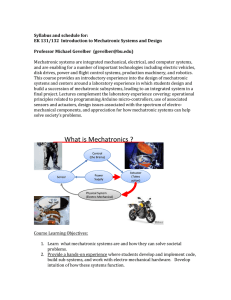

Mechatronic Systems: An Introduction

advertisement

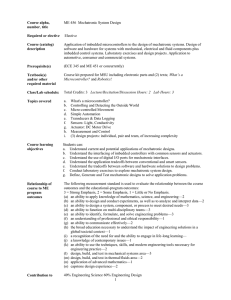

Mechatronic Systems An Introduction (Higher) 6526 HIGHER STILL Spring 2000 Mechatronics Mechatronic Systems An Introduction Higher Support Materials CONTENTS MECHATRONICS WHAT IS IT? The Microprocessor a) The Central Processing Unit (CPU) b) The Memory c) The Bus system Sensors and Actuators a) The Analogue actuator b) The Digital actuator c) The Analogue signal d) The Digital signal WHAT IS A TRANSDUCER? What is a sensor? What is an actuator? Well!!! Is it a sensor or is it an actuator? a) Sensors b) The microswitch c) The inductive proximity sensor d) The thermocouple e) Flow sensors f) The pressure transducer g) Actuators Hydraulic and Pneumatic Actuators a) The hydraulic/pneumatic cylinder b) The hydraulic/pneumatic rotary actuator Electrical Actuators a) The DC motor b) The stepper motor c) Stepper motor operation What is control? Closed loop control Open loop control DET: Mechatronic Systems: An Introduction (Higher) 1 System Inputs and Outputs a) Processes and Sub processes b) Input sub-processes c) Output sub-processes d) Interfaces e) Buses f) Programs MECHATRONIC SYSTEMS EXAMINED Automatic camera Automatic washing machine Automatic assembly machine Automotive engine management system Vending machine Computer controlled fitness equipment Pick and place robot INTELIGENCE (WHERE DOES IT FIT IN)? The Personal Computer (pc) a) PC Architecture b) The CPU c) The Memory d) The Bus Syste e) Input and Output Units (I/O) f) Operating system Hardwired Logic a) Design b) Truth Tables c) Boolean expression d) The logic circuit e) Programmable Logic Devices (PLD) f) System On Chip (SOC) The Application Specific Integrated Circuit (ASIC) a) The ASIC what is it? b) ASIC applications c) ASIC Design DET: Mechatronic Systems: An Introduction (Higher) 2 Microcontrollers a) What is a microcontroller? b) The needs of embedded control c) The Basic Stamp microcontroller d) The original Parallax Basic Stamp e) The Higher Still developed Basic Stamp Controller f) Intel 8XC196MC Industrial Motor Control Microcontroller g) Intel Automotive 80C31BH/80C51BH/87C51 Microcontroller Programmable Logic Controllers PLC’s a) What is a Programmable Logic Controller? b) PLC Central Processing Unit (CPU) c) PLC Memory d) PLC Input/Output e) PLC Programming Languages f) Ladder Logic Controller Types Reviewed a) PC based b) Embedded controller c) Microcontroller d) Programmable Logic Controllers e) Hardwired Logic PROGRAMMING Compiled Languages Interpreted Languages Low-Level Computer Languages High-Level Computer Languages a) FORTRAN b) BASIC c) Pascal d) C Very High-Level Languages Natural Languages Object-Oriented Programming a) Smalltalk b) C++ c) Turbo Pascal DET: Mechatronic Systems: An Introduction (Higher) 3 DET: Mechatronic Systems: An Introduction (Higher) 4 MECHATRONICS: WHAT IS IT? There is no definitive answer to this question. The word ‘mechatronics’ means different things to different people. In simplistic terms Mechatronics is: the intelligent control of plant, product or process To the author of this document, mechatronics is a combination of five distinct disciplines: 1. Electrical engineering 2. Mechanical engineering 3. Electronic engineering 4. Software engineering 5. Control engineering Why do we need to cover so many areas when there probably already exist many engineers in each of the fields shown above? In some industrial design and manufacturing companies two engineers of different disciplines may be working together. One of the engineers sees something, which impinges on the other engineering discipline, but rather than deal with it directly he will talk to his manager. This manager will then talk to the second engineers’ manager the information will then travel by way of the two managers to the second engineer. Obviously this is an extremely wasteful process. Most of the time this is done because of a lack of experience and knowledge of the other engineer’s area of work. Mechatronics overcomes this unfamiliarity and breaks down the barriers by allowing people to work in harmony as part of a multidisciplinary engineering team. This saves companies time and money and adds to the job satisfaction of the engineer. What is a mechatronic system? Mechatronics is the: intelligent control of plant, product or process What does this mean? In the case of an automated system it means that, in general, underlying intelligent controller(s) control all parts of the system (or overall process). DET: Mechatronic Systems: An Introduction (Higher) 5 These controllers can take many forms: • Personal Computer (PC) • Embedded controller • Microcontroller • Programmable Logic Controller (PLC) • Application Specific Integrated Circuit (ASIC) All of these controller types, apart from the ASIC, have at their heart a device called the microprocessor or µP. What is a microprocessor? The Microprocessor A microprocessor in its simplest form is a large collection of transistors arranged in such a way as to provide blocks on a single piece of silicon otherwise known as a Very Large Scale Integration (VLSI) device. On the silicon are constructed areas for the following:- short-term data storage or memory, computation and logical functions Arithmetic Logic Unit or ALU, various registers that allow for data manipulation and a program counter. This is known collectively as the Central Processing Unit or CPU. Control circuitry is also included in order to allow Input/Output functions or I/O. In order that these blocks can communicate with one another links between them are also included. This collection of inter block links are known as buses as they transport information or data around the processor. The Central Processing Unit (CPU) The Central Processing Unit is the ‘brain’ of the microprocessor. All instructions are processed by the CPU, all logic and mathematical functions are carried out by the Arithmetic Logic Unit (ALU) and all data movement around and in and out of the microprocessor is co-ordinated from within the CPU. All of this co-ordination comes about because of an underlying sequence of instructions held within memory, the program. The program can be user defined and stored in temporary memory or it may be processor resident, put there by the manufacturer and known as micro-code. The Memory Memory comes in two formats. The first type is Read Only Memory (ROM), which as it states can only be read. No data can be written to this type of memory. ROM generally has the program ‘burned’ into it by the manufacturer and is permanent even when power is removed. This type of memory is said to be nonvolatile. The second type is Random Access Memory (RAM). This memory can have data read from and or written to it repeatedly but it loses its contents when power is removed. This type of memory is said to be volatile. There are usually small areas of both of these types of memory manufactured into the microprocessor. The amount of each type of memory included within each microprocessor varies with the manufacturer. DET: Mechatronic Systems: An Introduction (Higher) 6 The ROM area is where micro code required for the correct internal operation of the CPU will reside. RAM will allow dynamically changing data to be temporarily stored and used within the operation of a user program. Both ROM and RAM memory exists in larger amounts external to the microprocessor as well. This is where large application programs and data would be stored and again this memory is accessed directly by the microprocessor via the buses. ADDRESS BUS I/O or Memory CTRL BUS Central Processing Unit CTRL BUS Memory or I/O DATA BUS Microprocessor architecture There are three buses involved in the processor: The Bus system • The data bus transfers data and instructions between memory and the CPU or between the CPU and the memory. Data movement is bi-directional with the direction being set by the control bus. • The control bus carries various signals that control the way the system responds to both internal and external commands. Internal commands include the setting of direction of data flow on the data bus whether memory is being read from or written to and whether the memory being accessed is actually part of the input/output area as data handling commands differ for I/O operations. This bus can vary considerably between different processors, is more complex than the other buses and is dependent on the processor manufacturer (INTEL, MOTOROLA, AMD, ZILOG….) Note: In the diagram above the control bus marked ‘CTRL BUS’ although it appears twice, is actually the same bus. • The address bus allows the CPU to pinpoint individual memory locations within the system memory map. These memory locations originate from the CPU and are dependent on whether the information required is program code or raw data. This bus only has to work in one direction and so is known as uni-directional. DET: Mechatronic Systems: An Introduction (Higher) 7 Let’s have a look at the READ/WRITE sequences within the processor. When the Central Processing Unit (CPU) accesses a program which is stored in memory or stores information obtained from external sensors the following sequence of events must occur: READ (Memory) • identify the address location in memory by placing its value on the address bus • identify to memory that the READ function is required via the control