A Method for Predicting the Expected Life of Bus Capacitors

advertisement

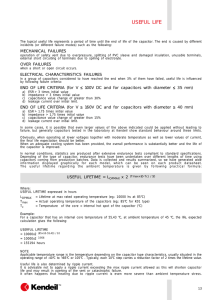

IEEE Industry Applications Sociaty Annual Meeting New Orleans, Louisiana, October 5-9,1997 A Method for Predicting the Expected Life of Bus Capacitors Michael L. Gasperi Advanced Technology Labs Rockwell Automation 1201 South Second St., Milwaukee, WI 53204 Email: mlgasperi @mke6.ra.rockwell. Phone: (41 4) 382-2508 Fax: (414) 382-3500 the expected life of Abstract - Predicting motor drive bus capacitors is complicated by several factors: the equivalent series resistance of aluminum electrolytic capacitors is frequency and temperature sensitive, the ripple current is a composite waveform, and the capacitor expected life is very sensitive to operating temperature. This paper describes a method that addresses all these factors by developing separate models for capacitor equivalent series resistance, motor heat transfer conditions, and drive circuitry, capacitor life. INTRODUCTION Voltage source inverter motor drives rectify the AC line and use aluminum electrolytic capacitors to create a filtered DC bus. These capacitors must endure relatively high ripple currents which lead to self heating. Self heating in addition to high ambient operating temperature can make the capacitors the weak link in drive expected life. Capacitor manufactures publish a rated ripple current, but it is motor drive operating nowhere near typical conditions or motor drive design lifetimes. i Capacitor Equivalent Circuit 5? Drive Model Power Dissipation -turfLife Model Y Expected Life Fig. 1. Method for Predicting Expected Life Fig. 1 illustrates the design method presented in this paper. The first step is to develop a more accurate model of equivalent series resistance ESR than a com simple fixed series resistance. The next step is to run the capacitor model in a circuit simulation to get the expected power dissipation. Power dissipation becomes temperature rise by accounting for the heat and the expected life is transfer conditions, computed from the resulting capacitor temperature. EQUIVALENT SERIES RESISTANCE MODEL The normal method for modeling capacitors utilizes a series combination of an ideal capacitor, a pure resistor, and optionally, an ideal inductor [8 and 9]. The resistor in the model is known as the equivalent Three major sources series resistance or ESR. contribute to the value of ESR in aluminum electrolytic capacitors: the oxide dielectric produces a frequency sensitive resistance, the electrolyte creates a temperature sensitive resistance, and the foil, tabs, and terminals represent an additional small source of relatively constant resistance[5]. The effect of frequency on dielectric resistance appears in the ripple current multipliers provided by capacitor manufacturers [11 ]. The effect is caused by energy losses in the alignment of dipoles in the dielectric and variations in the time it takes for the dipoles to become orientated [12]. It becomes more significant for higher rated voltage capacitors because their oxide layer is thicker. For applications with single frequency ripple current, the ESR can be simply adjusted by using a multiplier. Motor drives create a ripple current spectrum too complex for simple multipliers. Fig. 2 illustrates an Resistance RO improved capacitor model [3]. combines the resistance of foil, tabs, and terminals RI accounts for electrolyte. A parallel while combination of Rp and Cp models the dielectric resistance. Equation (1) describes the complex impedance of the capacitor, but ripple current heating occurs only in the real part of this impedance (2 and 3). 