Sensus: Products

advertisement

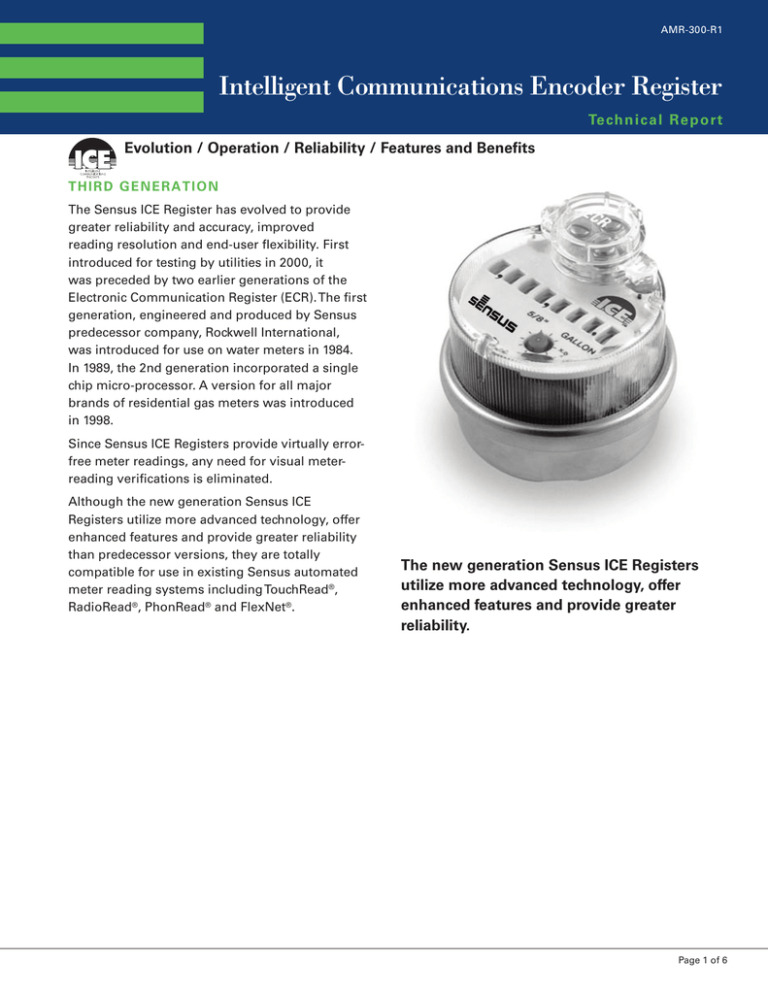

AMR-300-R1 Intelligent Communications Encoder Register Technical Report Evolution / Operation / Reliability / Features and Benefits THIRD GENER A T I O N The Sensus ICE Register has evolved to provide greater reliability and accuracy, improved reading resolution and end-user flexibility. First introduced for testing by utilities in 2000, it was preceded by two earlier generations of the Electronic Communication Register (ECR). The first generation, engineered and produced by Sensus predecessor company, Rockwell International, was introduced for use on water meters in 1984. In 1989, the 2nd generation incorporated a single chip micro-processor. A version for all major brands of residential gas meters was introduced in 1998. Since Sensus ICE Registers provide virtually errorfree meter readings, any need for visual meterreading verifications is eliminated. Although the new generation Sensus ICE Registers utilize more advanced technology, offer enhanced features and provide greater reliability than predecessor versions, they are totally compatible for use in existing Sensus automated meter reading systems including TouchRead®, RadioRead®, PhonRead® and FlexNet®. The new generation Sensus ICE Registers utilize more advanced technology, offer enhanced features and provide greater reliability. Page 1 of 6 AMR-300-R1 TRADITIONA L V I S U A L R E A D I N G / M ANUAL REC O R D I N G A reading is obtained by visually reading a register’s numerical indicators, i. e., odometer-type wheels on more modern registers (Figure 1); or circular dials on older water meters and, until very recently, gas and electric meters (Figure 2). The meter reader either writes the numbers into a route book, or keys the numbers into an electronic route book, which has evolved into storing the information in a solid-state memory. Both methods are subject to human errors in reading and recording the data. When the route is completed, the readings are taken to the utility office where they are used to calculate customers bills. With paper route books, the data again must be manually-keyboarded, usually by a billing clerk, into the billing computer, lending a second opportunity for human error. The visual reading / manual recording method is the most expensive and least efficient method of collecting and processing meter readings. Figure 1 Figure 3 readout module to advance the digits on the module (Figure 3). Although pulse generator-remotes provided a good solution for overcoming the problems cited previously, the remote modules often provided readings different from those on the meter register, due to electrical contact and mechanical problems, variations in pulse integrity and inadequate maintenance practices. The unreliability of the technology led most state regulatory agencies to mandate that a reading of the meter register be conducted each one or two years to insure that the register and remote module readings were the same and to synchronize them if they were not. E A R L Y 1 9 6 0 ’ S – E L E C T R O N I C E NCODED P U L S E - G E N E R A T I N G T E C H N O L OGY Figure 2 THE HISTORY A N D E V O L U T I O N O F M ETER READ I N G M E T H O D S Understanding the history and evolution of meter reading methods helps to identify the advantages of the Sensus ICE Register. EARLY 1960’ S – P U L S E - G E N E R A T I N G REGISTERS F O R R E M O T E R E A D I N G Remote reading equipment, introduced in the 1960’s, provided for installing a digital counter showing the meter’s reading at a location away from a meter, usually on an outside wall of the building in which the meter was installed. The method was faster, more efficient and economical as it greatly overcame the need to enter the building and get to the meter to read it, as well as the problem of lock-outs resulting from working people not being at home. It also served to help cut ever-spiraling labor costs. Pulse-generating registers electro-mechanically produce an electrical pulse for each unit of measurement a register is designed to display, i.e. : 1,000 gallons; 100 cubic feet or 1m3. The electrical pulse is transmitted over a two-conductor cable to the remote Some improvement on early pulse-generator technology came about with the introduction of registers that replaced the electro-mechanical pulsegenerating mechanisms with switch-closure devices. In addition to being more reliable, they provided for obtaining more precise readings and depictions of usage in much smaller units, i. e. :1 gallon;10 gallon; 1 cubic foot; et cetera. Although such registers often were referred to as “electronicallyencoded” by their manufacturers, the reference meant only that each electric switch closing generates an electric pulse that is counted and retained by a battery-powered, electronic memory circuit, either at the register or at a remote location (Figure 4). When the memory circuit is