SS1003_CDT_GRC_CmbfCN_2p_v7

6/18/10

11:27 AM

Page 1

RIGID STEEL

CONDUIT (GRC)

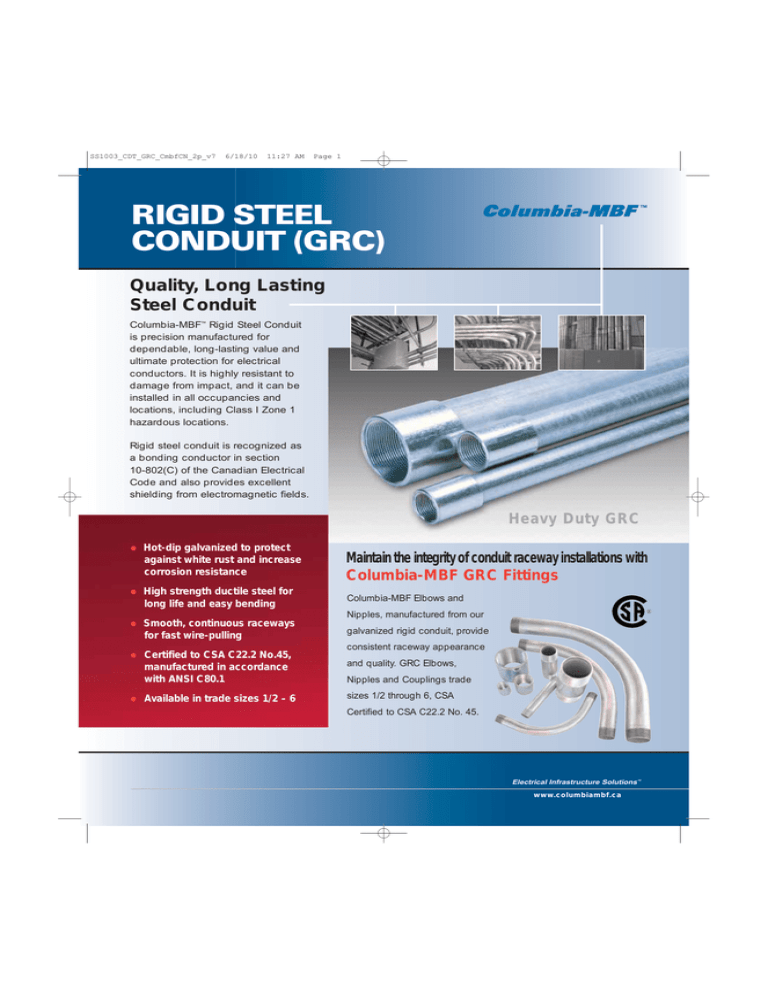

Quality, Long Lasting

Steel Conduit

Columbia-MBF™ Rigid Steel Conduit

is precision manufactured for

dependable, long-lasting value and

ultimate protection for electrical

conductors. It is highly resistant to

damage from impact, and it can be

installed in all occupancies and

locations, including Class I Zone 1

hazardous locations.

Rigid steel conduit is recognized as

a bonding conductor in section

10-802(C) of the Canadian Electrical

Code and also provides excellent

shielding from electromagnetic fields.

Heavy Duty GRC

galvanized to protect

• Hot-dip

against white rust and increase

corrosion resistance

strength ductile steel for

• High

long life and easy bending

•

Smooth, continuous raceways

for fast wire-pulling

•

Certified to CSA C22.2 No.45,

manufactured in accordance

with ANSI C80.1

•

Available in trade sizes 1/2 – 6

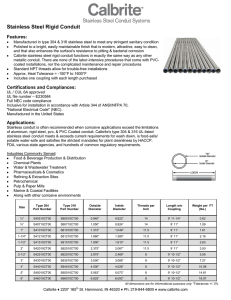

Maintain the integrity of conduit raceway installations with

Columbia-MBF GRC Fittings

Columbia-MBF Elbows and

Nipples, manufactured from our

galvanized rigid conduit, provide

consistent raceway appearance

and quality. GRC Elbows,

Nipples and Couplings trade

sizes 1/2 through 6, CSA

Certified to CSA C22.2 No. 45.