07803-4070-1/97/$10.00 (c) 1997 IEEE 1 T 100% c’ & 7’2“+ 90% o c1 I Fig. 2. Aluminum Electrolytic Capacitor ,,, ,,, ,,, Model 60% ~ Modeling with more series-parallel resistor capacitor pairs achieves a tighter fit to both ESR and capacitance behavior [1O and 14]. However, one pair appears to be sufficient for estimating heat generation. z cap 1 +R1+RO– = -J-+j2mf Cz j — 27Cfcl 1) H2 Where: z cap Complex Impedance of Capacitor Ro Resistance of Foil, Tabs, & Terminals RI Resistance Rz c, Dielectric Loss Resistance (Q) Terminal Capacitance (F) Dielectric Loss Capacitance (F) Frequency (Hz) C* f of Electrolyte (Q) (Q) ‘ ,,, ,,, ,,, ,,, !l, , 1000 Frequency (Hz) ,,, , ,,, , ,,, , ,,, , 10000 Fig. 3, Effect of Frequency on ESR Actual at 50°C and Fit using Equation 3 Manufacturers often provide generic curves showing the effect of temperature on ESR for their products. These curves can be used with the ripple current multipliers to obtain an estimate of the values for the However, a more components in the model. accurate alternative is to experimentally measure the ESR and capacitance over a range of temperatures and frequencies and use least squares to fit the values to the data. Fig. 3 and 4 illustrate the good fit achieved by this process and Table 1 shows the values for an actual capacitor 180% (2) .,, 100 200% ESR = Real(ZC.P) ,,, , ,,, , ,,, , ~ 1 I I 50 75 (“C) \ (j09’o o k-l R2 Real(ZC.P ) = +R1+RO (3) 1 + (2z f)2C; R; a 140’% M U 120’%0 ,* g Increasing temperature causes a decrease in ESR due to the increased conductivity of electrolyte RI. High rated voltage devices have more sensitivity to temperature than low rated voltage devices because they use lower conductivity electroiytes[l ]. Equation (4) captures the temperature sensitivity normalized tO the base reSktiN7Ce at room tfHTIpfMtUtE RI base. It is common for the elevated temperature ESR to be half the room temperature value. R, = R, ~a,e #,.as.- Tcor,)/E (4) Where: RI b,s. T core Tb,~, RI at Base Temperature Tb.s, (Q) Core Temperature ~K) Base Measurement Temp =23’C=300’K E Temperature 100% 80% 60% 25 Temperature Fig. 4. Effect of Temperature on ESR Actual at 120Hz and fit using Equation 4 Table 1. Values for 400V Rated Voltage 470uF Snap-in Capacitor ~ Series Resistor RO 0.035 Q Series Resistor Rlba~. @ 23°C Sensitivity Factor (“K-’) 100 Sensitivity Dielectric Factor E Loss Resistor Rz Series Capacitor Cl Dielectric Loss Capacitor 07803-4070-1/97/$10.00 (c) 1997 IEEE Cz 0.12 Q p, OK-l 0.038 Q 470 pF 11,000 pF MOTOR DRIVE MODEL Ripple current heating is estimated by running the capacitor model in a circuit simulation tool like PSpice [6]. Fig. 5 shows the schematic of a simple AC motor drive converter and inverter used to test Two Fig. 2 style capacitor the capacitor model. models are used to simulate the series connection needed to achieve a higher bus voltage than the available rated voltage of the capacitors. Three phase AC line impedance (5) has a significant effect on the 360Hz component of the current ripple and must be included. The PWM of the inverter coupled with the motor impedance create the high frequency components of ripple current. -15 I 1 o 0.005 m -L” , . 0.01 (S) . . 0.015 0.02 Fig. 6. Ripple Current 11in Drive Simulation : :,:;;;;:, ; ; ,,, ,,, I 6 Recti5er - 1 Time 7, % , 5 :4 . AC ?I Motor ~ Line Inductance I -r I-15!_l , -1 -12 t 11 Fig. 5. Motor Drive Simulation 100 1000 Frequency (Hz) Model 10000 Fig. 7. Ripple Current Spectrum i’line’% = ‘iL1”M’(2Z ’60) PF V~~s ,00% Where Qd 1, I* Where Zhne L iRMs f6rJ V~~s PF Line Impedance YO Line Inductance (H) RMS Rated Current (A) Line Frequency = 60 Hz RMS Rated Voltage (V) Power Factor = 0.95 (6) Q~ =1; RO +I;R1 +1; Rz (5) Total Power Dissipation (W) RMS Ripple Through ROand RI (A) RMS Current Through RZ (A) h~ 4 2 Two simulation probes are used to log the current in Ro, RI and R2 during the run. Fig. 6 shows the waveform for the ripple current 11in RO and RI. The Fig. 7 spectrum of the current shows practically nothing below 360Hz and many components at the 4 Fig. 8 shows the kHz PWM carrier and above. smaller current in Rp which is primarily 360Hz and lacks high frequency content. At the end of the simulation run the RMS value of the current in each resistor is used to calculate the energy loss. Adding the resistor energy loss values gives the estimated ripple current heating for each capacitor (6). so g -2 & -4 -6 -8 -lo o 0.005 0.01 Time (s) 0.015 0.02 Fig, 8. Dielectric Loss Current 1Pin Drive Simulation As capacitors age their RI ESR increases, and as Fortunately, they heat up their RI ESR decreases. 