interrogated by an electronic meter reading device, such as a handheld interrogator / recorder unit or AMR system telemetry interface unit, the billing unit pulse count is converted into an electronically-encoded signal and relayed to the unit. The method requires an intermediate link, a memory circuit, to get the reading data from the register to the data-recording device. Because it is still pulse-based, the method is not fault-proof and can be subject to inaccurate readings and, thereby, incorrect billings Early 1960’s Mid 1960’s 1970 1984 Visual reading / manual recording Pulse-generating registers for remote reading and electronic encoded pulse- generating technology Absolute-encoded register technology Sensus TTR Sensus ECR Page 2 of 6 AMR-300-R1 OMNI-204-R2 identification number contained therein, produced the data as an encoded digital signal, and automatically transferred the data to the solid-state memory of a handheld interrogator /recorder or other solid-state memory. One of the benefits of encoder registers is that industrystandard interface conventions such as ASCII. This makes them suitable for use in more advanced AMR systems. Therefore, encoder registers provide the best option for compatibility with future information transfer technologies. 1 9 8 5 – T H E T O U C H R E A D ® S Y S T EM FOR READING THE ECR-II Figure 4 to a utility ’s customers. Again, costly periodic visual readings must be taken and reconciled with those received by the interrogator / recorder unit. This technology is still being used by some prominent manufacturers. M ID 1960’S – A B S O L U T E - E N C O D E D REGISTER TE C H N O L O G Y Absolute-encoded registers were developed in the mid-1960’s to provide a more reliable and trouble-free meter-reading system than pulse-based technology could deliver. The word “absolute” was added to describe registers that truly did use electronic encoding technology. 1970 – SENSU S E N C O D E D R E G I S T E R DEVELOPMEN T The first encoder register remote reading system, TeleTape Remote (TTR), was introduced in 1970 by Sensus predecessor-company, Rockwell International. The TTR System provided a low-cost, reliable method of transmitting reading data based on the position of a register’s wheel positions, to a remote module from which the data was collected using a portable cassette tape recorder. In 1985, Sensus offered the first generation TouchRead® remote reading system (Figure 6). This system was the first to use single chip microprocessor technology and an entirely solid-state data collection device for reading meters remotely. When powered by the TouchRead System’s Solid State Interrogator, the microprocessor scans the registers encoded wheels and the factory-set register identification number. The register outputs an encoded digital data signal through a patented, inductive coupling, half in the TouchPad and the other half in the tip of the reading gun, into a portable interrogator where it their electronic output signal can be formatted to is stored for later retrieval. The technology provides for obtaining readings without conventional, troublesome “plug-in” electrical connectors used in other remote reading systems. Encoder-type registers can be accessed for reading through a remotely-mounted interface module referred to as a TouchPad®. To obtain a reading, the tip of a reading “gun,” which is wired to a battery-powered, handheld interrogation unit, is placed on the TouchPad. With the touch of a button on the gun, power is transmitted to the register enabling the electronics in the register to determine the physical positions of the register’s odometer wheels. The data is passed back through the TouchPad into the reading gun and recorded in one of two ways. (Figure 5). TTR System registers did not provide a data output protocol compatible with automatic data transmission via telephony or radio-based methods. 1984 – INTRO D U C T I O N O F T H E S E N S U S ELECTRONIC C O M M U N I C A T I O N S REGISTER (E C R ) In 1984, after 14 years of successful applications of the Sensus Encoded Register, an advanced version was introduced and designated the Electronic Communications Register, or ECR. The advancement was in the addition of a singlechip microprocessor. The microprocessor scanned the register’s wheel positions, read a factory-set Figure 5 1985 1989 2000 and Beyond Sensus ECR TouchRead® System for reading the ECR II ECR II with integrated circuit chip and AMR Advanced Sensus ICE Register Revolution Page 3 of 6 AMR-300-R1 Data is displayed on the reading gun’s screen and visually read by the meter reader, who then inputs the data via a keyboard on the handheld recorder. The process requires the manual transfer of the data, which lends itself to errors caused by visual misreadings or incorrect key punching. When the tip of the reading gun is placed on the TouchPad and activated, the reading data is automatically transferred to and stored in the interrogator / recorder. With present technology, the reading gun can transmit the reading data via a low-power radio transmission instead of via a cable. (Figures 5 and 6) Figure 6 In more advanced AMR systems, one or more encoded registers can be wired to an electronic interface unit that transmits the readings data via a short-range radio transmission or by telephony to a data collector. 