How to select varistors

advertisement

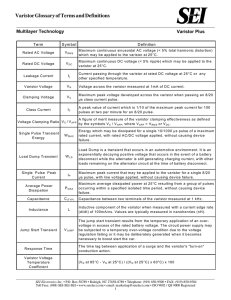

HOW TO SELECT VARISTORS We have three alternatives: - selection of the varistors suitable for the operating voltage of the application - calculating the surge current, energy absorption and average power dissipation - the maximum possible voltage rise in case of overvoltage at the selected varistor we compare then with the electric strength of the component or circuit to be protected. 1ST STEP To get the lowest possible protection level you should select a varistor type with a voltage rating which is adequate to the operating voltage of your application or lies only slightly above. You should also count on a possible increase in operating voltage, that is at least 10% on supply lines. You can select varistors with higher operating voltage ratings as well, especially when an extremely low leakage current is more important than the lowest protection level possible. 2ND STEP As soon as we stated the maximum operating voltage, we've reduced the number of appropriate varistors to a maximum of 8 types - at 220 V ac, the 8 types of V250 (V250K5 V250S40). Now we need to define the loading which the varistor is to withstand. Then we must compare those values with the maximum permissible values, which are specified in our catalogue. We can select any varistor having ratings for maximum surge current, energy absorption and average power dissipation that lie above the values determined for our application. To avoid ambiguity in assignments of the circuit data and the varistor data we should make the following distinction: - maximum possible load values of the varistor, which result from the electrical specifications of the environment - identification marked with " ′ " - maximum permissible ratings of the varistor which are limited by its surge current and energy absorption handling capability - identification marked with "max" The above stated we can see also from the following designations: i′ ≤ imax W′ ≤ Wmax P′ ≤ Pmax When estimating the load values of a varistor we should assume the worst case condition that the varistor has to absorb the entire stored energy 1 2 L i 2 of a switched-off coil. In this way we will always include an additional safety margin owing to losses in the other components of the circuit. 2.1 SURGE CURRENT The maximum surge current value of the varistor depends on the pulse width and the required number of repetitions. It can be taken from the derating curves, allowing for these two parameters. The maximum possible surge current value we use then as basis for comparison. The deratings specify maximum values for rectangular surge current waves. To enable the comparison with these maximum ratings, we should convert the actual surge current wave of any shape to an adequate rectangular wave. The easiest method is to use the graphical rectangle method shown below. Figure 1. At the peak value the surge current wave converts to a rectangle of equal area. tR is the duration of the equivalent rectangular wave and is the same as the pulse width in the derating curves. We need the period T for calculating the average power dissipation resulting from periodic energy input. We could then conclude that it is the surge current which is required for selection and not the surge voltage wave causing this current. The very low internal impedance of supply lines at operating frequency is very often used, incorrectly, to calculate the current's amplitude for travelling waves on power and transmission lines. At frequencies in the kHz and MHz range the greater characteristic impedance of the line determines the ratio of surge voltage to current. 1000 Ω 100 Z 10 1 0,01 0,1 1 f 10 MHz 100 Figure 2. In the graph above you can see the typical values for a supply line. 2.2 ENERGY ABSORPTION Energy absorption is associated with a surge current flowing through the varistor: t1 ∫ v (t )i (t )dt t0 We can solve this integral in graphical form by conversion to an equivalent rectangular current and voltage function. If we have made the determination of the current (flowing through the varistor) with a storage oscilloscope and the conversion to an equivalent rectangle, then we can determine the energy absorption of the varistor by multiplication with the maximum voltage drop v′ occurring at the varistor: W′ = v′ i′ tR [ J] v′ [V] i′ [ A] tR [ A] v′ - taken from the corresponding V/I curve as the value related to i′ or - it can be determined by oscilloscope as the maximum voltage drop at the varistor. If the overvoltages result from switching off inductors, the "worst-case" principle can also be used for calculating the required energy handling capability of the varistor. The value of the absorbed energy cannot be greater than the energy stored in the inductor: W′ = 1/2 L i′ [J] L [H] i′ [A] You should always include a safety margin owing to losses in other components of the circuit to be protected. The duration of free-running processes (when switching off inductors) lie generally in the range of milliseconds. The energy values determined on the basis of equation can be compared with adequate accuracy with 2 ms tabulated values of the standard table in our catalogue ; since, in this case, the maximum absorption of the varistors is almost independent of the energy input time. The above described comparison of energy values means that it is not necessary to determine the surge current and pulse width in accordance with 2.1 SURGE CURRENT 2.3 POWER DISSIPATION If we have determined the varistors according to the previous steps, then the power dissipation, resulting from the applied operating voltage, is negligibly low. If varistors absorb energy periodically, it is subject to the average power dissipation: P′ = W ′ v ′ i ′ tr = T T [W ] T [s] = cycle time E is the value of an individual absorption cycle - calculated on the basis of the rectangle method. According to the figure 1, T means the cycle time. By solving this equation for T, it is possible to calculate the minimum time, which must elapse prior to a renewed energy absorption without exceeding the maximum average power dissipation of the varistor: T min = W′ P max [s ] Metal oxide varistors are less suitable for "static" continuous loading - voltage stabilisation. For this purpose we should use components developed for continuous duty (Z diodes). 3RD STEP The maximum possible voltage rise in the event of an overvoltage can be checked with the aid of the V/I characteristics. The value can be read off directly (for the most unfavourable position of the varistor in the tolerance field) if the surge current is known. In case that the determined voltage value exceeds the electric strength of the components to be protected, we have those possibilities available (in order to lower the protection level): - Dispensing with the safety margin to a certain extent Example: For work at 220 V ac line voltage, choose varistors "V230" instead of "V250" - Improved matching to the operating voltage by series connection Example: 320 V ac line voltage + 10% results in approximately 350 V ac. In this case, we should select varistor type V385. However, if two varistors of type V175 are connected in series, this produces the behaviour of a V350 type with a 35 V lower protection level. - Selection of a closer tolerance field We select, for example, a special type which utilises only the lower half of the standard tolerance field. This reduces the protection level by 10%.