a

FEATURES

150 MSPS ENCODE Rate

Low Input Capacitance: 17 pF

Low Power: 750 mW

–5.2 V Single Supply

MIL-STD-883 Compliant Versions Available

APPLICATIONS

Radar Systems

Digital Oscilloscopes/ATE Equipment

Laser/Radar Warning Receivers

Digital Radio

Electronic Warfare (ECM, ECCM, ESM)

Communication/Signal Intelligence

High Speed 8-Bit

Monolithic A/D Converter

AD9002

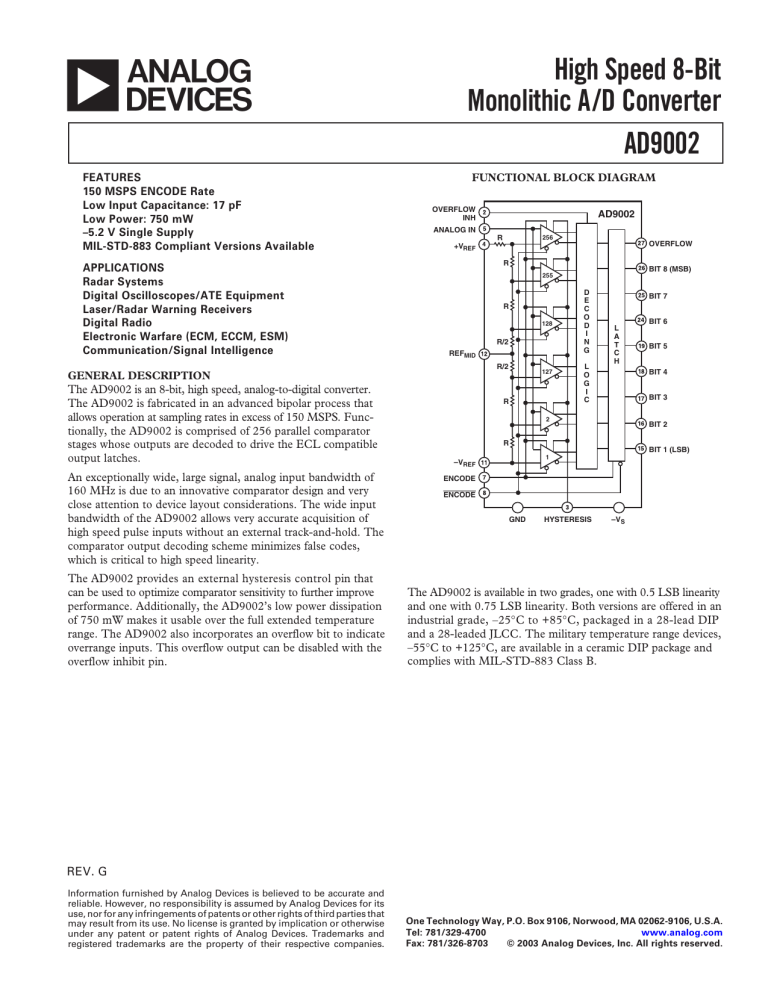

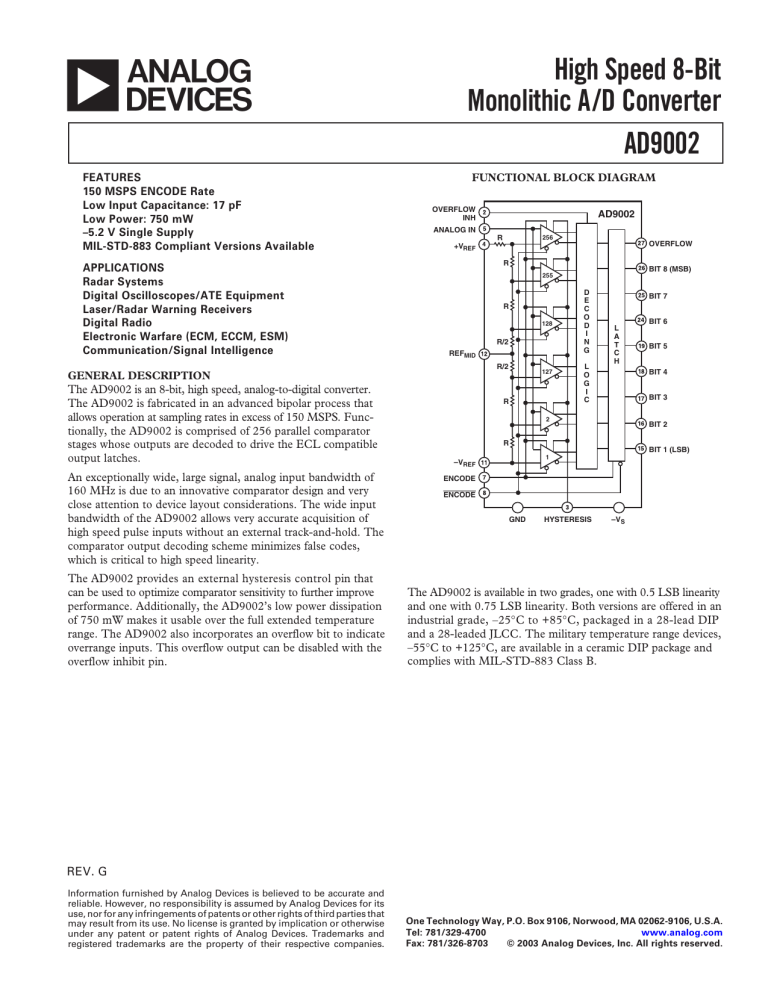

FUNCTIONAL BLOCK DIAGRAM

OVERFLOW

INH

AD9002

ANALOG IN

R

256

R

BIT 8 (MSB)

255

R

128

R/2

REFMID

R/2

127

GENERAL DESCRIPTION

The AD9002 is an 8-bit, high speed, analog-to-digital converter.

The AD9002 is fabricated in an advanced bipolar process that

allows operation at sampling rates in excess of 150 MSPS. Functionally, the AD9002 is comprised of 256 parallel comparator

stages whose outputs are decoded to drive the ECL compatible

output latches.

An exceptionally wide, large signal, analog input bandwidth of

160 MHz is due to an innovative comparator design and very

close attention to device layout considerations. The wide input

bandwidth of the AD9002 allows very accurate acquisition of

high speed pulse inputs without an external track-and-hold. The

comparator output decoding scheme minimizes false codes,

which is critical to high speed linearity.