1 9 8 9 – A U T O M A T I C M E T E R R E A DING (AMR) APPLICATIONS 1989 – FURTH E R D E V E L O P M E N T O F T H E ECR WITH AN I N T E G R A T E D C I R C U I T CHIP – THE E C R - I I In 1989, the ECR was upgraded again into the ECR-II version. The primary new component in the ECR-II was a custom, application-specific, integrated circuit chip (ASIC), which provided the distinct benefit of operating at a much lower power level. It incorporated advanced technological components and state-of-theart manufacturing processes that provided for better quality control. Process improvements for the ECR-II included the incorporation of a patented moisture barrier inside the polycarbonate register cover. The feature provided for confidence in using ECR-II registers in outdoor, oftenflooded meter pits. The ECR-II register was designed with a pathway for use in Automatic Meter Reading systems such as the Sensus RadioRead and PhonRead AMR systems (Figure 7). For AMR applications, the register has three screw terminals incorporated in its cover, used for connecting the register to a telemetry module. The three terminals provide for power in, signal out and a ground connection. The output signal is in the industry standard ASCII code, thereby making it compatible with AMR interface devices presently provided by major manufacturers, and highly-likely to be compatible with future technologies. The technological advances ushered in with the ECR-II afforded customers options to build robust, comprehensive communications systems around the register. Figure 7 Page 4 of 6 AMR-300-R1 OMNI-204-R2 THE REVOLU T I O N O F M E T E R R E A D I N G M ETHODS Introduced for field testing in 2000, the advanced Sensus ICE Register provides features and benefits that are not available in any other meter register. Despite its advanced design, it is totally backwardcompatible with predecessor ECR and ECR-II-based systems, making it the most logical choice for each and every AMR and electronic communication application. It is also fully-compliant with ANSI/AWWA Encoder Standard C707-82 (R-92). Its wheel position sensing technology is described in U. S. Patent #5, 796, 250. A visible indication of its distinctiveness is on the register face. Instead of the traditional six odometer-type wheels and a sweep hand, there are eight odometer wheels for higher resolution and a combination testing pointer and leak detector (Figure 8). Figure 9 with that coil. The resonation value is detected and processed to determine the angular position of each wheel, and is converted into a numerical value that is the basis for the reading. A B S O L U T E E N C O D E R W H E E L P OSITION SENSING The Sensus ICE Register continues the proven and reliable “absolute encoder” technology of its predecessors. A mechanical, gear-driven odometer assembly is used for such traditional visual-reading functions as verification. ASCII-BASED PROTOCOL FOR C O M P A T I B I L I T Y W I T H O T H E R B RANDS OF READERS Figure 8 LOW-FRICTIO N , N O N - C O N T A C T WHEEL POSIT I O N S E N S I N G P R O V I D E S GREATER RE L I A B I L I T Y The ICE Register utilizes “magnetic-field positionsensing” technology to determine the rotational position of each odometer wheel and its numerical value. The electronic reading of data for TouchRead and AMR applications is derived directly from the rotational position of the register’s odometer wheels, thereby insuring a totally-accurate reading value. The design eliminates mechanical wipers and contacts which are a source of friction that can result in wear that can cause malfunctioning. Also eliminated are snap-action spring mechanisms that add a load to the meter’s measuring element. Through “magnetic-field position sensing”, each of the eight odometer wheels is fitted in the hub area with a very small coil winding connected in parallel with a capacitor. (Figure 9). The odometer assembly is located within a wire cage, to which an alternating magnetic field is applied when the register is being interrogated for a reading. When the alternating magnetic field is applied, the coil / capacitor on each wheel resonates at a different frequency, depending on the capacitor value used The Sensus ICE Register extends the use of the ASCII-based communication protocol first utilized by Sensus in 1984. The meter reading data, which consists of the odometer reading and register ID number, are transmitted in ASCII code, the standard data code used by most of the data communications industry. ASCII encoding methodology requires that