Got Zero? - Precision Rifle Workshop

advertisement

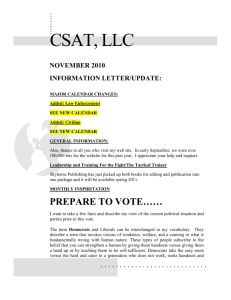

Got Zero? Sighting in a rifle can be a daunting task to the novice shooter. They are intimidated by the unexpected amount of expensive ammunition required to get the rounds on paper and get the rifle/scope locked into their desired point of impact. They waste money on laser bore sighters, paying gunsmiths to “boresight” prior to the rangetime and usually find results less than satisfactory. This task is further complicated by low quality scope bases, rings and scopes themselves. The lense ‘fogging” gets even worse with the tremendous amount of merchandising, outright false advertising for profits and scoundrel sales personnel. Go to the “shot show” every year and see booth after booth of well intentioned salesmen hocking “fogproof”, temperature proof, “crystal clear”, “top of the line” “illuminated reticle” “tactical” “super sniper” scopes for thousands of dollars that have junk turret adjustments. Our intent here is not to bash particular scope models or brands but to show you common issues with almost all optical scopes. An experienced shooter sighting in a higher end tactical rifle with a mil/mil setup on a quality scope usually requires two rounds. One to test, one to hit intended POI after the proper adjustments are made. The critical part being that when you turn the scope turrets, you get precision adjustments that match your reticle. In other words, when you adjust your scope settings 8.4 mils down and 2.2 mils right, the next bullet fired actually goes there. This requires match ammunition in a good rifle, a quality scope with quality turrets, solid bases and rings and a shooter practicing good marksmanship fundamentals. “Sighting in” or “Zeroing” a rifle means adjusting your scope or iron sights so that the Point of Impact matches the Point of Aim. This is a simple concept but prone to common errors. The mechanics for achieving this goal with a scope are: 1. Solid bases and rings attaching the properly mounted scope to the rifle. 2. A scope with quality turrets and turret adjustments that are calibrated. 3. A scope zero that “holds”. 4. A scope zero that is repeatable after making adjustments. Hunters typically “sight in” a rifle once a year to “check it” and carry on with their hunt. If the “zero” gets knocked off by travel hazards, dropping the gun or simply bumping the scope…..a two inch difference in POA/POI may cause some consternation such as “why did it hit there?” but usually doesn’t affect the hunt results. A hunter may not notice the discrepancy in his “zero” until the following year when he makes the annual trip to the 100 yard range to verify his sight again. We all have stories of missed shots and “adventures” of dropping the gun in the snow; falling down etc… later on we determine the fall caused our sights to get “knocked off”. If a hunter’s zero is off, they either miss their game completely or take the chance of wounding it. We have an entire gun cabinet full of rifles with cheap scopes and “zeros’ that are “close enough”. In the military, damaged or knocked off sights, whether glass or iron, typically aren’t noticed in the chaos of combat. Combat readiness for units usually calls for the occasional “zero check”. In the more elite units, precision sights become more prevalent and the training of operators is more extensive so a ‘zero” becomes more important. If an individual soldier or marine’s zero is off he puts his life and the welfare of his fellow operators in jeopardy. “Zeroing” becomes a more important factor. In police work, we’ve seen entire patrol rifle inventories “zeroed” by a range officer and then orders issued that “nobody messes with the sights”. We then would subject the rifles to constant daily abuse in a gun rack of a patrol car as its vibrated, banged, bumped and simply left collecting dust on a daily basis for years. Then in a moment of crisis, the officer grabs the rifle and hopes the zero is still intact. We’ve watched in amazement as supervisors issued patrol carbines to officers claiming they were ‘zeroed” and ready for issue. The supervisors basing their confidence on equally confident range officers, Neither one knowing what an individual rifle is capable of. This results in “ball park” zero’s for the rifles. Target or competition shooters typically understand zeroing and have very short lived comp careers if they don’t have a good zero on a given comp day. They understand more than most that you’re either ON or you’re OFF and losing. With precision rifles in police sniper operations, “Got Zero” is a basic tenet that must be followed strenuously. It’s very similar to target shooting “zeros’ with added issues of accountability, liability and the life/death of a hostage being on the line. The police sniper must constantly worry about keeping a “zero”. If a swat sniper’s gun gets bumped or knocked off even a couple MOA, a hostage’s life is in jeopardy. With that being said, maintaining a good zero with a precision rifle becomes something of an obsession. Police snipers typically train twice a month with 100-200 rounds. The training days include marksmanship, tactics, fieldcraft and observation skills. This allows golden opportunities to check zero and make sure the rifle/scope is ready to go on operations. Snipers keep data books to maintain legal records of what the ‘zero” on a particular rifle is through the course of its operational history. A