bus • memory makes available the data on the data bus • processor READs the data WRITE (Memory) • identify the address location in memory by placing its value on the address bus • identify to memory that the WRITE function is required via the control bus • processor places the data on the data bus • memory is updated to now hold the new DATA value READ (I/O) • identify the address location in the I/O map by placing its value on the address bus • identify to the I/O memory location that the READ function is required via the control bus • the I/O memory location makes available the data on the data bus • processor READs the data WRITE (I/O) • identify the address location in the I/O map by placing its value on the address bus • identify to the I/O memory location the WRITE function is required via the control bus • processor places the data on the data bus • the I/O memory location is updated to now hold the new DATA value DET: Mechatronic Systems: An Introduction (Higher) 8 Sensors and Actuators Sensors and actuators come in two main categories namely analogue and digital. An explanation of these two terms is given. The Analogue actuator The analogue actuator can take up any position within the limits of its movement as in the case of the pneumatic linear actuator shown below. stroke length Analogue pneumatic actuator Similarly the speed of a rotary actuator motor is continuously changeable across its range. The Digital actuator The digital actuator, shown below, will only take up position at one end or the other of its stroke. exhaust fluid in stroke length limit sw limit sw Voltage Digital pneumatic actuator The Analogue signal By definition analogue signals: are continuously and infinitely variable over the range of measurement as can be seen in the graph below. Temperature Continuously variable analogue signal DET: Mechatronic Systems: An Introduction (Higher) 9 In the graph above the voltage rises smoothly, it has no visible steps, as the temperature rises. If we wish to find a value at any instant in time we will get a value that is representative of the original signal. Note that this is not the only waveform that constitutes an analogue signal. Voltage The Digital signal By definition digital signals: are discrete signals which will not change until the next level is reached. Temperature A thermometer measuring in 5o jumps. In the graph above the voltage does not rise smoothly, it has visible steps, as the temperature rises. If we wish to find a value at any point we will only get a value that is as close to the nearest step value available. DET: Mechatronic Systems: An Introduction (Higher) 10 WHAT IS A TRANSDUCER? 1 Transducer (sensor): is any device that converts a non-electrical parameter, for example, sound, pressure, or light into electrical signals or vice versa. The variations in the electrical parameter are a function of the input parameter What is a sensor? • a microphone converts sound into electrical energy • a thermocouple converts heat energy into a change in voltage • a switch converts mechanical movement into one of two possible electrical states. What is an actuator? An actuator, in a control system, is a device which converts energy from one form into another: • a speaker converts electrical energy into sound • a solenoid converts electrical energy into mechanical motion • a motor converts electrical energy into rotational motion. WELL!!! IS IT A SENSOR OR IS IT AN ACTUATOR? This is a classic question, and can only be answered by asking yourself a few questions: • is the device doing a job, does it move something? If the answer is ‘yes’ then the chances are that the device is an actuator • if on the other hand it provides a changing signal then it is likely that it is a sensor. 1 Young E.C. 1988. Dictionary of Electronics, Penguin. DET: Mechatronic Systems: An Introduction (Higher) 11 Sensors Below is a list of sensors commonly found in a Mechatronics system. Sensor name Microswitch Float switch Photoelectric Type Digital Digital Digital Inductive Digital Conductive Capacitive Ultrasonic LVDT Linear potentiometer Rotary potentiometer Magnetic reed switch Infra red Analogue Digital Digital/analogue Analogue Analogue Analogue Digital Digital Thermocouple Strain gauge Piezoelectric crystal Analogue Analogue Analogue Moire fringe Hall effect Digital Analogue/digital Tacho generator Analogue Vane anemometer Analogue Usage End stop - limit switch Liquid level detection Through beam Retro-reflective Diffuse Background/foreground suppression (BGS/BFS) Fibre optic Proximity detector Shielded sensor Unshielded sensor Distance sensing Level sensing Proximity detector Level/depth sensors Linear displacement Linear displacement Angular displacement End stop – limit switch Reflective proximity can be used for positional or as part of a shaft encoder arrangement to provide a stream of pulses Temperature measurement Force displacement Pressure displacement Among others Linear positioning Position; can be used within a shaft encoder to supply a stream of pulses Speed control; driven permanent magnet motor will give a voltage proportional to the speed of rotation Fluid flow We will now take a look at a few of these sensors in more detail. DET: Mechatronic Systems: An Introduction (Higher) 12 The microswitch Switch2: A device that causes the operating conditions of a circuit to change between discrete specified levels. The ‘micro’ in microswitch refers not to the physical size of the device but the actuation movement required to open or close the contacts from Normally Closed (NC) to Normally Open (NO). The internal operation of the microswitch can be seen in the figure below: normally closed nc common com normally open no Microswitch Microswitches, which are digital in operation, are used extensively to detect end of stroke movement. The microswitch requires physical contact in order to operate, is mechanical in operation and consequently has a restricted life due to the flexing operation of its internal mechanism. The microswitch may also be found in a nonmechanical, non-contact, inductive proximity format as well. The inductive proximity sensor The inductive proximity sensor consists of a coil wound around a ferrite core at the sensing head. A high frequency signal is applied to this, generating an oscillating electromagnetic field around it as shown in the figure below. This is monitored by the internal electronics. copper coil electronics Proximity detector When a metallic object travels towards the field, electric currents are generated within it. As the object approaches the sensing face of the sensor these currents increase in size. 2 Young E.C. 1988. Dictionary of Electronics: Penguin. DET: Mechatronic Systems: An Introduction (Higher) 13 The currents cause a transformer like effect and as a result the energy in the detecting coil lessens and the oscillations reduce. As the object moves in closer the oscillations finally stop. Sensing distances are usually quoted by the manufacturers and are dependent on the target material type and target size. The sensing distance quoted in the device specifications for the proximity sensors are based on a standard target. This target (known as a standard object) is a square plate of mild steel 1 mm thick, a primarily ferrous object. standard target Bring the target towards the sensor sensing distance (operating position) Sensing distance diagram When the target reaches the point where the sensor operates, this is the sensing distance as shown above. release position sensing distance (operating position) Sensor release diagram The sensor will release turn off at a point slightly further from the sensing face as shown above. Sensing distances quoted by manufacturers are against a standard mild steel object. If however a different metal is used, the sensing distance will be reduced. These reductions can be seen in the table below. Mild steel 100% Iron 100% Stainless steel 70% Lead 50% Brass 40% Aluminium 30% Copper 25% Sensing distance reductions Metals with different types and thickness of plating affect the detecting distance of inductive sensors. This effect will vary depending on the type and thickness of the plating material. DET: Mechatronic Systems: An Introduction (Higher) 14 Where other target materials are to be used for example paper, card or plastic other proximity detectors exist that will sense these materials. The thermocouple The thermocouple, shown below is a sensor used in the monitoring of temperature. As a sensor it has a relatively simple construction. Two wires of different metallic materials are brought together and bonded, usually in a high temperature arc welding process. The result of this process leaves a sensor that generates very small voltages proportional to a rise in temperature. These voltages can be amplified and used within a mechatronic system to allow temperature control. welded tip Thermocouple The thermocouple comes in many forms to cover the temperature ranges as listed in the table below. Minimum continuous temperature Maximum continuous temperature Maximum spot reading Type J -60 Type K Type N Type T -200 -230 -200 Type R -50 +1100 +400 +1350 O C +1100 +1300 +1320 +500 Thermocouple temperature ranges +1400 O C +850 +1300 Units O C Below is a graph showing a typical temperature gradient for Type K thermocouples. The 3Graph above shows that the Type K thermocouple output is linear and usable over quite a large range of temperatures from approximately –100OC to 400OC. Note: thermocouples are only one of a variety of sensors available for temperature control. 