a complete reading of a register wheel contain 10 bits of information, which includes a “start,” “stop” and a “parity” bit. The parity bit is used as a self-check to insure that the interrogation device has correctly received the data from each wheel. Although additional data fields have been incorporated, it can be read by any handheld or AMR reading device that could read earlier ECR registers. Now widely considered to be the defacto industry standard, the Sensus 3-wire AMR interface protocol is made available free of charge to other AMR equipment manufacturers, thereby promoting ECR register compatibility with present and future AMR networks. I M P R O V E D R E S O L U T I O N F O R T ESTING AND VISUAL READING With its eight active odometer wheels, testing the accuracy of a water meter fitted with an ICE Register is greatly enhanced. Visual readings are more precise by a factor of one hundred, thereby enabling a precise comparison with the volume “standard” of the testing equipment. Decimal points on the dial face are used to separate whole units from fractional measurement Page 5 of 6 AMR-300-R1 units. Following tradition, the meter’s unit of measurement, gallons, cubic feet or cubic meters, is imprinted on the dial face. PERMANENT , F A C T O R Y - S E T I D NUMBER As with its predecessors, ICE Registers incorporate a unique, neverduplicated identification number that is factory-set into the register’s non-volatile electronic memory. The exclusive ID number can be used to identify a particular meter and link it in a utility ’s billing computer to the customer served by that meter. UTILITY PRO G R A M M A B L E A unique feature, the Sensus ICE Register has four data fields that can be programmed by a utility for incorporating and gathering useful information. One field could be used to identify the register’s unit of measurement. Another to identify a reading multiplier. A third, 12-character field could be used to incorporate a unique ID number. Its 20-character alphanumeric data field could be used to indicate meter size, a customer account number or address, or to identify the utility to protect against inadvertently picking up readings from an adjoining utility’s meters. TWO OR THR E E - W I R E R E G I S T E R INTERROGAT I O N T E C H N O L O G Y The Sensus ICE Register can be interrogated in either two-wire mode or three-wire AMR mode, which makes it totally compatible for incorporation into existing systems such as two-wire TouchRead or three-wire RadioRead, PhoneRead or fixed based systems. This feature makes it easy and economical for a utility that starts out with a TouchRead System to easily upgrade to a more-advanced AMR system without having to replace the registers on its meters. WATERPROOF PACKAGING An important requirement for insuring meter reading integrity and accuracy is to protect a register’s electronic components from moisture, dirt, sunlight and mechanical damage. This is crucial for meters installed under ground in meter boxes and vaults that are subject to flooding, as the potential exists for moisture to pass through a register’s molded polycarbonate cover and damage its electronic components. Sensus ICE Registers incorporate a patented, impenetrable barrier film to protect their electronic components just as effectively as does a hermetically-sealed register on a standard, visual-read meter. The design has been proven effective in more than ten years of use in extremely harsh conditions. PROTECTION OF WIRING CONNECTIONS Another important requirement for maintaining reading integrity is to insure that wiring connections are protected from moisture, and especially critical for providing long-term operational stability in pitset environments. To prevent moisture-infiltration, connection components on Sensus electronic registers are encapsulated (“potted”) at the factory with a special epoxy material under carefullycontrolled conditions. ASSURANCE TESTING Throughout the development of the Sensus ICE Register, an exhaustive series of performance tests were conducted to insure that specifications for reliable, long-term performance would be met. In addition to testing to assure reading validity in many of situations, registers were exposed to environments simulating harsh environmental conditions that might be encountered in actual installations. Because the ICE Register uses magnetic-field position sensing to obtain readings, a special emphasis was placed on testing for possible influences from external radiated electro-magnetic fields such as electro-static discharges from a nearby high-power radio transmitter. Throughout their testing, the registers proved to be even more-robust than their predecessors, providing assurance of dependable, troublefree performance. Page 6 of 6 AUTHORIZED SENSUS DISTRIBUTOR P.O. Box 487 | 450 North Gallatin Avenue Uniontown, PA 15401 USA T: 1-800-638-3748 F: 1-800-888-2403 www.sensus.com/water h2oinfo@sensus.com