σ ρ ρ ρ ρ

advertisement

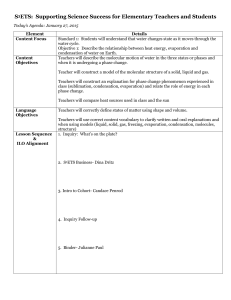

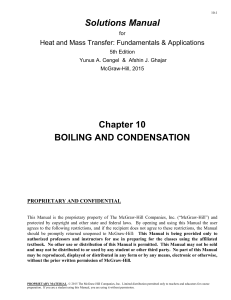

PROBLEM 10.10 KNOWN: Fluids at 1 atm: mercury, ethanol, R-134a. FIND: Critical heat flux; compare with value for water also at 1 atm. ASSUMPTIONS: (1) Steady-state conditions, (2) Nucleate pool boiling. PROPERTIES: Table A-5 and Table A-6 at 1 atm, Mercury Ethanol R-134a Water ρl ρv 3 (kg/m ) 3.90 1.44 5.26 0.596 hfg (kJ/kg) 301 846 217 2257 3 3 (kg/m ) 12,740 757 1,377 957.9 σ × 10 (N/m) Tsat (K) 417 17.7 15.4 58.9 630 351 247 373 ANALYSIS: The critical heat flux can be estimated by Eq. 10.6 with C = 0.149, 1/ 4 ⎡ σ g ( ρl − ρ v ) ⎤ q′′max = 0.149 h fg ρ v ⎢ ⎥ ⎢⎣ ⎥⎦ ρ v2 . To illustrate the calculation procedure, consider numerical values for mercury. q′′max = 0.149 × 301× 103 J / kg × 3.90kg / m3 × 1/ 4 ⎡ ⎤ ⎢ 417 × 10−3 N / m × 9.8 m / s 2 (12, 740 − 3.90 ) kg / m3 ⎥ ⎢ ⎥ 2 3 ⎢ ⎥ 3.90 kg / m ⎢⎣ ⎥⎦ ) ( q′′max = 1.34 MW / m 2 . For the other fluids, the results are tabulated along with the ratio of the critical heat fluxes to that for water. Flluid ( q′′max MW / m 2 ) q′′max / q′′max,water Mercury Ethanol 1.34 0.512 1.06 0.41 R-134a Water 0.281 1.26 0.22 1.00 < COMMENTS: Note that, despite the large difference between mercury and water properties, their critical heat fluxes are similar. PROBLEM 10.18 KNOWN: Nickel wire passing current while submerged in water at atmospheric pressure. FIND: Current at which wire burns out. SCHEMATIC: ASSUMPTIONS: (1) Steady-state conditions, (2) Pool boiling. ANALYSIS: The burnout condition will occur when electrical power dissipation creates a surface heat flux exceeding the critical heat flux, q′′max . This burn out condition is illustrated on the boiling curve to the right and in Figure 10.3. The criterion for burnout can be expressed as q′′max ⋅ π D = q′elec q′elec = I2 R ′e . (1,2) That is, 1/ 2 I = [ q′′maxπ D / R ′e ] . (3) For pool boiling of water at 1 atm, we found in Example 10.1 that q′′max = 1.26 MW / m 2 . Substituting numerical values into Eq. (3), find 1/ 2 I = ⎡⎢1.26 × 106 W / m 2 (π × 0.001m ) / 0.129Ω / m ⎤⎥ ⎣ ⎦ = 175 A. < COMMENTS: The magnitude of the current required to burn out the 1 mm diameter wire is very large. What current would burn out the wire in air? PROBLEM 10.40 KNOWN: Saturated water at 1 atm and velocity 2 m/s in cross flow over a heater element of 5 mm diameter. FIND: Maximum heating rate, q′ [ W / m ] . SCHEMATIC: ASSUMPTIONS: Nucleate boiling in the presence of external forced convection. 3 3 PROPERTIES: Table A-6, Water (1 atm): Tsat = 100°C, ρ l = 957.9 kg/m , ρv = 0.5955 kg/m , hfg -3 = 2257 kJ/kg, σ = 58.9 × 10 N/m. ANALYSIS: The Lienhard-Eichhorn correlation for forced convection with cross flow over a cylinder is appropriate for estimating q′′max . Assuming high-velocity region flow, Eq. 10.13 with Eq. 10.14 can be written as 1/ 3 ⎡ 1/ 2 ⎞ ⎤ ρ v h fg V ⎢ 1 ⎛ ρl ⎞3/ 4 1 ⎛ ρl ⎞ ⎛ σ ⎟ ⎥. q′′max = + ⎜ ⎟ ⎜⎜ ⎢169 ⎜ ρ ⎟ ⎥ 2 π 19.2 ρ ⎝ v⎠ ⎝ v ⎠ ⎝ ρ v V D ⎟⎠ ⎥ ⎢ ⎣ ⎦ Substituting numerical values, find q′′max = 1 π ⎡ 1 ⎛ 957.9 ⎞3/ 4 3 3 0.5955kg / m × 2257 ×10 J / kg × 2m / s ⎢ + ⎜ ⎟ ⎢⎣169 ⎝ 0.5955 ⎠ 1/ 2 ⎛ 1 ⎛ 957.9 ⎞ ⎜ ⎟ 19.2 ⎝ 0.5955 ⎠ 1/ 3 ⎤ ⎞ ⎜ ⎟ ⎜ 0.5955kg / m3 ( 2 m / s )2 0.005m ⎟ ⎝ ⎠ 58.9 ×10−3 N / m ⎥ ⎥ ⎥ ⎦ q′′max = 4.331 MW / m 2 . The high-velocity region assumption is satisfied if 1/ 2 q′′max ? 