3 Courtesy of RS Components DET: Mechatronic Systems: An Introduction (Higher) 15 Flow sensors Measurement of flow is required in many automated processes. The simplest method of flow measurement uses a device known as a turbine. This device, however, is by nature intrusive. That is, it must fit inside the system and be moved directly by the fluid being monitored, and so it must be realised that this type of device will restrict the flow while measuring it. The diagram below shows a simple flow sensor in operation. sensing coils Flow ω magnetic inserts Flow sensor As the liquid flows through the pipe it forces the turbine to turn. As the blades rotate the magnetic inserts pass in close proximity to the sensing coils, this induces a current in the coils. If these coils are placed symmetrically around the outside of the pipe then a series of pulses will be produced. Information about speed of rotation of the turbine can then be converted into the rate of flow of the fluid within the pipe. For a very good description of the paddlewheel sensor, point your browser at: http://www.sensorsmag.com/articles/1299/63_1299/main.shtml Where you will find an article named: Paddlewheel Flow Sensors: The Overlooked Choice Another type of flow measurement device, which can be used without restricting the flow of the liquid within the pipe, is the ultrasonic flowmeter. These devices can be strapped onto the outside of the pipe and use sound to calculate rate of flow. DET: Mechatronic Systems: An Introduction (Higher) 16 How does it work? First a suitable site must be found, then the ‘sensor rack’ which contains an ultrasonic transmitter and an ultrasonic receiver built in, is wrapped around the pipe see diagram below. direction of flow ultrasound transmitter ultrasound receiver Pulses of sound are emitted by the transmitter, this sound is reflected by the back wall of the pipe, but because of the fluid flow the pulses are forced to travel downstream. Electronics within the system measure the difference in time between the pulses and using maths the distance travelled can be calculated. These systems are known as ‘time of flight’ measurement devices. For a very good description of ultrasonic flowmeters, point your browser at:http://www.sensorsmag.com/articles/1097/flow1097/main.shtml Where you will find an article named: Ultrasonic Flowmeter Basics These are not the only type of flow measurement device and so below are a few other devices that can be used. A B A B (a) Nozzle. (b) Venturi Both of these devices require that a difference in pressure be monitored. Operation of these devices is described on page 15. This leads us to the last sensing device we will examine, the pressure transducer. DET: Mechatronic Systems: An Introduction (Higher) 17 The pressure transducer The pressure transducer is used in many differing locations such as the monitoring of industrial pneumatic supplies, oil pressure in hydraulic systems and gas flow to list only a few. We will, however, examine only one use flow measurement as seen on the previous page. We will examine the integrated circuit type pressure sensor shown below. stainless steel diaphragm sensor element external connections Integrated circuit pressure sensor The pressure transducer shown above has a resistive element at the heart of the sensor unit. This is a very small strain gauge manufactured directly into a piece of silicon. A stainless steel diaphragm protects the delicate sensor element from any direct contact. As the pressure builds up the stainless steel diaphragm bends downwards and as the canister is hermetically sealed the pressure on the sensor element changes. This change in pressure causes the strain gauge to bend and so there is a change in the resistance of the gauge. This variable resistor forms one leg of a bridge circuit as shown below. The other side of the strain element is the reference port that the measuring port is compared to. All pressure transducers have two sides. Sometimes the reference side has it’s own pressure connection and the device is known as a differential pressure transducer. constant current in voltage out voltage out reference element sensing element ground Strain gauge bridge DET: Mechatronic Systems: An Introduction (Higher) 18 In the case of the venturi in the figure below; there are two pressure tapping points ‘A’ and ‘B’. In order that continual monitoring of the rate of flow can be carried out the pressure difference between these two points must be known. This can be carried out by installing either two pressure sensors as shown previously or by employing a differential type to provide the information. The information from the transducer/s is then used to calculate the final rate of flow. A B Venturi sensor For a good description of pressure sensor technology, point your browser at: http://www.sensorsmag.com/articles/1198/fun1198/main.shtml Where you will find an article called Fundamentals Of Pressure Technology Note: It is worth visiting the site http://www.sensorsmag.com as there is a wealth of information on all aspects of sensors to be found here. DET: Mechatronic Systems: An Introduction (Higher) 19 Actuators Below is a list of actuators commonly found in a Mechatronics system: Actuator name Stepper motor Solenoid Type Digital Digital Actuation Rotational Linear & rotational Pneumatic cylinder Analogue/digital Linear Hydraulic cylinder Analogue/digital Linear DC motor Analogue Rotational AC motor Analogue Rotational Work type Positional Mechanical displacement Relay Air flow control Mechanical displacement This type of device comes in many forms from purely digital linear operation, to analogue linear operation and from purely digital rotational operation to analogue rotational operation Linear or rotational displacement Direct drive Servo control Direct drive Closed loop control such as harmonic drive. Hydraulic and Pneumatic Actuators The hydraulic/pneumatic cylinder: The word hydraulics comes from the Greek hudraulos – a musical organ driven by waterpower. The word hydraulics is used to describe a system where mechanical power is transmitted through a liquid that is under pressure. The braking system in a car is usually hydraulic. The brake pedal actuates a piston inside the master cylinder. This forces the brake fluid along a pipe, at the other end of which the fluid enters an actuator, which usually operates another piston. This presses the brake linings against the brake drum, which stops the car. This is shown below: exhaust fluid in Brake piston DET: Mechatronic Systems: An Introduction (Higher) 20 Fluid forced in under pressure at the right hand side of the cylinder pushes the piston to the left. Fluid on the left of the piston is exhausted from the connector on the lefthand side thereby forcing the internal piston to the left imparting linear motion. If on the other hand fluid is being forced in on the left side and fluid is allowed to exhaust on the right then the piston will move to the right, again imparting linear motion. Hydraulic fluid is generally a mineral oil. The same diagram and description will also suffice to explain the action of a pneumatic system in which the oil is replaced by compressed air. The main difference between these two systems is their ability to do work. Air is compressible even when it has previously been compressed to 100 psi. This fact means that pneumatic systems are limited to relatively light loads. Hydraulic systems on the other hand can do many times more work due to the incompressibility of oil. The hydraulic/pneumatic rotary actuator Another type of actuator exists which will create rotary motion, as seen in the figure below. rotation fluid in exhaust Hydraulic/pneumatic rotary actuator Electrical Actuators The DC motor Many electric motors, from the motor used in a toy to the motor in a battery powered shaver are direct-current (DC) motors. A battery is a source of DC and will power a motor of this type. Mains electricity provides power which changes polarity fifty times per second and is known as Alternating Current (AC), which is no use for driving a DC motor. By adding a rectifier circuit, however, we can produce useable DC power to drive a DC motor. armature brushes stator field coils magnet commutator magnet rotor DC motor DET: Mechatronic Systems: An Introduction (Higher) 21 Housed in a metal case is the stator, which is a series of permanent magnets. Enveloped in this is the armature constructed of coils of copper wire or field coils. As current is passed through the coils the electromagnetic action produced repels the field of the permanent magnet and causes rotary motion. Each field coil is energised in turn by way of the commutator and brush arrangement. The stepper motor Unlike a conventional DC motor, where the driven shaft simply spins, the stepper motor rotates in small and very precise steps. If the motor has 12 steps per revolution, then each incremental movement will be exactly 30 degrees. Powering a stepper motor is not as simple as connecting the terminals to a power supply, as in the DC motor. Specialised electronic circuitry is required external to the motor in order that the motor’s movement can be controlled. The physical size of these circuits has been radically reduced over the years to the point