®

Model 916GA Safety Reversing Sensor Kit

WARNING

For use with models GA600 and GA650

Preparation

CAUTION

Before getting started, check carton inventory. Be sure

power to the opener is disconnected. Due to the variety

of gates and mounting applications, conduit and posts are

NOT PROVIDED. Refer to your local hardware store for

PVC conduit, mounting posts and additional hardware

that may be needed.

CARTON INVENTORY

Anchors (4)

WARNING

WARNING

To prevent SERIOUS INJURY or DEATH:

• DISCONNECT power BEFORE installing the safety reversing

sensors.

• Correctly connect and align the safety sensors.

• Install the sensor so beam is NO HIGHER than 24" (61 cm)

above ground.

• Gate MUST be fully closed BEFORE installing the safety

sensors.

• This product is for use with Chamberlain GA600 and GA650

gate openers ONLY. Use with other than recommended

equipment voids warranty, and may cause property damage

or SERIOUS personal INJURY.

Grommets (2)

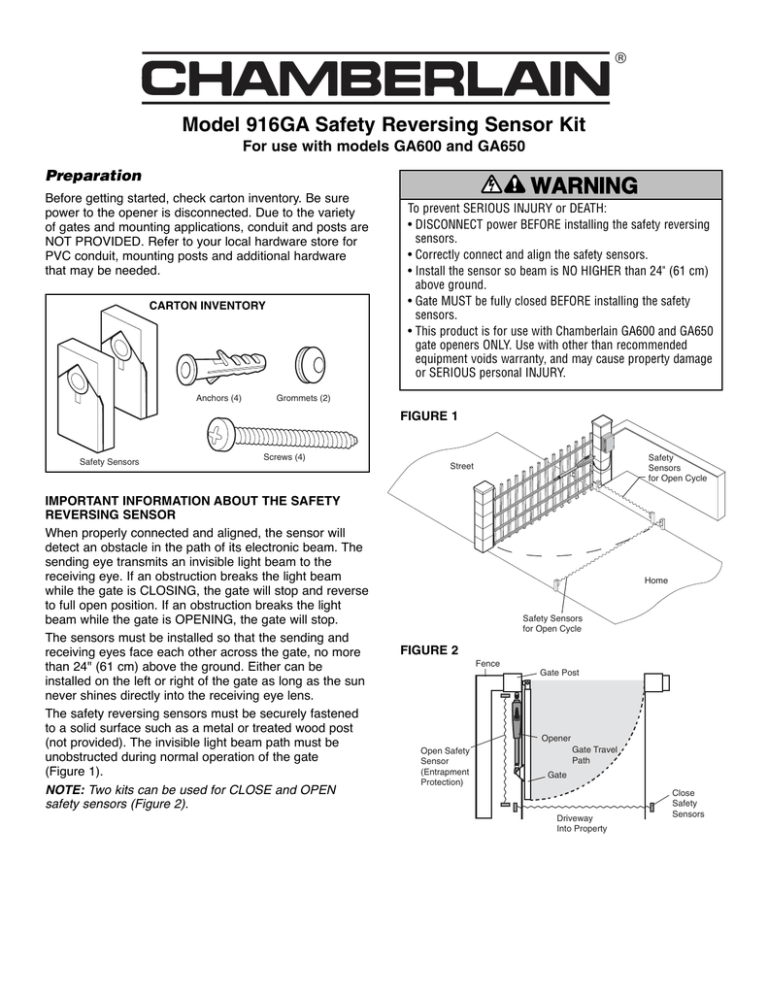

FIGURE 1

Safety Sensors

Screws (4)

IMPORTANT INFORMATION ABOUT THE SAFETY

REVERSING SENSOR

When properly connected and aligned, the sensor will

detect an obstacle in the path of its electronic beam. The

sending eye transmits an invisible light beam to the

receiving eye. If an obstruction breaks the light beam

while the gate is CLOSING, the gate will stop and reverse

to full open position. If an obstruction breaks the light

beam while the gate is OPENING, the gate will stop.

