Overview of Mechatronic Systems Contents: 1. Introduction to

advertisement

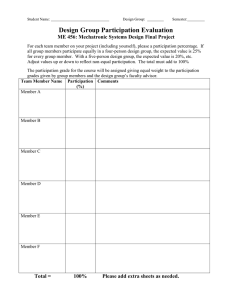

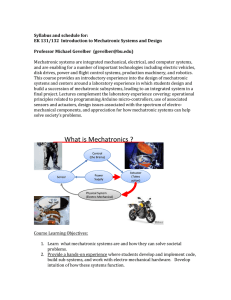

Overview of Mechatronic Systems Contents: 1. Introduction to Mechatronics 2. Diagrammatic view of a Mechatronic system 3. Example of a Mechatronic system 4. General Design process 5. Summary 1. Introduction to Mechatronics: Mechatronics is defined as the interdisciplinary field of engineering that deals with the design of products whose function relies on the integration of mechanical, electrical, and electronic components connected by a control scheme. Examples: figure 1: Mechatronic devices? What do these devices have in common? A mechatronic device is one that is able to perceive the surrounding environment, make appropriate decisions based on that information, and execute those decisions (take action) Perceive the environment Sensors Controller Make Decisions Actuators Take Action Figure 2: 2. Diagram of a Mechatronic System: Mechanical System Sensors Or “plant” Measurement Signal Interface -filters -ATD -amplifiers, etc. Actuators Controller: MCU (or other PC, PLC, etc) Output Signal Interface - amplify power of signals - condition Output Display - leds, crt, buzzer - Contains control algorithm, decision making, control theory, etc. Data Storage/ Retrieval Figure 3: Diagram of a Mechatronic System Figure 3 provides insight into the design process for a mechatronic (M) system: 1) Select elements in each of the areas 2) Model/Analyze/characterize behavior of the elements 3) Account for interactions between modules One technique to represent and model an M system is as a block diagram. Block diagrams range from symbolic to mathematic in representation. Block diagrams serve as a starting point in the design of the system. They also serve as tools to build mathematical models that can simulate the behavior of the system. Simulink (Matlab) is a tool that was specifically created to simulate such systems in block diagram form. First, consider a general M system in symbolic blockdiagram form. 1) Open loop system: Input controller actuator Figure 4: Open loop block diagram Plant Output 2) Closed-loop system: Desired behavior Controller Desired output Operational, logic controller compare Actual output Control alg. Actuators Measure Plant Sensors Output behavior Feedback Figure 5: closed-loop block diagram This represents a general representation for the class of M systems. Now consider a specific instance of this class: for example a four degree-of-freedom SCARA robot: 3. Example of a Mechatronic System: The SCARA Manipulator The SCARA manipulator can be represented in the following block diagram form: Controller + Desired output Desired behavior θ1 PID ctrl - - Planning, velocity kins. Motor 1 Joint 1 Encoder 1 θ2 Forward / Inverse Kinematics, Path Driver 1 PID ctrl Driver 2 Motor 2 Joint 2 Tool pose Encoder 2 θ3 - PID ctrl Driver 3 Motor 3 Joint 3 Encoder 3 θ4 - PID ctrl Driver4 Motor 4 Joint 4 Encoder 4 Figure 6: Block diagram for a SCARA robot This provides a representation of the SCARA at an early stage of the design process. Discuss the information that exists in this block diagram. What information is not here? 4. Design Process/ Evolution of a Mechatronic System: The general steps in the design process of developing a Mechatronic system will be demonstrated here. This process will start with a form of the system (a SCARA robot). 1) Develop a high-level diagram of the necessary system components: Much like figure 6 above, this will show actuators, sensors, controller, mechanical system, and their relationship. Figure 7 gives an example for 1 dof of the SCARA manipulator: Controller + Desired output Desired behavior θ1 - PID ctrl Driver 1 Motor 1 Joint 1 Encoder 1 Forward / Inverse Kinematics, Path Tool pose Planning, velocity kins. Figure 7: Block diagram for a SCARA robot 2) Specify each of these elements in greater detail: Select specific components for each. This stage requires: 1) knowledge of the necessary requirements for each block 2) knowledge of various Commercial-off-the-shelf (COTS) components that are available 3) Input and output requirements for each As these decisions are made, the mechatronic system can be represented in greater detail in the block diagram. This is shown in Fig. 8 for the SCARA. controller MHC12 Desired output Desired behavior + - θ1 PID ctrl Forward / Inverse Kinematics, Path Driver 1: AMC 50A8t Motor 1 Maxon DC 2260.88573.216 Interface HPCTL 2020 16 counter Planning, velocity kins. Gear train 50:1 3stage planetary 500 PPR Optical Inc. encoder HEDS 500 Joint 1 Revolute, brg type Tool pose Figure 8: Block diagram for a SCARA robot showing component selection 3) At this stage in the design process, interaction of the various components should be considered. This consideration should include: 1) input and output types a. Analog/DC b. Incremental, absolute c. etc. 2) Power requirements 3) Impedence 4) Signal power Figure 9 shows in a general form how the block elements communicate with each other. Contro MHC12 + Desired output Desired behavior Forward / Inverse Kinematics, Path Planning, velocity kins. θ1 - PID ctrl Driver 1: AMC 50A8t Motor 1 Maxon DC 2260.88573.216 Interface HPCTL 2020 16 counter Gear train 50:1 3stage planetary 500 PPR Optical Inc. encoder HEDS 500 Joint 1 Revolute, brg type Tool pose Figure 9: Block diagram for a SCARA robot showing component interaction 4) As the design process progresses, the behavior of the system should be modeled for analysis and simulation purposes. This can be used to: 1) Design controller 2) Determine motor requirements 3) Determine power requirements 4) Evaluate system performance 5) Determine driver requirements 6) etc. A system model is developed based on inserting specific models for the various block elements into the block diagram. This process is shown in Fig. 10 for one axis of the SCARA manipulator: Controller e + - Vpow Vref * k * kds * ki /s Gain + 1 - Ls+R i T kt θ_dot 1 1 2 s (Ja +GR Jg)s+C θ Kb Figure 10: System model for one axis of the SCARA In the block diagram, these are shown in Laplace (or “s”) space. Remember that this is a handy technique to represent differential equations as algebraic equations. More on this later. 5) Complete the design of the elements in the system (Mechanical, electrical, controller code). Update the system framework as necessary 6) Develop system prototype for testing, evaluation purposes. This stage will show how well you have prepared your system design. A good designer will expect a few flaws to show up in the design during the testing process. However, at this stage it is far more expensive to fix major design/analysis errors than any other point. (That is not completely true, it is even more expensive to fix an error after the product is sent to market). 5. Summary This outline has provided a brief introduction to mechatronic systems and the general design process. Every mechatronic product is unique in function and form. Yet they all share a common structure when viewed in component function form (Fig. 3). The design process then involves the selection, design and integration of the elements that form these parts of the mechatronic system. The Tool pose general design process is demonstrated for a SCARA manipulator. The block diagram provides a useful tool to organize a mechatronic system and the overall design process.