07803-4070-1/97/$10.00 (c) 1997 IEEE capacitance dominates the impedance in the drive circuit so the change in ESR has little effect on the magnitude of the ripple current. Fig. 9 shows a range of values for ESR and the minimal resulting change in ripple current. 8 0.9. Convection is modeled with (9) with the heat transfer coefficient for natural convection modeled by (1 O) [13]. Fig. 12 shows the heat transfer from the two modes is nearly equal for appropriate range of temperature rise. A more experimentallv , derived equation for screw terminal “style capacitors is provided in [4]. I I ’11 — ’12 3.5 ;; ,,, ,,, ,,!mlr ,,, ,,, ,, ,,, ,,, ,,, ,, ,,, ,,, ,, ,, ,,, ,,, , ,,, ,,, ,,, ,,, , ,,, ,,, ,,, ; I 1 :; 0.5 ; 0 : ,,, ,,, ,,, 4 0.04 RO +Rl 0.02 Fig. 9. insensitivity 0.06 (Ohm) ,,, 0.08 0.1% of 11and IZ to ESR Although the capacitor ESR has little effect on ripple current, the AC line impedance has a dramatic effect. Figs. 10 and 11 show the consequence of line impedance on the current and the resulting The eventual result of line power dissipation. impedance on life can be calculated after the power dissipation is related to temperature rise through a heat transfer model. ..1--,, ,,n r,, 1 . . . ,,,,, ..... ‘:%::::: ,, ,,, ,, ,,, ,,, ,, ,,, :h& ,,, ,, ,,, ,,, ,,, . . ,,, 0!” 0.1% . Where T~ T case AT ,1. & F ,, . . I ,,, ,,, 1.0% Line Impedance Fig. 10. Effect of Line Impedance HEAT TRANSFER ,, on Current ,,, ,,, , ,’,,, ,,, ,,, ,, ,, 10.0% on Power (7) (°K) S F(T$,~, -T: Heat dissipation from radiation Stephan-Boltzmann constant ) (8) (W) 10-8 W/m* “K4 Emissivity, Assumed = 0.9 Shape Factor = O to 1 QCO. = h SAT Where Q con h s (9) Heat dissipation from convection (W) Heat Transfer Coefficient W/m* “C Surface Area (m2) MODEL Heat transfer conditions are needed to convert the energy loss to a temperature rise (7). Capacitor banks are primarily cooled by a combination of natural air convection and radiation. Equation (8) models radiation where the emissivity of the capacitors are assumed to be close to black body at ,,, , ,., . ,,, ,,11. , Ambient Air Temperature Case Temperature (“K) Temperature Rise (“C) I 10.0% ,,, ,, ,,, ;:::::: ,,, ,,, , AT = TCa~.- T~ = 5.669x .,, ,, ,,, ,, ,,, ;;;;;;; 1.0% Line Impedance Q,,~ = os , ,,, Fig. 11. Effect of Line Impedance Dissipation Where Qrad G 1,, .!. ,.. , . ,,, h= 1.32 (AT/2r)”4 S=27T Where z Capacitor (lo) (rz+r2) (11) Height (m) The heat transfer equations provide a wav of estimating the surface temperature of the capacitor, 07803-4070-1/97/$10.00 (c) 1997 IEEE J but the core temperature is more important in predicting the life of the capacitor. Equation (12) estimates the core temperature rise by assuming the core rise is a constant factor greater than the surface rise. If the internal construction of the capacitor is known, then a more accurate heat transfer model can be built and the core temperature more accurately accounted. TCO,,= T~ + a AT (12) Where Relative Temperature (x Rise Factor = 1.5 LIFE MODEL The primary wear-out mechanism for aluminum electrolytic capacitors is vaporization of electrolyte and its loss through the end seal [7]. As the volume of electrolyte decreases the equivalent series resistance ESR of the capacitor increases as modeled with (13). Eventually, the parameters drift out of specification and the capacitor is considered to have failed. For applications with ripple current the increase of ESR leads to increased internal heating that accelerates the wear-out process. 