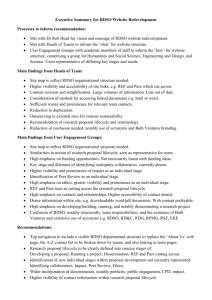

CORRIGENDUM Schedules with specifications Name of the Work

advertisement

CORRIGENDUM Schedules with specifications Name of the Work:- Provision of reliability improvement of signaling and telecom equipments in Trichchirapalli – Pudukottai, Manamadurai – Rameswaram, and Pudukottai – Manamadurai sections in Madurai Division Sl. Description Unit Total No. 1 Supply and Installation of earth electrode as per Nos. 42 RDSO/SPN/TC/75/2008, consists of (a) Earth electrode 1.2m x 1.2m x 0.003m – 40Kg Copper plate (b) Earth conductor 25 x 3mm (15mts) – 10.5Kg Copper strip (c ) HDPE pipe 75mm x 4mm thick – 3mts (d) MS angle (50mm x 50mm x 3mm) – 21Kg (e) LS for concrete slab, Cement concrete chamber & G.I. cover with handle of rigid to G.I. frame – LS 2 Supply of OBO make class D surge protective devices (SPD) Nos. 41 for handling switching surges of 8/20 µs as per RDSO/SPN/165/2006 3 4 Supply of OBO make class B&C surge protective devices Nos. (SPD) for handling switching surges of 10/350 µs and 8/20 µs as per RDSO/SPN/165/2006 consisting of a. MCD-50B OS – 1 No. b. MCD-125B/NPE-1 No. c. V20-C/1 FS-1 No. d. Prewired with imported Redoing the joints as per RDSO Specn. TC-77-2010 Rev.2 :- ( Existing joints to be opened and rejoined with new kits.) (a) Derivation joints --Nos. The work involves the jointing of nominated quad using the Thermo shrinkable kit at a specified site marked by Railway Engineer. The miniature tapping transformer of 1120: 1120 ohms impedance used for tapping the quad has to be housed in the joint itself. The other end of the transformer shall be connected to 10P derivation cable laid already. While necessary precaution to be taken against moisture. The cable ends to be cleaned before jointing. All the materials required for the jointing including TSF jointing kit has to be arranged by the tenderer. (b) Straight through joints:The work involves the jointing of nominated quad using the Thermo shrinkable kit at a specified site marked by Railway Engineer. The work involves the opening of existing joints and rejointing the cable with new TSF kits. Necessary precaution to be taken against moisture. The cable ends to be cleaned before jointing. All the materials required for the jointing including TSF jointing kit has to be arranged by the tenderer. 8 35 Rate in Rs. Amount in Rs 5 6 (c) Loading coil joints:The work involves installation of loading joints using Thermo shrinkable jointing kits conforming to RDSO no: TC/29/81 suitable for 6quad jelly - filled cable. The loading coil shall be of miniature type of 88mH for 4 quads of the 6 quad cables. After jointing, the cable has to be tested for the insulation and continuity. If any defect is noticed the joint has to be redone by the contractor free of cost. All the materials required for the jointing including the TSF kit has to be arranged by the contractor. (d) Condenser joints :Balancing the cable and making condenser jointing (RDSO Spec. No. TC/11/73) for 6 quad cables. The values of the condensers are in the balancing schedule. . The condensers to be supplied by the contractor. CUM set will be provided by Railways. The materials required for balancing will be arranged by the contractor. Supply of Low maintenance secondary cells of the following capacities with necessary inspection as per specification/ drawing/ description enclosed in this document. c. Supply of secondary cells-2V-200AH capacity Nos. 275 Charging and installation of secondary cells of the following capacities, on existing battery stand/ RCC slabs in the battery room. The work involves charging of secondary cells, fixing and connecting the batteries with strips, manufacture and fixing of teakwood terminal box, termination of cables, wiring with suitable wire PVC 7/1 .40mm and 3/0.75mm copper through suitable PVC pipes/ casing properly clamped, provision of battery particulars board - 12mm thick plywood - teakwood finish with aliminium grooved channel frame, painting of battery particulars, and provision of hydrometer -1 No. on a stand and battery tester- 1 No. Charging of secondary cells shall be done by the contractor through reputed agencies. (Supply of secondary cells is not covered in this schedule). [Teakwood plank 25mm thick for manufacturing termination box with locking facility, wire PVC 7/1 .4mm and 3/0.75mm copper, anti-corrosive