where now they are available for purchase in the form of a specialised Integrated Circuit (IC). This control IC is connected directly to a programmable unit, usually a computer, which allows program control of the device. Stepper motors are employed in many areas where movement must be controlled precisely. For example in Numerically Controlled (NC) machine tools where the workpiece must moved through fractions of a millimetre. Stepper motors can also be found inside the printer connected to the computer, where they control both the movement of the paper and the print head. Stepper motor operation The rotor, the moving part, in a stepper motor is constructed from several permanent magnets with both North and South poles. The stator, the fixed part, is wound into a series of electromagnets that can be switched ON and OFF. In Diagram (a) below, the two electromagnets that are activated are at 12 o’clock and at six o’clock, the magnetic fields generated by these electromagnets attract and hold rigidly the rotor poles N3 and S2. Note that the rotor poles have the opposite magnetic field to the electromagnets. Like poles repel opposites attract. In Diagram (b) below, the winding power has now been switched to 3 o’clock and 9 o’clock; this action drags the rotor round to the 9 o’clock position. This constitutes one step. If these coils are switched OFF and the next pair switched ON the rotor would move one more step. If we therefore continuously switch pairs of coils ON and OFF, in sequence, then we can produce rotational movement. ON OFF Stator Rotor Stator Rotor S N3 OFF N N2 N1 ON N1 OFF S1 S3 S3 S1 N3 N2 S2 S ON S2 N ON OFF Diagram a Diagram b Stepper motor action DET: Mechatronic Systems: An Introduction (Higher) 22 What is control? Is a man with a box and arrow taking aim an open or closed loop control system? Closed loop control Closed as the man will adjust his aim to take care of wind direction or movement of the target etc. When the trigger is pulled and the arrow leaves the box is it an open or closed loop system? Open loop control Open as the arrow can not change its trajectory whilst in flight. It cannot adjust to compensate for unexpected external influences. System Inputs and Outputs All of the previously mentioned system controllers require information to be passed from external influences to the controller (system inputs) and from the controller to the system under control (system outputs). External Influences SYSTEM INPUTS Controller SYSTEM OUTPUTS System Under Control Information transfer can take a number of forms: • analogue signals from sensors (temperature, flow, and light level…) • digital signals from sensors (mechanical switches, proximity detectors…) • user inputs interface (man machine interface: keyboard or start/stop buttons…) • analogue devices under control actuators (motors, heaters, light levels…) • digital devices under control actuators (stepper motors, warning lights, solenoids…) • user outputs interface (machine man interface: monitor, head up display, mimic diagrams…) Digital Sensors Digital Actuators Controller Analogue Sensors DET: Mechatronic Systems: An Introduction (Higher) Analogue Actuators 23 Processes and Sub-processes Any processing carried out between the sensor and the controller or between the controller and actuator is known as a sub-process. Digital Sensors Analogue Sensors P R O C E S S Controller P R O C E S S Digital Actuators Analogue Actuators Input sub-processes Digital information may require little, if any, processing before passing to the controller. (This might include switch de-bounce, pulse shaping and code conversion.) Analogue information generally requires more processing to present it to the controller in a useable condition. (This might include amplification, filtering and analogue to digital conversion.) Output sub-processes Digital information may require processing before passing to the actuator. (Darlington current drivers…) Analogue information generally requires more processing to present it to the actuator in a useable format. (digital to analogue conversion, filtering…) DET: Mechatronic Systems: An Introduction (Higher) 24 Interfaces In order to protect the system controller and the end user from possible dangers due to the malfunction of internal or external power supplies, controllers must be isolated from the devices connected to them. This isolation is normally placed at the interface between the input devices and the controller or the controller and output devices. Digital Sensors Digital Actuators Input Interface Controller Output Interface Analogue Sensors Analogue Actuators Along with this isolation the interface may also accommodate the signal conditioning electronics needed for both the digital and analogue inputs and outputs. Digital Sensors Digital Interface Digital Interface Digital Actuators Analogue Interface Analogue Actuators Controller Analogue Sensors Analogue Interface Man - machine interfaces These come in many formats but in general allow the user to interact directly with the overall system. (Examples are a control panel, keyboard or mouse driven graphical representation.) Machine - man interfaces These allow the current system status to be displayed to the user. (Examples are a head-up display, VDU, display panel or mimic diagram.) Buses The interconnections between any of the controllers and the various sub-systems are generally known as buses. They transport information, data, around the system. Some of these buses are internal, within the controller, some are external to the controller. All of these processes must interact for the overall system to operate correctly. This is made possible by using a list of commands to control system behaviour. Each controller has its own set of commands or language. DET: Mechatronic Systems: An Introduction (Higher) 25 Programs A program is a structured list of commands that can be made to collect status information from the external sub-system sensors, process this information and act to make the sub-systems carry out the required process steps. The program is normally stored within the controller and each controller can have a different method of inserting the program. Mechatronic systems examined Lets look at some Mechatronic systems now. Automatic camera Take Photo Use Flash Aperture output I/P Interface Programmable Unit O/P Interface Light Condition Shutter output Film wind • the user would simply indicate the use of flash or not then press the button to take the photo • the light condition and the user I/P information would provide I/P data for the I/P interface • the I/P interface would condition the I/P signals for the programmable unit • the programmable unit would process the I/P information as per the internal program and deliver appropriate desired O/P signals to the O/P interface • the O/P interface would condition the O/P signals for the O/P actuators • the aperture would be set for best photograph • the shutter speed would be set and activated • the film would then be wound on for the next photo. Automatic washing machine Door Closed Drawer Closed Program Selected Cold Water Fill Water Level I/P Interface Programmable Unit Temp Level DET: Mechatronic Systems: An Introduction (Higher) Motor Wash Cycle Motor Spin Cycle O/P Interface Hot Water Fill Waste Pump 26 The user would insert clothing to be washed: • close the door; -- door closed would be sensed • select the washing program; -- The program selection would be sensed and stored ready for use • put the fabric conditioning products in the drawer and close it; -- drawer closed would be sensed • the I/P interface would condition any sensor signals for the programmable unit • the programmable unit would process the input signals with respect to the chosen washing program and deliver appropriate O/P signals for the O/P actuators. Note: this system has at least two closed loop control systems: water temperature and water level. Automatic assembly machine • the system is being asked to move from one location to another in order to deliver Position Z axis X axis actuator Position X axis Z axis actuator I/P Interface Position Y axis Programmable Unit O/P Interface End effector Tactile info Y axis actuator a component to a pre-loaded position • position information is fed back from all the axes (X, Y and Z along with tactile info) via the I/P interface • the I/P interface would condition the I/P signals for the programmable unit • the programmable unit would process the I/P information as per the internal program and deliver appropriate desired O/P signals (speed, velocity, position…) to the O/P interface • the O/P interface would condition the O/P signals for the O/P actuators • the X axis position attained • the Y axis position attained • the Z axis position attained • the end effector can be operated in order to deliver the component. Automotive engine management system Fuel Level Speed Limiter Engine Speed I/P Interface Throttle Position Programmable Unit Engine Temp DET: Mechatronic Systems: An Introduction (Higher) O/P Interface Head up Display Fuel Delivery 27 The Engine Management System (EMS) takes control of many aspects of the car: • as the driver presses down on the accelerator so the information from the throttle position sensor is passed to the I/P interface • the I/P interface conditions the I/P signal for the programmable unit • the programmable unit processes this signal as per the internal