PRE-FUNCTIONAL CHECKLIST AND FUNCTIONAL TEST FOR

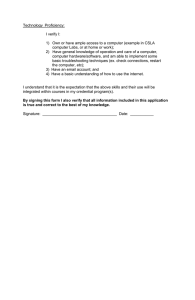

advertisement