Experimental Protocol for Cantilever Beam Bending Test

advertisement

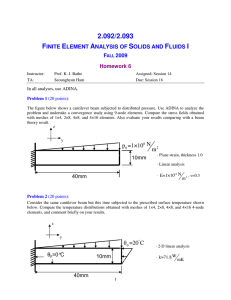

Experimental Protocol for Cantilever Beam Bending Test Several methods may be used to determine the Young modulus and Poisson ratio of a material [1]. A simple technique, based in a cantilever beam bending test, can be used in educational and training labs using generic laboratory equipment. Test Specimen Design The test specimen design comprises the following steps: The first step is material selection (aluminium, steel, carbon fibre, ABS, …); The specimen geometry should take into account the standard market offer concerning rectangular cross section size range; The specimen should be carefully clamped at one end and the other end will be left free for applying the normal loading (Note: the cantilever beam length inserted inside the clamping device should be around twice the cantilever beam width); The maximum strain at the clamped end should correspond to stress values of around 50% of the yield stress of the selected material (Note: lab weight sets providing a total force of around 25 N are easily available in the market); The specimen dimensions should be designed in order to provide suitable maximum strain values for the available load range. Test Protocol The cantilever beam should be instrumented with resistance strain gauges which will be integrated in Wheatstone bridge circuits; Each strain gauge is to be glued following the standard procedure [2] [3] and the geometric centre of each sensor should be at a distance from the clamping device around two times the transverse cantilever beam width; The calibrated loads should be applied always in the same application point in an increasing magnitude sequence (Note: for each load step the stabilization should be reached before the respective reading process); Admitting elastic behaviour the classic expression for Young modulus computed from the longitudinal strain measured value is E 6FL’⁄ ε bh (see Fig. 1). Experimental Test Example An online experiment entitled Mechanical Material Characterization is part of elabs FEUP (http://onlinelab.fe.up.pt/remote_exp.html) and the hands-on lab experiments are described in [2] [3]. Numerical Studies – Protocol Assessment In the Finite Element Method (FEM) studies an aluminium bar is used in a simple cantilever beam mounting layout as shown in Fig.1. The geometric characteristics of the rectangular cross section used are: width b = 0.0248 m and height h = 0.00388 m. The vertical load is applied at a distance L = 0.2121 m from the clamping device. The Maria Teresa Restivo, José C. Marques, Tiago Faustino Andrade and Bruno Santos October 2014 longitudinal and transverse strains are computed at a distance L' = 0.1645 m from the load application point. Clamping device Strain gauge Cantilever beam Figure 1. Cantilever beam setup for bending test. These studies, based in FEM analyses, will evaluate the influence of some parameters, such as: Poisson ratio; Boundary conditions; Distance from the sensor element centre to the clamping device; Shearing force contribution to bending deflection; Clamped support effectiveness. A. Poisson ratio and boundary conditions effects The first aspect to be studied is related to the Poisson ratio effect in bending, involving the relation between the longitudinal strain (εx) and the transverse strain (εy). The tensile longitudinal strain at the top face of the cantilever beam induces by Poisson effect a negative strain in the transverse direction which causes the edges of the top surface to move closer to each other (Note: the same effect appears in the bottom face but with a positive strain which enlarges the edge to edge distance). This effect is more pronounced with increasing bending moment values, i.e., as one approaches the clamping device. Fig. 2 illustrates this effect showing a coloured map of the transverse displacement component (dy) on the top face of the cantilever beam and provides a zoom on the boundary condition effect. Fig. 3 displays colour maps of the transverse strain (εy) distribution on the top face of the cantilever beam. It shows that the restriction to transverse strain introduced by the clamping device itself gives rise to a boundary condition effect, clearly visible in both Fig. 2 and Fig. 3. Both the transverse displacement (dy) and the transverse strain (εy) display a gradual transition to zero values as one gets closer to the clamping device. In both Figs. 2 and 3 it is also clear that the clamped end boundary effect is confined to a region whose length is approximately equal to the transverse cross section dimension (b). This explains the reason why it is frequently prescribed [2] [3] to glue the strain gauge so that its geometric centre is at a distance from the support o f 1 . 