. - - - Q.A. TOLERANCES: STOP FRACTIONAL: 0.015" REV. SIZE DWG. NO. ANGULAR: MACH: 1 BEND: 1 MOUNTING LOCATIONS TWO PLACE DECIMAL: 0.01" 5100 PA EHD ARM BOTTOM VIEW SCALE:1:24 WEIGHT: 235.80 SHEET 1 OF 1 THREE PLACE DECIMAL: 0.004" A Removable stop can be used for right hand or left hand application (currently shown in right hand application.) Stop can only be removed when arm is not attached to the frame. Use a hex wrench to unscrew stop and move it. See picture to the left. FILLER PLUG STOP PROPRIETARY & CONFIDENTIAL THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY OF HAGER COMPANIES. ANY REPRODUCTION INPART OR AS A WHOLE WITHOUT THE WRITTEN PERMISSION OF HAGER COMPANIES IS PROHIBITED. HAGER COMPANIES • 139 Victor Street, St. Louis, MO 63104 • 800-325-9995 • Fax (800) 782-0149 • www.hagerco.com DRAWN ENG. APPR. Q.A. - - - - 3 - HAGER RESERVES THE RIGHT TO MAKE DESIGN MATERIAL CHANGES Material <not specified> WITHOUT NOTICE. CALL HAGER ENGINEERING AT FINISH 1-800-325-9995 FOR THE LATEST REVISION DATE DO NOT SCALE DRAWING OF TEMPLATE. REVISIONS REV. Meets ANSI A156.4 5106 EXTRA HEAVY DUTY ARM CAN BE MOUNTED TO OPEN UP TO 110 OR UP TO 180 REVISIONS REV. DESCRIPTION BOTTOM VIEW DATE 5108 EXTRA HEAVY DUTY HOLD OPEN ARM HAGER RESERVES THE RIGHT TO MAKE DESIGN CONTAINED MATERIAL CHANGES THE SOLE Material <not specified> WITHOUT NOTICE. CALL HAGER ER REPRODUCTION ENGINEERING AT FINISH 1-800-325-9995 HOLE WITHOUT FOR THE LATEST SSION OF REVISION DATE DO NOT SCALE DRAWING S IS PROHIBITED. OF TEMPLATE. ONTAINED HE SOLE DATE 5125, 5106, 5108, 5961 Heavy Duty Parallel Arm Installation Instructions NFIDENTIAL IDENTIAL DESCRIPTION DRAWN - - ENG. APPR. - - - PROPRIETARY & CONFIDENTIAL A HAGER RESERVES THE RIGHT TO MAKE DESIGN MATERIAL CHANGES Mater WITHOUT NOTICE. CALL HAGER ENGINEERING AT FINISH 1-800-325-9995 FOR THE LATEST REVISION DATE DO NO OF TEMPLATE. CAN BE MOUNTED TO OPEN UP TO 110 OR UP TO 180 Q.A. TOLERANCES: FRACTIONAL: 0.015" SIZE DWG. NO. ANGULAR: MACH: 1 BEND: 1 TWO PLACE DECIMAL: 0.01" 5100 PA EHD ARM SCALE:1:32 WEIGHT: 41.60 THREE PLACE DECIMAL: 0.004" REV. MOUNTING LOCATIONS SHEET 1 OF 1 THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY OF HAGER COMPANIES. ANY REPRODUCTION INPART OR AS A WHOLE WITHOUT THE WRITTEN PERMISSION OF HAGER COMPANIES IS PROHIBITED. BOTTOM VIEW To adjust hold open setting, open the door to about 5 degrees less then the desired position. Use wrench to securely tighten nut on the hold open arm. (Currently shown in right-handed application.) HAGER RESERVES THE RIGHT TO HAGER COMPANIES MAKE DESIGN MATERIAL CHANGES Material <not specified> WITHOUT NOTICE. CALL HAGER ENGINEERING AT FINISH DRAWN •ENG. 139 Victor Street, St.- Louis, MO 63104 • 800-325-9995 • Fax (800) 782-0149 • www.hagerco.com PROPRIETARY & CONFIDENTIAL APPR. Q.A. TOLERANCES: 4 HAGER RESERVES THE RIGHT TO MAKE DESIGN THE INFORMATION CONTAINED MATERIAL CHANGES IN THIS DRAWING IS THE SOLE Mate NOTICE. USE SUPPLIEDWITHOUT WRENCH CALL HAGER PROPERTY OF HAGER REVISIONS REV. DESCRIPTION DATE 5125, 5106, 5108, 5961 Heavy Duty Parallel Arm Installation Instructions Meets ANSI A156.4 5961 EXTRA HEAVY DUTY HOLD OPEN ARM CAN BE MOUNTED TO OPEN UP TO 90 / 100 / 110 WRENCH STOP BOTTOM VIEW TIGHTEN THUMBTURN BY ROTATING 90 DEGREES. LOOSEN BY ROTATING 90 DEGREES IN EITHER DIRECTION. THUMBTURN HAGER RESERVES THE RIGHT TO MAKE D ESIGN ORMATION CONTAINED MATERIAL CHANGES DRAWING IS THE SOLE Material <not specified> WITHOUT NOTICE. CALL HAGER TY OF HAGER NIES. ANY REPRODUCTION ENGINEERING AT FINISH 1-800-325-9995 OR AS A WHOLE WITHOUT FOR THE LATEST TTEN PERMISSION OF REVIS ION DATE DO NOT SCALE DRAWING COMPANIES IS PROHIBITED. OF TEMPLATE. TARY & CONFIDENTIAL DRAWN - - ENG. APPR. - - - Removable stop can be used for right hand or left hand application (currently shown in right hand application). Stop can only be removed 0.015" RE . SIZE DWG. NO. ANGULAR: MACH: 1 BEND: 1 arm is not attached to the frame. Use a hex wrench to unscrew A PAwhen