good zero is the shooter’s responsibility. Keeping a good zero is dependent on good equipment, attention to maintenance and periodic status checks. Rings: Heavy duty, “double or triple” screw design is better than single screw. Your whole system and your zero should not fall apart if one screw comes loose. Ring lapping is important to keep a scope centered in the rings and to prevent damaging a scope tube. Ring lapping is also a “skipped” step on most setups when shooters get a new scope for a rifle and are impatient to get it to together. Bases: One piece is better than two piece. Integral bases are far better than ‘attached” or “quick detach” models. Make sure the attachment screws and nuts are properly torqued. Proper Torque: Probably the single most neglected factor in mounting scopes. “handtight” doesn’t cut it. Proper amount and proper sequence of torque is critical. An equal amount of pressure on all ring screws around your scope tube is the intent. Scopes: Quality varies wildly. We’ve seen 3000 dollar scopes that had bad turrets that didn’t work as advertised. We wish scope companies would spend as much time on turrets and accuracy of movement as they do on “fog proof” and “scope coatings”. Calibrated turret adjustments are mandatory. If the scope turret says two minutes of angle, it should move two minutes of angle. Shoot a box drill to verify your scope’s accuracy and repeatability. Shoot a “cross” drill to move your scopes elevation or windage adjustment’s through their full range to verify accuracy and return to zero. Does the turret have positive, audible clicks that move and feel like gear teeth or do they move like you are rotating a box full of soft mud. Are the markings easy to read and feel as you move the turrets through the scale? BDC’s, Custom turret etching or ballistic reticle marks: These are typically well intended attempts to match a rifle’s individual trajectory curve to a particular scope. Keep in mind the custom turrets need to be as well made and calibrated as the scopes internal adjustments. Some of the BDC’s out there are the equivalent of marking your scope caps with a sharpie. Custom built reticles are usually ball park accurate with an individual caliber because the scope company is trying to match some ballistic trajectory chart on the back of a box of ammunition. Rifles and ammunition: Use the same rifle with the same ammunition to eliminate these as the cause of your problems with zero. In other words don’t shoot one type of ammunition for zero one day then expect the gun to zero with something else at a later date. Properly torqued action screws on your rifle are however, critical to zero. Check this before you even start. A damaged rifle crown and a thousand other variables with rifles can affect zero also. We’ll save those for another article and another day. Reticles: Mildot, MOA or? Cheap scopes have cheap reticles. Cheap reticles aren’t calibrated and the visible ‘mildot to mildot” may not be a true calibrated milradian. Same with minute of angle reticles, an MOA should be an MOA in angular measurement. Break out a tape measure at your zero distance (typically 100 yards) and see if what you’re seeing is correct. A milradian at 100 yards shows 3.6 inches. A MOA reticle shows one minute as 1.047 inches at 100 yards. Remember that your scope power is typically at maximum to get a properly calibrated reticle view. Read your owner’s manual to verify. How Fragile is your Zero? Now we get to the crux of the issue. You would be unpleasantly surprised to see inside a scope and realize what mechanically keeps a scope “zeroed”. The original intent of a scope design is to keep zero after minor adjustments are made to set the initial zero. In other words, most scope turrets HOLD zero relatively well but what they don’t do is adapt well if you change it. If we take the typical off- the- shelf hunting scope and set it to zero, then make an 8moa up adjustment, then back down to the original zero, chances are, the scope will NOT return to zero. It will be “close” but typically not “exact”. One of our shooters put it in perspective, “take a child’s toy metal slinky, stretch it out 15 feet and when you let it go, it’s doubtful it will return to the exact same spot every time”. This is very similar to what happens when you “stretch” the typical scope’s adjustments to the outer extremes of the turret. You’ll occasionally see a shooter adjusting to this inherent “sloppiness” by doing the “scope shuffle” where you turn past your intended scope turret adjustment spot then back to “get the spring to settle”. Shooters will have some sort of other voodoo like “tapping the turret a couple times” as another solution. The spring we’re referring to is shown in red in the above diagrams. This single spring is responsible for “holding” your rifle’s zero. The spring puts tension on an internally floating erector tube inside the scope so that the turrets have tension to turn against. A turret can be well made but if the spring doesn’t hold consistent pressure, you have an inability to hold or adjust well for Zero. It won’t matter if your scope is filled with rare kryptonite blue gas or has titanium carbide diamond coatings, if this spring doesn’t hold you have a non-aerodynamic brick on top of your rifle. All the rest of the mechanics are window dressing. We’re not claiming here to know everything about scope mechanics or to have invented a “better way”. What we are, like the majority