paint, varish, PVC pipes/ casing, and all other miscellaneous materials required for this work shall be supplied by the contractor]. c. Installation of 2V- 200 AH on existing stand/slabs 275 Per cell 7 Supply of Battery charger self regulating type suitable confirm Nos. to RDSO Spec. No. IRS.S.86/2000 with amendment latest 230V/24V/30A 9 8 Supply of Battery charger self regulating type suitable confirm Nos. to RDSO Spec. No. IRS.S.86/2000 with amendment latest 230V/24V/40A 16 9 Supply of Battery charger self regulating type suitable confirm Nos. to RDSO Spec. No. IRS.S.86/2000 with amendment latest 230V/110V/50A 10 10 Supply of BPAC spare cards for SCC-1 suitable for Model No. Nos. 710/A/P as per RDSO Specn No. RDSO/SPN/177/2005 or latest (CEL Make) 10 11 Supply of BPAC spare cards for SCC-2 suitable for Model No. Nos. 710/A/P as per RDSO Specn No. RDSO/SPN/177/2005 or latest (CEL Make) 10 12 Supply of BPAC spare cards for Modem card suitable for Nos. Model No. 710/A/P as per RDSO Specn No. RDSO/SPN/177/2005 or latest (CEL Make) 10 13 Supply of BPAC spare cards for Event logger suitable for Nos. Model No. 710/A/P as per RDSO Specn No. RDSO/SPN/177/2005 or latest (CEL Make) 10 14 Supply of BPAC spare cards for MLB-1 suitable for Model No. Nos. 710/A/P as per RDSO Specn No. RDSO/SPN/177/2005 or latest (CEL Make) 10 15 Supply of BPAC spare cards for MLB-2 suitable for Model No. Nos. 710/A/P as per RDSO Specn No. RDSO/SPN/177/2005 or latest (CEL Make) 10 16 Supply of BPAC spare cards for DC-DC converter card suitable Nos. for Model No. 710/A/P as per RDSO Specn No. RDSO/SPN/177/2005 or latest (CEL Make) 11 17 Supply of BPAC spare cards for Mother board card suitable for Nos. Model No. 710/A/P as per RDSO Specn No. RDSO/SPN/177/2005 or latest (CEL Make) 10 18 Supply of BPAC spare cards for Relay driver card suitable for Nos. Model No. 710/A/P as per RDSO Specn No. RDSO/SPN/177/2005 or latest (CEL Make) 10 19 Supply of Vital relay box with 24V Nos. Q series 1000 Ohms Nos. relay suitable for the BPAC Model No. 710/A/P as per RDSO Specn No. RDSO/SPN/177/2005 or latest (CEL Make) 10 20 Supply for DC-DC converter 24V/24V/1A as per RDSO Specn. Nos. No. IRS:S-96/2000 (CEL Make) 11 21 Supply of Tx coil and Rx coil 2 Nos. each suitable for the BPAC Model No. 710/A/P as per RDSO Specn No. RDSO/SPN/177/2005 or latest (CEL Make) Set 10 22 Supply of Reset Box suitable for the BPAC Model No. 710/A/P Nos. as per RDSO Specn No. RDSO/SPN/177/2005 or latest (CEL Make) 10 23 Supply of Inverter 110/110/1.5KVA as per RDSO Specn No. Nos. IRS:S-82/92 with Amendment-2 or latest 11 24 Supply of Voltage regulator Ferro resonant type 3KVA as per Nos. RDSO Specn No. IRS:S-74/89 with Amendment-6 or latest 14 25 Manufacture and installation of Electronic Digital Timer for Nos. Invetrer in the SM's Room with 30 minutes time delay circuit with a 10 minutes remaining alarm to remind SM's on duty to start the generator switch 'OFF'. The output of the Invetter/Inverters provided in the power room. The timer unit front panel should have the minutes and seconds digital counter, push switch, buzzer window and flasher indication to indicate the working condition as per the Block Diagram. The work includes wiring of relays in the power room, relay room and the timer unit in SM's room (Timer unit having sheet metal box of size 11"x6"x4") PCB with IC bulled electronic circuit, the work on 110V/AC/12VDC sensing voltage soldering materials, paint and all other miscellaneous materials required for the work shall be supplied by the supplier. Necessary spare cores between relay/battery room to SM's office with termination will be made available by Railway stations. Sections: ExTrichchirapalli Ex-Pudukottai, Ex-Manamadurai Remeswaram & Pudukottai - Manamadurai. Supply & installation of Relay Room opening detecting device Nos. (Model - Limit switch IS 13947-57 ML SR-S) This work includes, fixing of limit switch inside the relay room door and wiring to be made from NC & NO contacts of limit switch upto the datalogger wiring tag block duly using wire PVC 16 x 0.2mm copper wire from limit switch to tag block duly providing caping and casing. [Wire PVC 16/0.2mm copper, soldering materials, bunching threads, caping & casing and teakwood plank for fixing the device and all other miscellaneous materials required for the work shall be supplied by the Contractor]. Total 19 26 19