program and delivers suitable O/P signals to the O/P interface • the O/P interface conditions this signal and feeds it to the fuel delivery system • at the same time, info from the engine speed sensor is passed to the I/P interface which conditions the signal and passes it on to the programmable unit • the programmable unit processes this information as per the internal program and delivers an appropriate signal to the O/P interface • the O/P interface conditions this O/P signal for the O/P actuators • the speed limiter can be activated if over reving engine • the engine speed can be sent to the head up display for the user • the fuel level signal can be fed again through the I/P interface • converted to a useable format • acted on by the programmable unit processed by the internal program and provided to the O/P interface • the O/P interface conditions the signal for the O/P actuators • fed to the head up display for user • also used to display fuel consumption • engine temperature likewise is sent to the I/P interface • conditioned for the programmable unit • processed by the internal program and provide the O/P interface with a signal • the O/P interface conditions this signal for the O/P actuators • this signal is fed into the head up display for the user • the signal is also used to set fuel mixture levels. Vending machine Payment made Selection Output I/P Interface Programmable Unit Selection made O/P Interface Item Output • the customer would make payment – Correct payment would be sensed and indicated at the I/P interface • the customer would make selection – any selection made would be sensed and indicated at the I/P interface • the I/P interface would condition the sensor signals for the programmable unit (controller) • the programmable unit would process the sensor I/P signals as per the internal program and deliver appropriate desired O/P signals to the O/P interface. DET: Mechatronic Systems: An Introduction (Higher) 28 • the O/P interface would condition the O/P signals for the O/P actuators • the selection O/P actuator would select the desired item • the selected item would be delivered to the customer. As for the remaining systems it is left up to the reader to produce their own versions. Computer controlled fitness equipment Pick and place robot DET: Mechatronic Systems: An Introduction (Higher) 29 INTELIGENCE (WHERE DOES IT FIT IN)? Control sub-systems. The Personal Computer (PC) IBM designed the original PC, the IBM PS/2, back in the early seventies. This was a radical move away from the mainframe and microcomputer of the early days. It was aimed at the business market, for the small to medium sized office where it would be used for word processing, databases and spreadsheets. IBM PS/2 From the start they had very limited memory, 64K maximum, and by today’s standards uncomfortably small hard disk drives around 10 MB, if they had a hard disk at all. The operating system or O/S, more about this later, was a text based operating system and not the graphical systems we are so used to today. PC Architecture MEMORY INPUTS OUTPUTS INPUT INTERFACE UNIT OUTPUT INTERFACE UNIT ADDRESS BUS CPU DATA BUS CONTROL BUS The PC architecture (note other format on page 3) The CPU The Central Processing Unit is the ‘brain’ of the microprocessor. All fetch-execute instructions originate from the CPU, all logic and mathematical functions are carried out within the CPU and all data movement around the microprocessor is co-ordinated by the CPU. All of this co-ordination comes about because of an underlying sequence of instructions held within memory, the program. The program can be user defined or may be processor resident, put there by the manufacturer, known as micro code and is stored in memory. The Memory Memory comes in two formats. Read Only Memory (ROM); this memory as it states can only be read from, no data can be written to this type of memory. DET: Mechatronic Systems: An Introduction (Higher) 30 ROM generally has the program burned into it by the manufacturer and is permanent even when power is removed. This type of memory is said to be non-volatile. Random Access Memory (RAM); this memory can have data read from and or written to it repeatedly but will lose its contents when power is removed. This type of memory is said to be volatile. There are usually small areas of both of these types of memory manufactured into the microprocessor. The amount of each type of memory included within each microprocessor varies with manufacturer. The ROM area is where micro code required for the correct internal operation of the CPU will reside. RAM will allow dynamically changing data to be temporarily stored and used within the operation of a user program. Both ROM and RAM memory exists in larger amounts external to the microprocessor as well. This is where large user written programs and data would be stored; again this memory is accessed directly by the microprocessor via the buses. The Bus System There are three buses involved in the processor: • the data bus that transfers data and instructions between memory and the CPU or between the CPU and the memory, movement of data is bi-directional. Direction is set using the control bus. • The control bus carries various signals that control the way the system responds to both internal and external commands. Internal commands include the setting of direction of data flow on the data bus, whether memory is being read from or written to, whether the memory being accessed is actually part of the Input/Output area, as the data handling commands differ for I/O operations. This bus can vary considerably between different processors, is more complex than the other buses and is dependent on the processor manufacturer (INTEL, MOTOROLA, AMD, ZILOG….) • The address bus allows the CPU to pinpoint individual memory locations within the system memory map. These memory locations originate from the CPU and are dependent on whether the information required is program code or raw data. This bus only has to work in one direction and so is known as uni-directional. Input and Output Units (I/O) Input. Communication with the computer is via some kind of input unit, which can generally handle several peripherals. This communication is often referred to as the man-machine interface. For example, the keyboard is an input device that interfaces with the input unit and allows the operator to enter data, programs and operating system commands into the computer. The mouse is another input device that allows a graphical pointer to be easily moved about the video screen by the operator. DET: Mechatronic Systems: An Introduction (Higher) 31 Output The computer communicates with us (the user) via the output unit, which can generally handle several peripherals (external devices, printer, plotter, modem etc.). This communication is known as machine-man interface. For example, the output unit allows information from the computer to be displayed on a video monitor or to be printed by a printer. There are of course devices that act both as input and output devices. Examples are disk drives, tape drives and modems. Buses The CPU is connected to other internal parts of the computer by three sets of parallel connections called buses, since they transport the information around the computer. The data bus carries the data for processing and is a two-way or bidirectional system this can be 4, 8, 16 lines, each line carrying one bit at a time. The address bus is a one-way or uni-directional system and conveys, as it’s name implies, the various addresses required by the CPU, and has anything from 4 to 32 lines depending on the number of memory addresses. The final bus, the control bus deals with timing signals and may have 3 to 10 or even more lines. Operating system Consider when we are writing and running a program in say assembly language we start by: • run the editor program → create a text file from the keyboard • temporarily store the text file • start up the compiler program • compile the stored text file → assembly language file • store this program • start up the assembler • produce a machine language file from the stored assembly language file • finally you link the assembly language program with other pre-assembled subroutines and library routines. • now you can finally run your program. For all of these above operations consider what is taking care of all the transfer of information between keyboard and PC, between microprocessor and RAM, from RAM to (disk drive), between the disk drive and PC etc..? These are some of the tasks of the operating system, a large complex program that oversees the loading of user programs (the ones you write) and utility programs (editor, compiler, assembler linker etc.) as well as the handling of I/O and interrupts, the creation and manipulation of files. DET: Mechatronic Systems: An Introduction (Higher) 32 Some popular operating systems can be seen in the table below: MS-DOS Windows 9x Windows NT OS/2 UNIX LINUX MacOS Vertex Used on early IBM© PC’s and clones pre-1995; still used on some. Used on later IBM© PC’s and clones 1995 on Used on later IBM© PC’s and clones 1995 on Used on IBM© PC’s successor (version also available for PC) Created by Bell Labs; widely used on mainframe computers Created by Linus Torvald as a UNIX-like operating system for PC’s as UNIX does not run on PC’s Created for Apple Mac computer systems Created as an off-the-shelf operating