Electrical Infrastructure Solutions™

www.columbiambf.ca

SS1003_CDT_GRC_CmbfCN_2p_v7

6/18/10

11:27 AM

Page 2

RIGID STEEL

CONDUIT (GRC)

Specifications

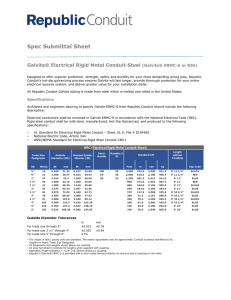

Weights and Dimensions for Galvanized Rigid Steel Conduit

FULL ELECTRICAL SYSTEM PROTECTION

Manufactured from high-strength steel, Columbia-MBF

RIGID combines damage-resistant strength with ductility

to assure easy bending, cutting and joining. It also

provides smooth, continuous raceways for fast wirepulling. No need to worry about damage to the conduit

system even when pulling through multiple 90° bends.

™

Approx. Wt.* Per Nominal Outside

100 Ft. (30.5M)

Diameter1

Designator

in.

mm

in.

mm

ft.

m

16

82

37.2

0.840

21.3

0.104

2.60

1000

305.0

21

109

49.4

1.050

26.7

0.107

2.70

1000

305.0

1

27

161

73.0

1.315

33.4

0.126

3.20

500

152.5

1-1/4

35

218

98.9

1.660

42.2

0.133

3.40

250

76.2

1-1/2

41

263

119.3

1.900

48.3

0.138

3.50

250

76.2

1/2

3/4

EMI SHIELDING

Columbia-MBF RIGID is very effective in reducing electromagnetic field levels for encased power distribution circuits,

shielding computers and other sensitive electronic equipment

from the effects of electro-magnetic interference.

kg

Metric

The 3/4" taper NPT threads (ANSI B1.20.1) are full cut and

hot galvanized after cutting. Color-coded end-cap thread

protectors keep the threads clean, sharp and also provide

instant trade size recognition. Even trade sizes are colorcoded blue, 1/2 trade sizes black, and 1/4 trade sizes red.

1

Quantity In

Master Bundle

lb.

Trade Size

Columbia-MBF RIGID is hot-dipped galvanized inside

and out. It’s top-coated with a compatible organic layer

to protect against white rust and increase corrosion

resistance. It is impact and crush resistant for maximum

conductor protection.

Nominal

Wall

Thickness

2

53

350

158.7

2.375

60.3

0.146

3.70

200

61.0

2-1/2

63

559

253.5

2.875

73.0

0.193

4.90

100

30.5

3

78

727

329.7

3.500

88.9

0.205

5.20

100

30.5

3-1/2

91

880

399.1

4.000

101.6

0.215

5.50

100

30.5

4

103

1030

467.1

4.500

114.3

0.225

5.70

100

30.5

5

129

1400

634.9

5.563

141.3

0.245

6.20

10

3.05

6

155

1840

834.5

6.625

168.3

0.266

6.80

10

3.05

For more information only; not a spec requirement.

NOTE: Length = 10 ft. (3.05m) with a tolerance of +/- .25 in. (6.35mm).

* NEMA RN-3 Standard

Visit www.steelconduit.org/gemi.htm to obtain the GEMI

(Grounding and Electro-magnetic Interference) software

analysis program.

FULL CODES & STANDARDS COMPLIANCE

Columbia-MBF RIGID steel conduit is certified to CSA

C22.2 No. 45.Columbia-MBF RIGID is recognized as

an equipment bonding conductor by the Canadian

Electrical Code.

For more information, contact Columbia-MBF at

(866) 632-0180

or visit our website at www.columbiambf.ca

Installation of Rigid Metal Conduit shall be in

accordance with the Canadian Electrical Code and

certified to CSA C22.2 No. 45.

SPECIFICATION DATA

Rigid Steel Conduit shall be hot-dip galvanized and equal

to that supplied by Columbia-MBF, Inc. Threads shall be

hot galvanized after cutting. RIGID shall be certified by

CSA to C22.2 No. 45.

• Columbia-MBF, Inc.

6560 Northwest Drive, Mississauga, ON L4V 1P2 Canada Tele: 905-362-0180 Toll Free: 1-866-632-0180 Fax: 905-362-0186

Columbia-MBF ™ Electrical & Support Division

™

®

www.columbiambf.ca

• Columbia-MBF • Eastern Wire + Conduit • Power-Strut Metal & Fiberglass Framing • Cope Cable Tray • AFC Cable Systems™

™

™

The trademarks, logos, and service marks displayed on this brochure are owned or licensed by Tyco International Ltd., or its subsidiaries, affiliates, and others (collectively "Trademarks").

All Trademarks not owned by Tyco International, Ltd. are the property of their respective owners, and are used with permission or allowed under applicable laws.

© 2007-10 Tyco International, Ltd. all rights reserved. ATC-L-1749CA-1006