The sensors must be installed so that the sending and

receiving eyes face each other across the gate, no more

than 24" (61 cm) above the ground. Either can be

installed on the left or right of the gate as long as the sun

never shines directly into the receiving eye lens.

The safety reversing sensors must be securely fastened

to a solid surface such as a metal or treated wood post

(not provided). The invisible light beam path must be

unobstructed during normal operation of the gate

(Figure 1).

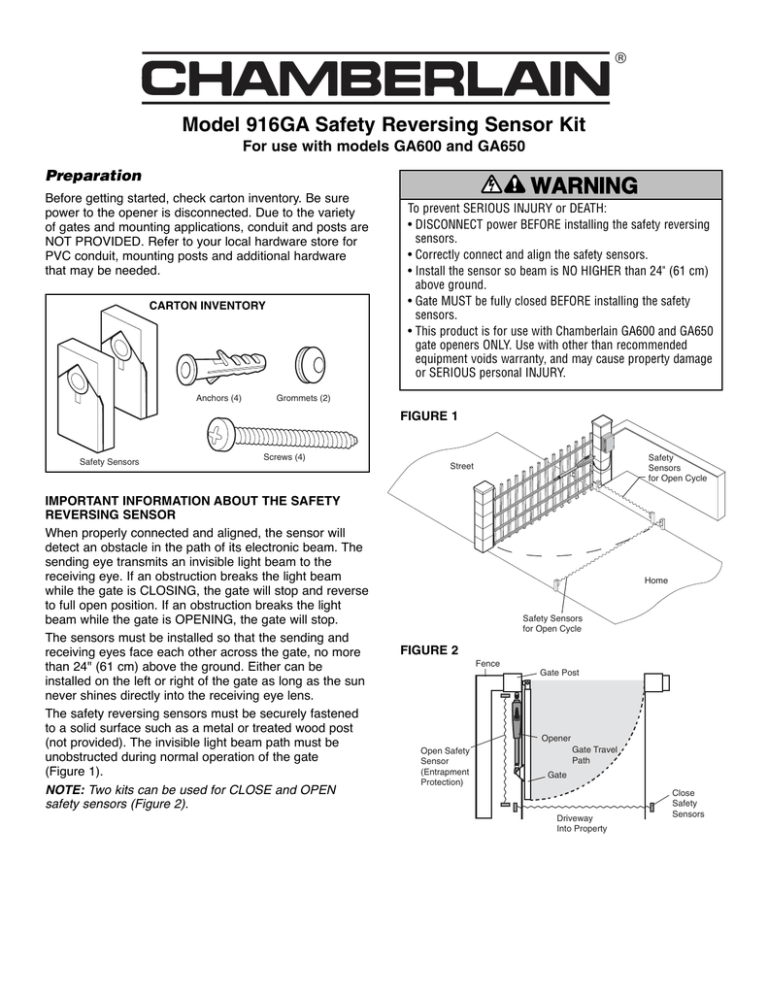

NOTE: Two kits can be used for CLOSE and OPEN

safety sensors (Figure 2).

Safety

Sensors

for Open Cycle

Street

Home

Safety Sensors

for Open Cycle

FIGURE 2

Fence

Gate Post

Opener

Open Safety

Sensor

(Entrapment

Protection)