system There are also other operating systems available off-the-shelf for including in your own designs, but they are complex. These operating systems can be found included with some Microcontrollers and ASICS whilst others have Operating Systems specifically written for them by the manufacturers. DET: Mechatronic Systems: An Introduction (Higher) 33 Hardwired logic There is a requirement that 3 switches A, B and C activate an alarm unit (X) when the switch configuration matches the following criteria: The alarm (X) should sound whenever: • Switch A is ‘HI’ and B is ‘LO’ or • Switch A is ‘HI’ and C is ‘LO’ This problem mimics the type of safety system fitted to many industrial processes such as the component access doors on a 10-ton machine press. Such a system has a sensor, ‘A’, fitted to make sure the doors are firmly closed and there is no possibility that the operators can have their hands within the press’s work envelope. The second input, ‘B’, comes from a foot-operated switch. The third input, ‘C’, checks for the presence of a component within the press. Design To start the design for this section design tools will be employed that you may well have not come across yet. You will not be required to remember these methods, but they are being used here to prove a point. In the design criteria above there are three inputs to the controller and one output. If we have three inputs then we have a possible eight combinations at these inputs. Truth Tables But we are only interested in certain combinations, where the output (alarm) is to be on. This can be seen in the truth table (a) below; remember, HI = 1 and LO = 0. Firstly we are looking for any input status line where A = 1, B = 0 and C can have any value. A 0 0 0 0 1 1 1 1 I/P s B C 0 0 0 1 1 0 1 1 0 0 0 1 1 0 1 1 Truth table (a) O/P X Where these input conditions arise we want to see a HI or 1 at the output. DET: Mechatronic Systems: An Introduction (Higher) 34 This is shown in Table (b) below: A 0 0 0 0 1 1 1 1 I/P s B C 0 0 0 1 1 0 1 1 0 0 0 1 1 0 1 1 Table x (b) O/P X 1 1 Now we are looking for any input status line where A = 1, C = 0 and B can have any value. A 0 0 0 0 1 1 1 1 I/P s B C 0 0 0 1 1 0 1 1 0 0 0 1 1 0 1 1 Table (c) O/P X 1 1 Again where these input conditions arise we want to see a HI or 1 at the output: A 0 0 0 0 1 1 1 1 I/P s B C 0 0 0 1 1 0 1 1 0 0 0 1 1 0 1 1 Table (d) O/P X 0 0 0 0 1 1 1 0 For all other input conditions we want the output to be LO or 0: This can be seen in Table (d) above. Boolean expression The Boolean expression for the above truth table is: DET: Mechatronic Systems: An Introduction (Higher) A.B .C + A.B .C + A.B.C 35 The logic circuit If we use standard logic gates we can put together a logic circuit that could replicate the above requirements. Logic schematic diagram This type of circuit is known as hardwired logic because these gates have to be physically wired together for the circuit to operate. Many pieces of equipment still exist that utilise hardwire logic. The above circuit would require no fewer than four separate integrated circuits: 1 x HEX INVERTER... 2 x QUAD 2 input AND.. 1 x QUAD 2 input OR…. Programmable Logic Devices (PLD) Unless the circuit is small or only required once, its function could be designed more efficiently using Programmable Logic Devices PLD’s. These devices are in integrated circuit format with arrays of INVERTERs, AND and OR gates all on one chip. The interconnections between the gates are like a mesh of interconnected fuses. The designer would probably design the circuit function using hardwired logic to test its operation and then use special software and hardware to blow the individual fuses within the IC. This would create a circuit which would operates exactly as the hardwired logic circuit, but on a single IC. System On Chip (SOC) This reduction of large discrete circuits onto single IC’s is one of the biggest reasons for the growth of the home computer market. The PC of 5 years ago required cards that plugged into the motherboard and had such functions as VGA monitor driver card, serial I/O, parallel I/O and the modem. Today, most of these functions are included on the motherboard itself and are implemented in special integrated circuits. This has all come about as the density of circuit functions in integrated circuits has increased. This is known as System On Chip or (SOC). DET: Mechatronic Systems: An Introduction (Higher) 36 The Application Specific Integrated Circuit (ASIC) The ASIC what is it? The Application Specific Integrated Circuit (ASIC) is a semi-custom or custom device which is designed and manufactured to meet a customer’s individual specification. The ASIC is a large collection of transistors arranged in such a way as to provide areas of short-term storage or memory, computation and logic functions and input/output functions. In fact the microprocessor is a general example of an ASIC. This does not mean that all ASIC’s are microprocessors as ASIC’s can be designed to carry out many diverse functions. Remember the customer determines the function of an ASIC. ASIC applications The Application Specific Integrated Circuit as described above is also known as a System On Chip or SOC. Some of the applications that have been addressed by the ASIC are as follows: • control of camera shutter speed, focus, light level • data acquisition systems • in a microprocessor with A/D and D/A, pulse width modulation, timers etc (this device is known as a microcontroller) • in a PC to allow fast graphics to be displayed (3D accelerator) • mobile phones (encoder/decoder chips…) • development timer/processing circuit for accurate timing in explosive units. The chip consists of a digital processing part, rectifier and an internal oscillator • development and production of a chip for brake wear out applications, consists of a digital processing unit, ROM, Digital to Analogue Converter (DAC) and an internal oscillator • development for acquisition of large amounts of data at particle physics laboratories. The chip contains First In First Out (FIFO) memory and five event memories, which are triggered externally • development and production of a 14-channel, 10 bit A/D converter running at 80 MHz. The chip area is 16 mm2. ASIC Design ASICs must be extremely well designed or have as their basis a tried and trusted system before committing them to silicon as it is a very expensive process. The ASIC contains functional blocks which can be interconnected at silicon level. These are known as a semi-custom device. Alternatively, the whole device can be designed from scratch as in the case of the custom or full-custom chip. ASICs are manufactured to a customer’s specification. The customer tells the design house what is required. DET: Mechatronic Systems: An Introduction (Higher) 37 Microcontrollers What is a microcontroller? A microcontroller is by nature, of the ASIC type. It is a System On Chip as explained above. All microcontrollers have at their heart a microprocessor (CPU), which will have RAM/ROM and I/O interfacing in one form or another. They will also have some, but not necessarily all of the following:- A/D Converters, D/A Converters, timers, serial interfaces, parallel interfaces, watchdog timers, oscillators, Pulse Width Modulators. The needs of embedded control The needs of embedded control are very different from those of the standard personal computers. For the life of the device, usually it will run only one program, apart for the occasional program update. Because there is little support hardware; VDU, keyboard, hard-drive or floppy disk there is little need for mass storage. Manmachine, machine-man interaction is also limited. They are often required to operate in hostile environments such as high temperatures, dust/corrosive atmospheres and perhaps both mechanically and electrically noisy. The main features of a microcontroller system can be seen in the simplified diagram below: RAM program memory PROGRAM COUNTER Arithmetic Logic Unit ALU clock ROM program memory I/O ports 'Real' world timers Simplified diagram of a microcontroller 4 Microcontrollers contain all the features within a single package, as opposed to the microprocessor system where each block in the diagram above is normally a separate integrated circuit. In general the only component that needs to be added to a microcontroller is a clock circuit, this can take the format of either a ceramic resonator or a quartz crystal. To give you a feeling for the characteristics and architecture of the microcontroller Let us examine a microcontroller that has been designed especially for use in Higher Still courses, the Basic Stamp microcontroller. 