of readers, are Consumers. We deal with the same issues all shooters deal with. You sight in your rifle/scope. You haul it around, you bang it against things, you drop it and you pick it back up and hope it shoots okay. If the above spring has age issues, metal fatigue, outright failure, looseness or is poorly designed or manufactured, you have “zero” issues. This may not seem like a big deal to the average shooter. To the police sniper, it is at the essence of his very job. Here is a police sniper’s target from a recent PRW school. This is a box drill and this particular scope was a “tactical model” that cost the department $900 retail. This scope was expected (until this drill) to be the deployed scope on a rifle that is intended as a hostage saver. The department has since remedied the problem with a newer, better quality scope. This drills proper sequence is this: Shoot your zeroed first round into the orange diamond. Then make turret adjustments to move the next rounds into each of the black boxes even though you’re aiming at the same center orange diamond. After you have “walked” rounds in a “circle” in each of the black boxes, reset the turrets to come back to your original zero settings and shoot a final round into the orange diamond to verify “repeatability” of your zero. A correct target should have six rounds in it that looks very similar to a “five of dice”. In the above example, the first round went where it was intended, the left corner of the orange diamond. Then the shooter made adjustments to hit the black squares. At 100 yards, he dialed 1.5 minutes up and 1.5 minutes left. He fired the round and it went high on the left side. The shooter dialed 3 minutes down and the next shot went somewhat correctly into the lower left box. He then dialed 3 minutes right and instead of hitting the black box, the round went into the right corner of the orange diamond. He dialed 3 minutes up to hit the last black box and his round went high and right. He now dials 1.5 minutes down and 1.5 minutes left to return his turrets to the original “zero” setting and his final round went up high between his “black box shots”. The scope not only failed to track correctly and make proper dope adjustments, it also did not return to zero. We have seen this time and time again with scope setups on rifles where shooters honestly believe they have a “zeroed rifle”. We recommend our active duty snipers actually run this box drill at least once a year just to make sure their scopes are performing correctly. It would not be a bad idea for any shooter to do with his equipment. A “cross” drill is very similar. Take a “long” vertical piece of paper as a target. Bottom out your scope by dialing the elevation turret all the way down to mechanical zero. Fire one round at the bottom of your paper. You may have to adjust your paper or rifle to arrange this. Now dial up and fire one round every five minutes of angle. Keep dialing and shooting until you reach the TOP of your scope elevation adjustments. You can shoot a lot of rounds this way so we’d recommend this only when you’re having “issues” with a particular scope and do it at 10 yards so you don’t need a 25 feet tall piece of paper. You will have a vivid picture of the accuracy of your elevation turrets. You should have a nice stitching of rounds every five minutes from top to bottom of your scope. (Remember at 10 yards, five minutes of angle is 5/10ths of an inch, ½ an inch) Just like the box drill, reset everything to zero and shoot a final round just to see if your zero repeats, as it is supposed to after making all the various up and down adjustments. For your windage, shooters typically do not dial “as much” or turn their turrets as much. Scope companies know this and most scopes do not have as much total adjustment. You can check the windage accuracy and adjustments in the same manner as the elevation. Keep in mind, when you “max” out your turrets, you are also putting maximum stress on the “spring” and the cheaper scopes can be permanently damaged if you leave the turrets turned to their extreme settings. Cheaper scopes have cheaper springs. Remember your zero is dependent on whether ONE spring holds tension. Remember also that the turret markings are the exact opposite of what the tension is on the spring. If you’re dialed all the way UP on our elevation knob you are putting the MOST tension DOWN on the spring. With the windage, the knob needs to be dialed all the way to the right to put the least amount of tension on the spring. This can also depend on the scope model if the windage knob is on the opposite side. Think about these concepts when you put a scope away for long term storage. They won’t hold or maintain zero over extended times in storage. Sorry, we don’t have a lot of solutions. What we do have is advice. Treat your rifle’s zero like you’re carrying around an infant child in your arms. You must protect it, cherish it, check on it constantly and never trust it alone. If your only worry is missing a paper target or steel gong, maybe you can relax a bit. If you are in a job where your “zero’ could save a life or protect your brothers in harm’s way, check it ALL the time. The life you save may be your own. Zero is not all about fancy expensive scopes. Zero is about hitting EXACTLY what you’re aiming at. Something all shooters are typically interested in. Got Zero? Neal PrecisionRifleWorkshop.com 1-877-860-9475 admin@precisionrifleworkshop.com