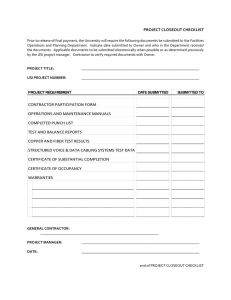

Prefunctional Checklist

advertisement