4 Higher Still Technological Studies: System and Control DET: Mechatronic Systems: An Introduction (Higher) 38 The Basic Stamp microcontroller In industry microcontroller programs are normally developed using an ‘assembly’ or ‘C’ programming language. Unfortunately these languages are not particularly easy for the beginner to understand and it can take a great deal of time and study before a programmer is skilled enough to construct a complex program. For this reason it is easier for the beginner to program with ‘user-friendly’ languages such as BASIC (Beginners All-Purpose Symbolic Instruction Code). This language is specifically designed to be ‘easily understood’ and so primarily uses standard ‘English language’ words as instructions. However, before the microcontroller can understand the BASIC instructions, these instructions must be processed by an interpreter into machine code. The extra processing time involved in the conversion results in a BASIC program running slower than an equivalent machine code program. On the good side, a microcontroller can process over one million assembler instructions a second, so the extra processing required by the BASIC interpreter is negligible in most cases. BASIC Stamp Vin +5V 7 6 5 4 3 2 1 0 GND The original Parallax Basic Stamp The original Parallax Basic Stamp The ‘Basic Stamp’ system was developed in the early 1990s (by Parallax Inc., USA) to enable design engineers to quickly prototype systems using microcontrollers by programming in a modified BASIC language (called PBASIC – short for Parallax BASIC) rather than assembler or C. The Basic Stamp system is an ideal compromise for rapid prototyping – all the power and versatility of a microcontroller combined with a simple programming language. The original Parallax Basic Stamp module consisted of a small printed circuit board with battery clip and prototyping area, see the figure above. Although suitable for prototyping work, this module is not so appropriate for laboratory exercises, and so the Stamp Controller has been developed for educational use. This uses identical ‘chips’ to the original module, but is configured on a larger printed circuit board with all the necessary connectors etc. This can be seen below: The Higher Still-developed Basic Stamp Controller For more information on the Higher Still-developed Basic Stamp Controller, please refer to Outcome 3 Microcontrolled Mechatronic Systems Student notes section of the Higher Still Technological Studies support notes. DET: Mechatronic Systems: An Introduction (Higher) 39 COMPUTER LINK V+ 0 1 2 3 POWER BROWN OUT REGULATOR EEPROM MICROCONTROLLER 0V 7 6 5 4 RESET CLOCK V+ 0V INPUT OUTPUT 4 MHz 0 1 2 3 4 5 6 7 0 V V+ V+ V+ 0 0 7 7 1 1 6 6 2 2 5 5 3 3 4 0V 4 0V STAMP CONTROLLER (C) REVOLUTION EDUCATION The Higher Still-developed Basic Stamp Microcontroller DET: Mechatronic Systems: An Introduction (Higher) 40 In order that you get a balanced introduction to microcontrollers, the following two Intel microcontroller examples show their diversity: Intel 8XC196MC Industrial Motor Control Microcontroller Specifications: • • 16 Kbytes of on chip ROM • • High performance CHMOS 16-bit CPU 488 bytes of on-chip RAM Up to 53 I/O lines • • • Event Processor Array • • Two 16 bit timers • • 13 channel 8/10 bit A/D with sample / • hold with zero offset adjustment • Flexible 8/16 bit external bus • 3 µS 32/16 divide Register to register architecture Peripheral Transaction Server (PTS) with 11 prioritised sources (EPA) – 4 high-speed capture/compare modules -- 4 highspeed compare modules 3-phase complementary waveform generator 14 prioritised interrupt sources • • 1.75 µS 16 x 16 multiply Idle and power down modes Architecture: VREF ANGND NMI 16 CPU A/D CONVERTER 488 BYTE REGISTER FILE MICROCODE ENGINE S/H MUX 16K ON-CHIP ROM/OTPROM (OPTIONAL) INTERRUPT CONTROLLER ALU PERIPHERAL TRANSACTION SERVER MEMORY CONTROLLER 8 QUEUE 16 TIMER 0 TIMER 1 PORT 0-1 A/D PORT 0-1 EVENT PROCESSOR ARRAY 2 PWM PORT 3 ADDR/DATA BUS PORT 4 3-PHASE WAVEEFORM GENERATOR PORT O/1 PORT O/1 EPA PORT 2 PORT 6 PORT 5 CONTROL SIGNALS WATCHDOG TIMER EXTINT Intel 8XC196MC Industrial Motor Control Microcontroller DET: Mechatronic Systems: An Introduction (Higher) 41 Intel Automotive 80C31BH/80C51BH/87C51 Microcontroller Specifications • High performance CHMOS processor • Extended automotive temperature range (-40 to 125OC) Power control mode • 4K byte on-chip ROM/EPROM • 128 x 8-bit RAM • 32 programmable I/O lines • Two 16-bit timer/counters • 5 interrupt sources • Quick-pulse EPROM programming • • Boolean processor • 2 level program memory lock EPROM Programmable serial port • TTL and CMOS compatible logic level • 64K external data memory space • Idle and power down modes RAM ADDR. REGISTER • RAM PORT 0 DRIVERS PORT 2 DRIVERS PORT 0 LATCH PORT 2 LATCH EPROM ROM PROGRAM ADDR REGISTER ACC B REGISTER TMP 2 TIMING AND CONTROL ALE EA RST INSTRUCTION REGISTER ALU PSEN OSC. XTAL 1 BUFFER TMP 2 INTERRUPT, SERIAL PORT, AND TIMER BLOCKS PC INCREMENTER PROGRAM COUNTER PSW DPTR PORT 1 LATCH PORT 3 LATCH PORT 1 DRIVERS PORT 3 DRIVERS XTAL 2 Intel Automotive 80C31BH/80C51BH/87C51 Microcontroller DET: Mechatronic Systems: An Introduction (Higher) 42 As you can see from the previous pages microcontrollers are varied in the way they are put together. It is entirely possible to pick up an ‘off the shelf’ microcontroller for just about any system. This, their size, their relative cost and their availabilty makes them ideal for embedding in control systems which require little if no interference or maintenance. In the first Intel example the microcontroller has been designed specifically to deal with an industry wide problem, the control of an AC motor. Motor control can be carried out using discrete electronic circuitry but with this device fewer components means less chance of circuit failure. A 3-phase waveform generator is included on chip to be used in conjunction with an ‘inverter’ driver, which is a special arrangement of diodes. The device comes in either a 64 pin format or in the 84 lead package. The second example is an 8-bit microcontroller designed specifically for the automotive area. The device comes in either a 40-pin or in a 44 pin package. There are many other microcontroller manufacturers producing devices for an everwidening number of diverse applications. Programmable Logic Controllers PLC’s What is a Programmable Logic Controller? The Programmable Logic Controller (PLC) is a device, which was developed to replace sequential relay circuits employed for plant control. The PLC operates by examining the state of all inputs and depending upon their status, changing the outputs to reflect the needs of the system. PLC’s are employed in many ‘real world’ applications and are widely employed in industrial locations. Machining, packaging, material handling, automated assembly and many other situations. Just about any application that needs electrical control could employ a PLC. Control Bus Address Bus Data Bus CPU INPUT/ OUTPUT MEMORY CLOCK External/Internal Bus Interface The PLC consists of a Central Processing Unit (CPU), an area of memory and an area to handle inputs and outputs. The PLC can be considered to be a box full of hundreds or even thousands of separate relays, counters, timers and data storage locations. These counters, timers etc. do not physically exist but rather they are simulated and can be seen as software counters, timers etc. INPUT MODULE OUTPUT MODULE PROGRAM INPUT PLC Architecture DET: Mechatronic Systems: An Introduction (Higher) 43 PLC Central Processing Unit (CPU) The Central Processing Unit controls and processes all of the operations within the PLC. In order that the CPU can organise the timing synchronising of these internal operations, a clock signal is required. This clock signal is generally between 1 and 8 MHz, in fact it is this frequency that determines the operating speed of the PLC. PLC Memory As with previous devices examined the PLC requires two types of memory. ROM; for storage of permanent program information, data and operating system. RAM; for storage of user programs and input/output buffering for dynamic data. As previously discussed ROM memory is classed as non-volatile and RAM is classed as volatile, although the RAM may have an appropriate battery back up in order to protect system integrity when power is removed from the unit. Another form of memory also used within the PLC is Electrically Erasable Programmable Read Only Memory (EEPROM) which allows the user to replace the code held on this type of ROM. This allows the user program to be downloaded and held permanently on the PLC. Another good reason for EEPROM is that the system then becomes very flexible, programs can be written well away from the system, downloaded onto an EEPROM chip taken to the system and the EEPROMs can be swapped without the need for a programmer to be present. PLC Input/Output The input/output modules provide the signal conditioning and isolation that allow sensors and actuators to be connected directly to the PLC. Larger PLC’s allow for a variety of input and output voltage and current configurations. Common input voltages are 5V (TTL) and 24V (standard signal voltage). Common output voltages are 24V and 240V often specified as transistor, relay or triac type. Relay outputs are able to switch currents of around 2 amps, but are relatively slow. Transistor outputs allow faster switching than relays. Triac outputs allow control of AC devices. Optoisolators allow for isolation in both the transistor and triac outputs. PLC Programming Languages With PLCs, there is more than one way to program them. This can be carried out either by hand held programmer or download directly from a PC. There also exists more than one type of programming language. Some of these languages are as follows: • statement listing • matrix programming • ladder logic. The latter, ladder logic, is by far the most commonly used program language, but each PLC manufacturer tends to use their own dialect. The Higher Still Mechatronics unit uses a PLC simulator to provide information. A demonstration version of this simulator can be found at: http://www.bytronic.com DET: Mechatronic