2,5 ESR/ESRO = (VO/V~ El Free Convection 2 Where ESR ESRO v Vo ESRadiation s :1.5 .: a .:1 .2 n 0.5 0 O 5 10 15 20 Delta T (“C) Fig. 12. Heat Dissipation 25 30 @ TA = 50 “C Because the ESR drops with increasing temperature due to increased conductivity of electrolyte, an aluminum electrolytic capacitor actually dissipates less power with the same ripple current at higher temperatures. Fig. 13 shows the cross over point where the actual dissipation equals the heat transfer capability. For this example the equilibrium temperature rise is 15 “C. Equivalent Series Resistance @ 20nC Initial ESR (Q) Volume of Electrolyte (Units) Initial Volume of Electrolyte (Units) (13) (Q) The life model presumes that the rate of electrolyte loss is directly proportional to the vapor pressure of the electrolyte [2]. A constant k in (14) is used to characterize the quality of the end seal. Equation (15) relates the core temperature to the vapor pressure of the electrolyte that is primarily Ethylene Glycol. Numerical integration can be used with (13, 14, and 15) until the capacitor is at its end of life. dV/dt = k P Where t k P (14) Time (h) Leak Rate Constant (Units/mmHg/h) Vapor Pressure of Electrolyte (mmHg) A -—+6 Ps 2.5 e [1‘COW (15) Where For Ethylene Glycol: A = 7060 and B =21 .63 2 0,5 0 0 5 10 15 20 Delta T (“C) Fig. 13, Temperature 25 30 Fig. 14 shows the estimated effect of line impedance on expected life. It was created by varying the line inductance in the drive simulation, noting the resulting values of II and 12, calculating the power dissipation, temperature rise, and estimating the life. It shows the significant reduction in expected life that can accompany applying a motor drive to low impedance sources. Rise @ TA = 50 ‘C 07803-4070-1/97/$10.00 (c) 1997 IEEE 8. 1000% 9. 10. ~ . . . .... . . . ....*.....,s, A. . . . . . . . . . L.9. I.LIA . . . . . . ,,. . . . . . . . . . . . . . ff,~ ,,1 1% 0.1% . . k.+ a.a. . . ..h. . . . . . . . . . . . ..4.....- 1 . . . . . . . ,,, . . . . . . . . .. k.- . . . ,,, ..,1 11. kbkw . ,,, . . . ,.f~,~ ,!.1 : 1.0% 10.0% Line Impedance Fig. 14. Effect of Line Impedance Life 12. 13. on Expected SUMMARY 14. Prymak, J. D., “SPICE Modeling of Capacitors,” CARTS 95, March 1995, pp. 39-46. Schnabel, W., “Aluminum Electrolytic Capacitors for Power Electronics,” CARTS-Europe 88, October, 1988, pp. 85-92. Scholte, J. W. A. and van Geel, W. Ch., “Impedances of the Electrolytical Rectifier,” Philips Research Reports 8, 1953, pp. 47-72. Electrolytic Aluminum United Chemi-Con, Capacitors, Catalog H7, Rosemont, IL, 1995, p265. Young, L., Anodic Oxide Films, Academic Press, New York, NY, 1961, p158. Holman, J. P., F/eat Transfer, McGraw-Hill Book Company, New York, NY, 1973, P253. of Network Synthesis to Tillo, J., “Application Inductor and Capacitor Modeling,” CARTS-97, Institute, Inc., Technology Components Huntsville, AL, March, 1997, p76-87. A method for estimating bus capacitor expected life has been presented. The method utilizes separate models for capacitor ESR, motor drive circuitry, heat transfer conditions, and life prediction. The method was used to show the significant effect of AC line impedance on capacitor expected life. REFERENCES P. M., Electrolytic Capacitors, The 1. Deeley, Cornell-Dubilier Electric Corp., South Plainfield, NJ, 1938. Model for M. L., “Life Prediction 2. Gasperi, Aluminum Electrolytic Capacitors,” 31 ‘t Annual Meeting of the IEEE4AS, Vol. 4., October, 1996, pp. 1347-1351. N., Sladky, R., “A 3. Gasperi, M. L., Gollhardt, Model for Equivalent Series Resistance in Aluminum Electrolytic Capacitors,” CARTS 97, Inc., Institute, Components Technology Huntsville, AL, March, 1997, p71 -75. and Ripple 4. Hayatee, F. G., “Heat Dissipation Current Rating in Electrolytic Capacitors,” Electrocomponent Science and Technology, Vol. 2, 1975, pp. 109-114 F, G., “The Equivalent Series 5. Hayatee, Resistance in Electrolytic Capacitors,” Electrocomponent Science and Technology, 1975, Vol. 2, pp. 67-72. Corporation, Circuit ArM/ysis User’s 6. MicroSim Guide, Irvine, CA, April 1995 7. Moynihan, John D., Theory, Design and E/ectro/ytic Capacitors, Application of Inc., Institute Technology Components Huntsville, AL, 1982. 07803-4070-1/97/$10.00 (c) 1997 IEEE