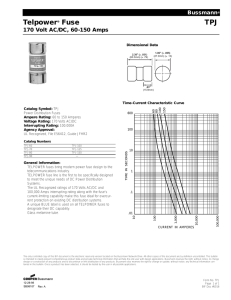

Application Information

advertisement