123

a r l o n ®

ARLON® 1000

THERMOPLASTICS FOR HYGIENIC FLUID HANDLING

AND PHARMACEUTICAL APPLICATIONS

Greene, Tweed’s Arlon® 1000, a tough, high-temperature, semi-

1 0 0 0

crystalline thermoplastic, offers a unique combination of mechanical,

thermal and chemical properties. Arlon 1000 features superior

compressive strength and minimum creep, as well as broad chemical

resistance. Arlon is an excellent choice for applications such as

\

valve seats and bushings requiring greater abrasion resistance and

Chemical Resistance

Arlon 1000 is a crystalline polymer, so it provides excellent resist-

Process and Design

ance to chemical attack (its only known solvent is concentrated

sulfuric acid). Arlon works well in most environments (with the

and aliphatic and aromatic hydrocarbons. Unlike many competitive

thermoplastics, Arlon will not hydrolyze and is recommended for

use in steam or other high-temperature aqueous environments.

is limited by the inherent properties of the basic polymer, crystalline

materials, such as Arlon, are extremely processing sensitive. Greene,

Tweed exercises tight control over preconditioning, molding and

post-molding operations that influence the level and type of crys-

d a t a

exception of strong oxidizers) and is compatible with acids, bases

While the ultimate performance of any thermoplastic component

p r o d u c t

lower wear and better fatigue properties than other thermoplastics.

tallinity of the resulting material. Additionally, Greene, Tweed

FDA Compliancy, U.S. FDA Regulation 21 CFR 177.2415

Arlon 1000 generates little to no detectable extractable, making it

custom designs take full advantage of Arlon’s strengths.

Engineering Expertise

ideal for use in food, pharmaceutical and other hygienic fluid

handling applications where microcontamination cannot be tolerated.

For complete and uncompromising solutions to pharmaceutical or

hygienic fluid handling applications, Greene, Tweed offers a range

Radiation Resistance

of product, documentation of physicochemical properties, in-house

design capabilities, dependable technical support and global part-

thermoplastics, Arlon does not suffer the same effects. Arlon offers

excellent resistance to embrittlement when exposed to gamma

radiation and outperforms polystyrene, a common radiationresistant material. Arlon maintains this resistance in both acid

and alkali media.

w w w. g t w e e d . c o m

nering necessary for continuous and flawless performance.

© 2008, Greene, Tweed all rights reserved

All trademarks are property of their respective owners.

06/08-GT DS-US-PP-039

While radiation resistance is a common weakness of PTFE and other

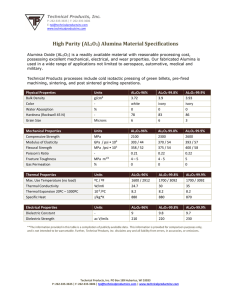

TYPICAL PROPERTIES

ASTM

Method

Typical Value

Color

Tan

Specific Gravity

D792

1.30

Hardness, Shore D, Points

D2240

88

Rockwell M Hardness

D785

104

Coefficient of Dynamic Friction,

PV=12,600 psi-ft./min.

G77

0.29

Compressive Strength @ Break, psi (MPa)

D695

19,000 (131)

Deformation Under Load, %

Elongation @ Break, %

D621

D638

0.09

35

Flexural 0.5% Secant Modulus, psi (MPa)

Flexural Strength, psi (MPa)

D790

600,000 (4,140)

D790

25,300 (174)

Shear Strength, Axial, psi (MPa)

Shear Strength, Transverse, psi (MPa)

D732

12,400 (85.5)

D732

D638

12,400 (85.5)

615,000 (4,240)

D638

14,000 (96)

Tensile Yield Strength, psi (MPa)

D638

15,600 (108)

Wear Factor, 10-10in.3-min./(lb.-ft.-hr.)

G77

52

Coefficient of Thermal Expansion

< 300°F (150°C), 10-6 in./(in°F)

E228

26

Coefficient of Thermal Expansion

> 300°F (50°C), 10-6 in./(in°F)

E228

75

Heat Deflection Temperature

@ 264 psi (1.8 MPa), °F (°C)

D648

350 (180)

Mechanical

Tensile 0.5% Secant Modulus, psi (MPa)

Tensile Strength @ Break, psi (MPa)

Thermal

© 2008, Greene, Tweed all rights reserved

All trademarks are property of their respective owners.

06/08-GT DS-US-PP-039

a r l o n ®

1 0 0 0

\

p r o d u c t

d a t a

Physical Properties

123

w w w. g t w e e d . c o m

Contact Us

Greene, Tweed

PetroChem & Power

Houston, TX, USA

Tel: +1.281.821.2094

Tel: +1.800.820.9005

Fax: +1.281.821.2696

Statements and recommendations in this publication are based

on our experience and knowledge of typical applications of this

product and shall not constitute a guarantee of performance nor

modify or alter our standard warranty applicable to such products.