5 - 2 . 0 t i m e s t h e cantilever beam width (b). Maria Teresa Restivo, José C. Marques, Tiago Faustino Andrade and Bruno Santos October 2014 Figure 2. Colour map of the transverse displacement (dy) on the top face of the cantilever beam, with enlarged detail of the clamped end. Figure 3. Colour map of the transverse strain (εy) on the top face of the deformed cantilever beam, with enlarged detail of the top surface. Fig. 4 shows that the constraint of the transverse strain introduced by the clamped support produces a similar perturbation in its distribution in both the top and bottom faces of the cantilever beam. Note that the transverse strain is negative in the top face and positive in the bottom face. Figure 4. Colour map of the transverse strain (εy) on the top and bottom faces of the deformed cantilever beam. The animation in Fig. 5 shows the development of the transverse strain with varying applied load. Observing the lateral face of the cantilever beam it is possible to detect the neutral plane at mid-height. Maria Teresa Restivo, José C. Marques, Tiago Faustino Andrade and Bruno Santos October 2014 Figure 5. Transverse strain animation. B. Shearing force vs. bending moment contribution to deflection The second feature to be scrutinized is the contribution to the overall vertical deflection provided by the deformation due to the shearing force as compared to that due to the bending moment. The vertical deflection δ is given by: (1) In equation (1) L is the distance from the load application point to the clamping device, ⁄12 is the moment of inertia of the rectangular cross section, G is the modulus I ⁄2 1 of elasticity in shear (given by with ν being the Poisson ratio) and ⁄1.2 is the cross section reduced area [1]. The above expression makes it immediately clear that the contribution of the shearing force to the tip deflection is in this case over 3100 times lower than that of bending or, in other words, insignificant in practical terms. This shows that it is adequate to use equation (2) for the computation of the Young modulus value from the experimental results given by the bending test. E ’ (2) C. Clamped support effectiveness The deformability of the clamping device parts affects to a certain degree the system under test as well as the clamping support quality. Fig. 6 and Fig. 7 depict the longitudinal strain in the clamped area. The development of longitudinal strain is evident in the region of the cantilever beam within the clamping area. It is also noticeable the deformability of the lower clamping piece (Fig. 6). The parts of the clamping device should be made of stiffer material than that of the test piece in order to minimize these effects (Fig. 7). The animation in Fig. 8 shows both effects in a cantilever beam bending. Maria Teresa Restivo, José C. Marques, Tiago Faustino Andrade and Bruno Santos October 2014 Figure 6. Colour map of the longitudinal strain (εx) on the deformed cantilever beam considering an aluminium clamping device (same stiffness as the cantilever beam). Figure 7. Colour map of the longitudinal strain (εx) on the deformed cantilever beam considering a steel clamping device (higher stiffness than the cantilever beam). Figure 8. Cantilever beam bending animation. Maria Teresa Restivo, José C. Marques, Tiago Faustino Andrade and Bruno Santos October 2014 References [1] Ghali and A.M. Neville, Structural Analysis – A Unified Classical and Matrix Approach, 2nd ed., London: Chapman and Hall, 1978. [2] Maria Teresa Restivo: Maria Teresa Restivo, Fernando Gomes de Almeida, Maria de Fátima Chouzal, Joaquim Gabriel Mendes and António Mendes Lopes, "Handbook of Laboratory Measurements and Instrumentation", International Frequency Sensor Association (IFSA) Publishing, Barcelona, May 2011, ISBN: 97884-615-1138-9. [3] Maria Teresa Restivo, Fernando Gomes de Almeida, Maria de Fátima Chouzal, Joaquim Mendes e António Mendes Lopes, Laboratórios de Instrumentação para Medição, ISBN: 978-972-8025-67-0, Editora UPorto, Março 2008. Maria Teresa Restivo, José C. Marques, Tiago Faustino Andrade and Bruno Santos October 2014