0.275 ⎛ ρl ⎞ +1 ρ v h fg V < π ⎜ ⎟ ⎝ ρv ⎠ 4.331× 106 W / m 2 0.5955kg / m3 × 2257 × 103 J / kg × 2 m / s ? 0.275 957.9 1/ 2 ⎛ ⎞ = 1.61< π ⎜ ⎟ ⎝ 0.5955 ⎠ The inequality is satisfied. Using the q′′max estimate, the maximum heating rate is q′max = q′′max ⋅ π D = 4.331MW / m 2 × π ( 0.005m ) = 68.0 kW / m. + 1 = 4.51. < COMMENTS: Note that the effect of the forced convection is to increase the critical heat flux by 4.33/1.26 = 3.4 over the pool boiling case. PROBLEM 10.49 KNOWN: Cooled vertical plate 500-mm high and 200-mm wide condensing saturated steam at 1 atm. & = 25 kg/h, (b) Compute FIND: (a) Surface temperature, Ts, required to achieve a condensation rate of m & ≤ 50 kg h , and (c) Compute and and plot Ts as a function of the condensation rate for the range 15 ≤ m & , but if the plate is 200 mm high and 500 mm wide (vs. 500 mm high and plot Ts for the same range of m 200 mm wide for parts (a) and (b)). SCHEMATIC: ASSUMPTIONS: (1) Film condensation, (2) Negligible non-condensables in steam. PROPERTIES: Table A-6, Water, vapor (1.0133 bar): Tsat = 100°C, hfg = 2257 kJ/kg; Table A-6, Water, liquid (Tf ≈ (74 + 100)°C/2 ≈ 360 K): ρ l = 967.1 kg/m3 , cp,l = 4203 J/kg⋅K, μl = 324 × 10-6 N⋅s/m2 , k l = 0.674 W/m⋅K,ν l = μl / ρ l = 3.35 × 10-7 m2/s. & = 25 kg/h = 6.94 × 10−4 kg/s, Reδ can be calculated from Eq. ANALYSIS: (a) With knowledge of m 10.36, & 4m = 4 × 6.94 × 10−4 kg/s 324 × 10-6 N ⋅ s / m 2 × 0.2 m = 429 Re δ = μlb Thus the flow is wavy laminar and Eq. 10.39 applies, from which ( hL = = ( ν 2l ) kl Re δ 1/ 3 / g) 1.08 Re1.22 δ − 5.2 0.674 W/m ⋅ K 2 ⎤1/3 ⎡ (3.35 × 10-7 m 2 /s)2 /9.8 m/s ⎣ ⎦ 429 = 7320 W/m 2 ⋅ K 1.22 1.08 × 429 − 5.2 Equation 10.34 can then be solved for Tsat – Ts, making use of Eq. 10.27, to give Tsat − Ts = & fg mh & p,l h L A − 0.68mc = 6.94 × 10−4 kg/s × 2257 × 103 J/kg ⋅ K = 22.0°C 7320 W/m 2 ⋅ K × 0.1 m 2 − 0.68 × 6.94 × 10−4 kg/s × 4203 J/kg ⋅ K Thus Ts = 78°C < This value is to be compared to the assumed value of 74°C used for evaluating properties. See comment 1. (b,c) Using the IHT Correlations Tool, Film Condensation, Vertical Plate for laminar, wavy-laminar and turbulent regions, combined with the Properties Tool for Water, the surface temperature Ts was & , considering the two plate configurations as indicated calculated as a function of the condensation rate, m in the plot below. Continued… PROBLEM 10.49 (Cont.) Plate temperature, Ts (C) 100 80 60 40 15 25 35 45 Condensation rate, mdot (kg/h) 500 mm high x 200 mm wide 200 mm high x 500 mm wide As expected the condensation rate increases with decreasing surface temperature. The plate with the shorter height (L = 200 mm vs 500 mm) will have the thinner boundary layer and, hence, the higher average convection coefficient. Since both plate configurations have the same total surface area, the 200mm height plate will have the larger heat transfer and condensation rates. For the range of conditions examined, the condensate flow is in the wavy-laminar region. COMMENTS: (1) With the IHT model developed for parts (b) and (c), the result for the part (a) & = 25 kg/h is Ts = 77.9°C (Reδ = 438 and h L = 7400 W/m2 ⋅ K) . Hence, the assumed conditions with m value (Ts = 74°C) required to initiate the analysis was a good one. (2) A copy of the IHT Workspace model used to generate the above plot is shown below. /* Correlations Tool - Film Condensation, Vertical Plate, Laminar, wavy-laminar and turbulent regions: */ NuLbar = NuL_bar_FCO_VP(Redelta,Prl) // Eq 10.38, 39, 40 NuLbar = hLbar * (nul^2 / g)^(1/3) / kl g = 9.8 // Gravitational constant, m/s^2 Ts = Ts_C + 273 // Surface temperature, K Ts_C = 78 // Initial guess value used to solve the model Tsat = 100 + 273 // Saturation temperature, K // The liquid properties are evaluated at the film temperature, Tf, Tf = Tfluid_avg(Ts,Tsat) // The condensation and heat rates are q = hLbar * As * (Tsat - Ts) // Eq 10.33 As = L * b // Surface Area, m^2 mdot = q / h'fg // Eq 10.34 h'fg = hfg + 0.68 * cpl * (Tsat - Ts) // Eq 10.27 // The Reynolds number based upon film thickness is Redelta = 4 * mdot / (mul * b) // Eq 10.36 // Assigned Variables: L = 0.5 // Vertical height, m b = 0.2 // Width, m mdot_h = mdot * 3600 // Condensation rate, kg/h //mdot_h = 25 // Design value, part (a) // Properties Tool - Water: // Water property functions :T dependence, From Table A.6 // Units: T(K), p(bars); xl = 0 // Quality (0=sat liquid or 1=sat vapor) rhol = rho_Tx("Water",Tf,xl) // Density, kg/m^3 hfg = hfg_T("Water",Tsat) // Heat of vaporization, J/kg cpl = cp_Tx("Water",Tf,xl) // Specific heat, J/kg·K mul = mu_Tx("Water",Tf,xl) // Viscosity, N·s/m^2 nul = nu_Tx("Water",Tf,xl) // Kinematic viscosity, m^2/s kl = k_Tx("Water",Tf,xl) // Thermal conductivity, W/m·K Prl = Pr_Tx("Water",Tf,xl) // Prandtl number PROBLEM 10.61 KNOWN: Array of condenser tubes exposed to saturated steam at 0.1 bar. FIND: (a) Condensation rate per unit length of square array, (b) Options for increasing the condensation rate. SCHEMATIC: ASSUMPTIONS: (1) Spatially uniform cylinder temperature. (2) Average heat transfer coefficient varies with tube row with n = -1/6 in Eq. 10.49. (3) Negligible concentration on noncondensable gases in the steam. PROPERTIES: Table A.6, Saturated water vapor (0.1 bar): Tsat ≈ 319 K, ρv = 0.067 kg/m3, hfg = 2393 kJ/kg; Table A.6, Water, liquid (Tf = (Ts + Tsat)/2 = 309 K): ρ l = 993 kg/m3, cp,l = 4178 J/kg⋅K, μl = 703 × 10-6 N⋅s/m2, k l = 0.627 W/m⋅K. ANALYSIS: (a) With Ja = c p,l ΔT/hfg = 4178 J/kg⋅K × (319 - 300)K/2393 × 103 J/kg = 0.033, h ′fg = hfg(1 + 0.68 Ja) = 2393 kJ/kg(1 + 0.68 × 0.033) = 2470 kJ/kg. Equation 10.46 may be written for the top tube, 1/ 4 ⎡ gρ ( ρ − ρ ) k3h′ ⎤ l l v l fg ⎥ h D = 0.729 ⎢ ⎢ μl ( Tsat − Ts ) D ⎥ ⎣ ⎦ 1/ 4 ⎡ 9.8 m s2 × 993 kg m3 ( 993 − 0.067 ) kg m3 ( 0.627 W m⋅ K )3 × 2470 × 103 J kg ⎤ hD = 0.729 ⎢ ⎥ −6 2 703 × 10 N ⋅ s m ( 319 − 300 ) K × 0.008 m ⎥⎦ ⎣⎢ h D = 11,190 W m2⋅ K . From Eq. 10.49 the array-averaged convection coefficient is h D, N = h D N n = 11,190 W/m2 ⋅ K × 10−1/ 6 = 7622 W/m2 ⋅ K Hence, the condensation rate for the entire array per unit tube length is & ′ = 7622 W m2⋅ K (100 ) π × 0.008 m ( 319 − 300 ) K 2470 × 103 J kg m < & ′ = 0.147 kg s ⋅ m = 530 kg h ⋅ m . m (b) Options for increasing the condensation rate include reducing the surface temperature and/or the number of tubes in a vertical tier. The following results were obtained using IHT. Continued... PROBLEM 10.61 (Cont.) mdot' (kg/s-m) 0.24 0.22 0.2 0.18 0.16 0.14 280 285 290 295 300 Ts (K) Condensation rate versus tube temperature (10 vertical tubes). mdot' (kg/s-m) 0.22 0.2 0.18 0.16 0.14 0.12 2 4 6 8 10 Number of vertical tubes Condensation rate versus number of vertical tubes (Ts = 300K). COMMENTS: Note the sensitivity of the condensation rate to the manner in which the tubes are positioned within the array.