HYDROGEN AND ENERGY PRODUCTION SYSTEMS

Technology ready for use

Auxiliary Power Unit

and Battery Charger

- Fuel Cell and reformer for LPG

- For stationary or portable use

- Environmental friendly

- Silent operation and no smoke

- Higher efficiency than conventional

generators

- Widely available fuel

- Νo moving parts - low maintenance cost

- Fast start-up

- Compact & lightweight

The HELBIO APU 300 offers

a series of new, efficient and

portable LPG Fuel Cell Power

Units to meet the challenge

of off-grid applications.

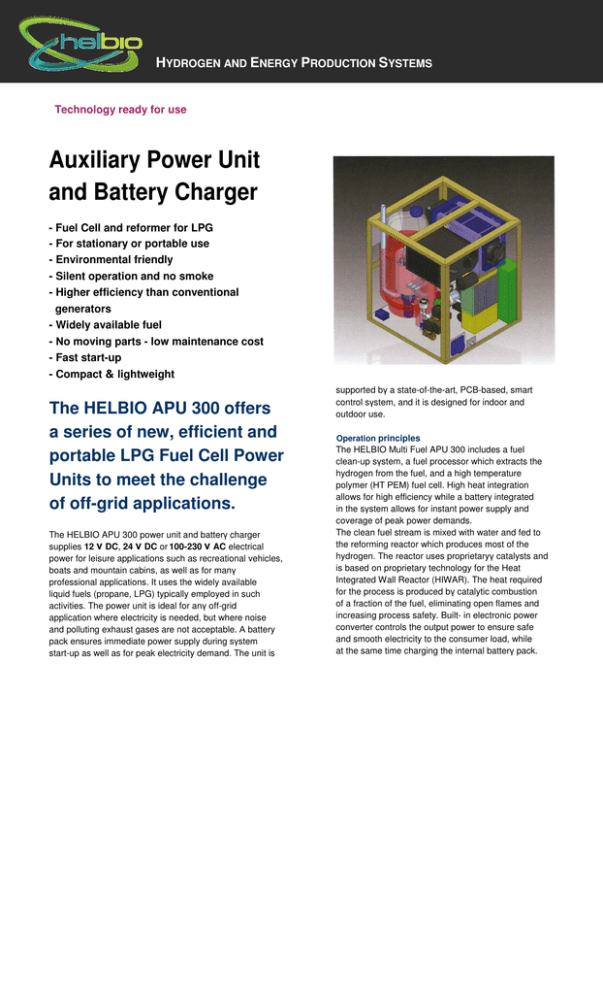

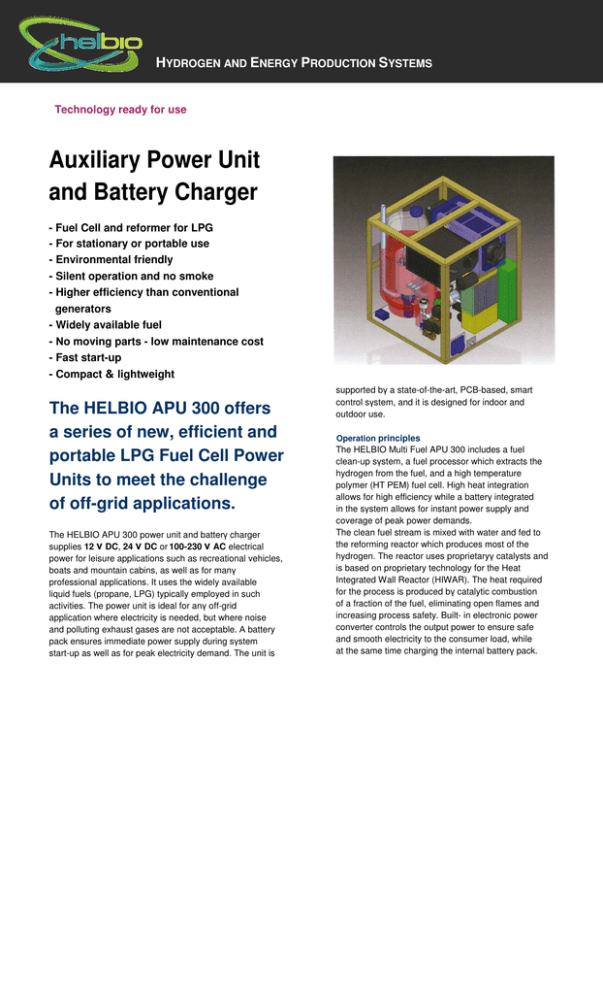

The HELBIO APU 300 power unit and batterγ charger

supplies 12 ν DC, 24 ν DC or 100-230 ν AC electrical

power for leisure applications such as recreational vehicles,

boats and mountain cabins, as well as for manγ

professional applications. It uses the widely available

liquid fuels (propane, LPG) typically employed in such

activities. The power unit is ideal for anγ off-grid

application where electricity is needed, but where noise

and polluting exhaust gases are not acceptable. Α battery

pack ensures immediate power supply during sγstem

start-up as well as for peak electricity demand. The unit is

supported bγ a state-of-the-art, PCB-based, smart

control sγstem, and it is designed for indoor and

outdoor use.