EHD ARM MOUNTING LOCATIONS TWO PLACE DECIMAL: 0.01" 5100 SCALE:1:32 WEIGHT: 42.45 1 OF 1 to the left. To engage hold open feature, THREE PLACE DECIMAL: 0.004" stop and move it. See SHEET picture open door to the stop and rotate thumbturn 90 degrees. To release, rotate thumbturn 90 degree in either direction. Q.A. FILLER TOLERANCES: PLUG FRACTIONAL: STOP 4. ADJUSTMENTS 5. INSTALL COVER See Adjustments on Page 6 for setting Spring Power, Sweep Speed, Latch Speed, and Backcheck. NOTE: Do not fully unscrew valves or hydraulic fluid will leak and closer will no longer be functional. COVER Slide cover over closer body and secure by tightening screws. HAGER COMPANIES • 139 Victor Street, St. Louis, MO 63104 • 800-325-9995 • Fax (800) 782-0149 • www.hagerco.com 5 5125, 5106, 5108, 5961 Heavy Duty Parallel Arm Installation Instructions Meets ANSI A156.4 ADJUSTMENTS (USE 5/32" HEX WRENCH FOR THESE ADJUSTMENTS) SWEEP SPEED LATCH SPEED Note: Adjust closing time speed between 3 and 7 seconds from 90° to 0°. Greater closing times may be required for elderly or handicapped. BACKCHECK Adjust latch speed so door completely closes and latches. OPTIONAL DELAY ACTION OR Adjust delay action accordingly to obtain desired delay time. Adjust backcheck accordingly to prevent excessive opening speed. Exterior (and Vestibule) Door Width Minimum Door Width (24") SPRING POWER ADJUST (SIZING IN ACCORDANCE TO BHMA/ANSI 24" - 30" - 36" - 42" - 48" 156.4) (610mm) (762mm) (914mm) (1067mm) (1219mm) Regular Arm & TABLE OF SIZES Closer is shipped set to size 3. To change the closer size, use a Top Jamb hex wrench to rotate the spring power adjust. Follow the chart to make the correct number of 360° turns to set the closer sizeParallel Arm appropriately for the door application. Size 3 Size 4 Size 5 Size 6 (12cw) (8cw) Door (4cw) (0)Exterior (and Vestibule) Width Exterior (and Vestibule) Door Width Door Width 5 (24") 4 Size Size 3 SizeMinimum - 30" - (12cw) (4cw)24" (8cw) 36" 48" (24") Minimum42" Door Width (610mm) (762mm) (914mm) (1067mm) (1219mm) 24" - 30" - 36" - 42" - 48" Regular Arm & Interior Size 6 (1067mm) (1219mm) Size 5 (914mm) 4 Width Size(610mm) 3 Size (762mm) Door (4cw) (8cw) (12cw) (0) Top Jamb The number of turns is an approximation and does not account for environmental or door hardware affects. Minimum Door Width (24") 24" cw = clockwise ccw = counterclockwise (610mm) (762mm) (865mm) (965mm) (1219mm) (1372mm) (1524mm) 4 Size 3DoorSize Width Parallel ArmInterior Regular Arm & Top Jamb cw = clockwise ccw = counterclockwise (Use 5/32" Hex Wrench for this adjustment) Regular Arm Size 5 4 Size 5 Size 6 Size 43 Size Size&3 Size (4cw)- (8cw) (0) - (12cw) (4cw) Jamb 30" -Top34" 38" 48" - (8cw) 54" - (12cw) 60" Parallel Arm Size 5 (4cw) (8cw) (12cw) Size 1 Size 2 Size 3 Size 4 Size 5 Size 6 - 30" - (0) - 54"(12cw) - 60" (8cw) (8ccw) 24"(4ccw) 34" - (4cw) 38" - 48" Minimum Door Width (24") (610mm) (762mm) (865mm) (965mm) (1219mm) (1372mm) (1524mm) Interior Door Width 5 (24") 4 Size Size 1 Size 2 Size 3 Size Minimum Door Width Parallel ArmRegular Arm & Size 1 Size 2 Size 3 Size 4 Size 5 Size 6 (12cw) (4ccw) Top Jamb (Use 5/32" Hex Wrench for this adjustment) cw = clockwise ccw = counterclockwise (0) (4ccw) (4cw) (0) (8cw) (4cw) (8ccw) - 24" Parallel Arm Size 1 Size 2 (4ccw) (0) Regular Arm & Top Jamb (Use 5/32" Hex Wrench for this adjustment) 30" 34" (8cw) 38" Parallel Arm Size 3 (4cw) 48" - 54" - 60" Size 4 Size 5 (8cw) (12cw) Size 1 Size 2 Size 3 (0) (8ccw) (4ccw) Size 4 (4cw) Size 1 Size 2 (4ccw) (0) Size 4 Size 5 (8cw) (12cw) Size 3 (4cw) An incorrectly installed or improperly adjusted door closer can cause property damage or personal injury. These installation instructions should be followed to avoid the possibility of misapplication or misadjustment. HAGER COMPANIES • 139 Victor Street, St. Louis, MO 63104 • 800-325-9995 • Fax (800) 782-0149 • www.hagerco.com 6 (12cw) (610mm) (762mm) (865mm) (965mm) (1219mm) (1372mm) (1524mm) Size 5 Size 6 (8cw) (12cw)