Systems: An Introduction (Higher) 44 Ladder Logic What is ladder logic? It is the graphical representation of how the system should react to changes at both its inputs and its outputs. The graphic symbols usually used are as follows: Input rung of the ladder logic program Output rung of the ladder logic program or Normally Open Input Equivalent switch schematic Normally Closed Input Equivalent switch schematic Output Devices The LOGIC in ladder logic programs is implemented in the way these inputs and output symbols are connected. Below is a single rung of a ladder logic program. In 1 In 2 out 1 Simple (one rung) Ladder Logic Program (and function) The way the inputs are connected determines the logic of the rung. In the example above In 1 is ANDed with In 2. In the example below In 1 is ORed with In 2. In 1 out 1 In 2 Simple (one rung) Ladder Logic Program (or function) The PLC has evolved to deal with digital switching but can be used to carry out analogue control provided the correct analogue units have been added to the system. These modules, usually provided by the same manufactured, allow the PLC to stay a very flexible device. A minimal system usually forms the basis for a control problem and extra modules are added as your system’s requirement grows. For more information about program writing in ladder logic and using LadSIM and the ladder logic simulation program see the Programmable Controlled Systems (D147 12) Support notes. DET: Mechatronic Systems: An Introduction (Higher) 45 Controller Types Reviewed Just to wind things up let’s review the controller types examined: PC-based Widely available and can carry out both Analogue and Digital control, (requires the addition of the correct I/O card, uses memory for storage of the current measured values and the program. Has the advantage of massive processing power: Useful where image recognition is required or any other number crunching process) Embedded controller Widely employed where there is no need, or room, for a full-blown PC. (Can be a chopped version of the standard PC or a custom built ASIC or a microcontroller based system) Microcontroller Widely employed in many household, automotive and industrial devices. (Usually on a single chip and consists of a single microprocessor with built in analogue and digital interfacing capability along with program storage area, memory, support chips and circuitry) Programmable Logic Controllers Widely used in industry to control automated systems. (Consists of a microprocessor, memory, solid state switches (relays) and can also be capable of analogue and mathematical functions, usually by way of add on modules). Hardwired Logic Was once widely employed in many household, automotive and industrial devices. (Usually on a printed circuit board it has no microprocessor or built in analogue and digital interfacing capability. The circuits are individually designed for specific tasks and require a complete re-design, test and re-build, in order to control a new system). DET: Mechatronic Systems: An Introduction (Higher) 46 PROGRAMMING There are many different ways of visualising the internal architecture of the microprocessor. In the early days, computers were programmed by setting switches and by using patch leads (this was the program). We have evolved since the days of toggle switches and patch leads and now have these wonderful things called programming languages. Without going into too much theory of computer science, the PC sitting on your desk cannot, and never will be able to directly understand any word you care to say to it. If you could open it up, apply your fingers to the internal tracks on the circuit board, and tap out an electronic rhythm of 1s and 0s, then you might be approaching something that could be called PC communication. Writing computer programs this way would be tedious, error prone, and in reality virtually impossible. Traditionally programming languages have been divided into two forms, interpreted and compiled. Interpreted languages have a reputation for isolating their users from the system, shielding them from the harsh realities of computer use and generally giving them a very soft introduction to programming. Interpreted languages allocate the memory requirements without the users knowledge. They also tend to be a lot slower and a lot less slick than their compiled counterparts. The reason for this latter point is simple. The interpreter adds code overheads which are extra to the program. This makes the resulting machine code less efficient than a version specifically tailored for the processor’s architecture. Compiled Languages A computer compiler takes your instructions and keywords (programs) and translates them into the electronic 1s and 0s that the computer needs in order to be able to go and do what you want it to do. The original program is called the source program, sometimes referred to as the source code. The machine language form of this program, after compilation, is called the object code. Once it has been translated into object code, it is linked with small, standard procedure programs called library routines. It is these library routines that have made compiled languages like C so popular due to the ability to selectively include library files for different processor types, thus allowing cross platform compilation. Compiled languages execute faster than interpreted programs, as they do not have the burden of the underlying interpreter. Programmers using compiled language must have a much better understanding of the memory requirements for their programs as compilers leave this entirely up to the user. DET: Mechatronic Systems: An Introduction (Higher) 47 Interpreted Languages An interpreted program, on the other hand, does not immediately do what you want it to do. It needs a program that sits in between the machine and your program. When you run your program you are really running the interpreter which then happily plods through your code one line at a time, transferring translated, interpreted statements to the computer in a format it understands. It's a slow process, like talking to someone through an interpreter. Interpreted languages can alerts users to errors in statements at time of execution. Interpreted languages also allow the user to execute a single statement before it is included in the program. This difference in languages is generally categorised into High-Level and Low-Level Languages Low-level languages (first and second-generation languages) provide binary instructions for the computer to execute: these are known as machine languages. High-level languages (third-generation languages) use English-like instructions that cause the computer to carry out binary commands. They work at the level of the programmer rather than at the level of the machine. Low-Level Computer Languages Machine Language (1st Generation Languages) Expressed in binary, octal, or hexadecimal codes Depends on the processor type Assembly Language (2nd Generation Languages) Expressed in abbreviations of commands: (mnemonics) Depends on the processor type User has complete control over the computers operations. Executes faster than high level High-Level Computer Languages FORTRAN FORmula TRANslator. First high-level language, released in 1956. Designed for scientific, mathematical, and engineering applications: Compiled language - once compiled, extremely fast execution. BASIC Beginners All-purpose Symbolic Instruction Code. Designed to be easy to learn, yet retain the formula translation characteristics of FORTRAN. First used in 1964. Current versions are much more powerful than early, simpler versions. Very popular on personal computers. Interpreted language, but compilers are available. DET: Mechatronic Systems: An Introduction (Higher) 48 Pascal Developed as a teaching language. First released in 1971. Programs must be written in a manner that meets accepted programming standards. Enforces structured programming. Now used for commercial applications as well as for teaching. Most versions are compiled, but an interpreted version is available. C Developed at Bell Labs in 1974. Produces machine-language code that executes extremely fast. Allows a high degree of control over the machine. Easily portable among computers and operating systems. Many commercial programs are written in C. Compiled language. Very High-Level Languages Often known as fourth-generation languages (4GLs). Move the programmer even further away from the machine-code level than high-level or third-generation languages. They are usually nonprocedural - a user need write only what is to be done, not how. Natural Languages Natural languages are closer to everyday human languages. Natural languages excel at easy data access and are most commonly used to interact with databases. Object-Oriented Programming Use objects (self-contained items that combine data and algorithm) instead of structured programming. Object-oriented programming languages: Smalltalk C++ Turbo Pascal Your choice of programming languages should not be based solely on the ease of a language to learn, however. You should also think carefully about the sort of tasks you are likely to want your programs to perform. As noted, Perl is very well suited for text manipulations and related tasks, but C would probably be preferred for a program that needs to do a good deal of ‘number crunching’. DET: Mechatronic Systems: An Introduction (Higher) 49