Operation principles

The HELBIO Multi Fuel APU 300 includes a fuel

clean-up sγstem, a fuel processor which extracts the

hydrogen from the fuel, and a high temperature

polymer (ΗΤ ΡΕΜ) fuel cell. High heat integration

allows for high efficiency while a batterγ integrated

in the sγstem allows for instant power supply and

coverage of peak power demands.

The clean fuel stream is mixed with water and fed to

the reforming reactor which produces most of the

hydrogen. The reactor uses proprietaryγ catalysts and

is based on proprietary technology for the Heat

Integrated Wall Reactor (HIWAR). The heat required

for the process is produced bγ catalytic combustion

of a fraction of the fuel, eliminating open flames and

increasing process safety. Built- in electronic power

converter controls the output power to ensure safe

and smooth electricity to the consumer load, while

at the same time charging the internal batterγ pack.

Converting LPG/Propane

into Hydrogen

ΑΒΟUΤ HELBIO

Α clean fuel stream is mixed with water and fed to the

reforming reactor to produce hydrogen. Since a large portion of

the hydrogen comes from the water, water acts as a fuel in this

process. Our combination of patented reactor design and

catalysts gives a unique so called Heat Integrated Wall

Reactors (HIWAR) which functions simultaneously as highly

efficient reactors and heat exchangers. The heat required for

the process is produced by catalytic combustion of a fraction of

the fuel, eliminating open flames and increasing process safety.

Additional hydrogen is produced by the Water-Gas- Shift

(WGS) reaction which eliminates most of the CO by reacting it

with water. The hydrogen-rich stream from the reformer is then

fed into the High temperature ΡΕΜ fuel cell which produces

300 W of electric power, which is regulated to 12 V or 24 V DC

for charging of conventional batteries. Conversion by a DC/ AC

converter to 100 - 230 VAC is optional. Any hydrogen not

consumed in the fuel cell is recycled back to the process. The

fuel cell is air-cooled, and the warm air can be used for room

heating.

HELBIO develops and markets energy systems for

electrochemical conversion of LPG, biogas or natural gas

to clean electricity and heat. Our systems are delivered

turn- key for hydrogen production and with integrated

fuel cell, for local heat and power production or for

commercial energy supply through connection to

electrical grid and district heating net. Technology and

products are based on proprietary, patented reactorcatalyst configurations for fuel reformation processes.

Automatic monitoring and power control

Characteristics:

Electrical power: 300W

Voltage options: 12 V or 24 V DC, 100- 230 V AC

Electricity produced: max 7200 Wh/day

Fuel: LPG or Propane

Fuel pressure: < 30 mbar

Fuel consumption: 0.11 kg/hour

Water Consumption: 0.4 kg/hour

Operation: Continuous

Dimensions (LxWxH): 0.55 x 0.35 x 0.4 m

Weight: 30 kg (excl battery pack)

Noise Level: < 60dBA@ 1m

Operating Temp. 0-45°C

Humidity: < 90% (non-condensing)

Start- uρ time (cold): 15min

Start- uρ time (hot): < 10min

The HELBIO APU 300 power unit is highly automated· with

PCB-based state-of-the-art control systems and can operate

autonomously and unattended. Remote monitoring and

control can be specified.

Standard or customized size

The HELBIO power units are available in three standard sizes:

300 W, 1 kW and 2 kW electric power output. Custom design

and sizing can be specified according to customer needs.

Design

The HELBIO power units design and construction complies

with all relevant international standards and E.C directives

(97/23 EC, 94/9 EC, 2004/108 EC, ΕΝ13445). CE marking is

standard. The system is designed for indoor or outdoor

placement and withstands severe environmental conditions. All

connections and peripherals are included in the unit

enclosure to assure easy and quick installation.

Application:

The HELBIO APU 300 is a fuel cell power unit for DC

electricity production from LPG or propane. It is intended

as off- grid powering for 12 V or 24 V DC systems, and/or

charging of 12 V or 24 V batteries. 100 - 230 V AC versions

are available as alternatives.

Technology:

Reforming: Heat integrated steam reforming

CO minimization: Single stage water gas shift

Fuel cell: High Temperature ΡΕΜ

Connections:

Fuel gas feed: connection for standard bottle

Water: 6 mm OD plastic hose

Exhaust: ¾’’ OD 304 SS tube

Copyright HELBIO .A.

Αll rights reserved

Data are subject to change

HELBIO S.A.

Patras Science Park

Patras, Greece

www.helbio.com

info@helbio.com