Gate Travel

Path

Gate

Driveway

Into Property

Close

Safety

Sensors

Installation

FIGURE 3

Open Safety Sensors

P2

OPEN

PHOTO

R223

CLOSE

EDGE

K6

BROWN

BLUE

R2Ø7

Z2Ø

R227

K5

OPEN EDGE/

PHOTO

L1

Z22

R92

OFF

Z9

MAGLOCK

Z8

OPEN

PHOTO

CLOSE

R91

F3

BLUE

ON

LEARN

XMITTER

R1

R94

K2

BROWN

R224

U4

R2

Z8

CLOSE

PHOTO

DIAGNOSTIC

R93

GATE 1

K1 Q9

SET

OPEN

LIMIT

SET

CLOSE

LIMIT

LEARN

LIMITS

GATE 2

TIMER

RUNNING

COM

OVLD

CONTROL

INPUTS

TIMER TO

CLOSE

FORCE

R1Ø1

OPEN

R1ØØ

CLOSE

PHOTO

SINGLE BUTTON

BROWN

BLUE

F4

RESET

ACCESSORY

OVLD

STOP

K4

OFF

MAX

COM

F5

COM

POWER

R35

D8

C12

D27 Z3

F7

Z4

C13

D22

LOOP

INPUTS

C4

SHADOW

U3

INTERRUPT

C11

COM

CHGR

OVLD

BLUE

D9

K3

Q22

BROWN

D21

F6

F2

R9

MOV1

JMPR1

D2

U2

DB1

F1

D4

D1

C64

JMPR2

FUSE

OPEN

BATT 2

BATT 1

D6

114A3263

FIGURE 4

P1

NOTE: For close safety sensors, install and align the

sensors so they will face each other across the driveway,

with the beam no higher than 24" (61 cm) above the

ground. The close safety sensors will also require a saw

cut or trench across the driveway for wiring.

1. Disconnect power to opener.

2. Use a metal or treated wood post (not provided) to

elevate the sensors. The lenses should be no higher

than 24" (61 cm) above the ground.

3. Measure and position the safety sensors at the same

height above the ground.

4. Securely fasten sensors to post with hardware

provided (Figure 3).

5. Bury safety reversing sensor wires.

a. OPEN safety sensors:

• Dig a narrow trench about 6" (15 cm) deep from

the sensor mounting post to the control box. Make

sure not to damage any wires already trenched.

b. CLOSE safety sensors:

• Saw cut or trench across the driveway for wiring.

• Dig a narrow trench about 6" (15 cm) deep from

the sensor mounting post to the control box. Make

sure not to damage any wires already trenched.

6. Locate knockout on the bottom of the control box.

Measure and cut a piece of PVC conduit (not

provided) to install from the control box to the bottom

of the trench. Route the sensor wires through the

conduit with 1/2" (12 mm) sealed fitting.

7. Connect wires in the control box.

a. OPEN safety sensors:

• Connect wires to P7 terminal. This will pause an

opening gate until the obstruction has been

removed. Upon removing the obstruction, the gate

will continue to open. This will have no effect on

the gate closing.

b. CLOSE safety sensors:

• Connect wires to P9 terminal. This will reverse a

closing gate to the full open position (open limit).

This will have no effect on a gate opening. The

Timer-to-Close will not reactivate at the open limit.

8. Reconnect power to opener. The indicator lights in

both the sending and receiving eyes will glow steadily

if wiring connections and alignment are correct.

9. Alignment is necessary if the LED flashes (when the

invisible light beam is not blocked). Loosen the

receiving eye so that slight movement is possible.

Adjust the sensor vertically and/or horizontally until the

red LED is lit and no longer flashes.

Close Safety Sensors

Test the Safety Reverse

1. Press the remote control button to open the gate.

2. Place an obstruction in the path of the gate.

3. Press the remote control button to close the gate.

The gate should stop or stop and reverse depending on

the application. The gate opener will not close from a

remote if the indicator light in either sensor is off (alerting

you to the fact that the sensor is misaligned or

obstructed). If the unit continues to fail the Safety

Reverse Test, call for a trained gate systems technician.

Troubleshooting

If the sending or receiving LEDs do not light up after

installation, please check the following:

a. Power supply to the opener.

b. Short-circuit in the black/white cable. This can

happen beneath clamps or at the connecting

terminals.

c. Incorrect wire connections between the sensor and

opener.

d. Interruption to the power supply circuit (broken wire).

If both sensors are flashing:

a. Align sensors.

b. Remove obstruction.

© 2006, The Chamberlain Group, Inc.

All Rights Reserved