The AD9002 provides an external hysteresis control pin that

can be used to optimize comparator sensitivity to further improve

performance. Additionally, the AD9002’s low power dissipation

of 750 mW makes it usable over the full extended temperature

range. The AD9002 also incorporates an overflow bit to indicate

overrange inputs. This overflow output can be disabled with the

overflow inhibit pin.

OVERFLOW

+VREF

R

D

E

C

O

D

I

N

G

L

O

G

I

C

BIT 7

L

A

T

C

H

BIT 6

BIT 5

BIT 4

BIT 3

2

BIT 2

R

BIT 1 (LSB)

1

–VREF

ENCODE

ENCODE

GND

HYSTERESIS

–VS

The AD9002 is available in two grades, one with 0.5 LSB linearity

and one with 0.75 LSB linearity. Both versions are offered in an

industrial grade, –25°C to +85°C, packaged in a 28-lead DIP

and a 28-leaded JLCC. The military temperature range devices,

–55°C to +125°C, are available in a ceramic DIP package and

complies with MIL-STD-883 Class B.

REV. G

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective companies.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700

www.analog.com

Fax: 781/326-8703

© 2003 Analog Devices, Inc. All rights reserved.

AD9002–SPECIFICATIONS

ELECTRICAL CHARACTERISTICS (–V = –5.2 V, Differential Reference Voltage = 2.0 V, unless otherwise noted.)

S

Parameter

Temp

RESOLUTION

DC ACCURACY

Differential Linearity

Integral Linearity

No Missing Codes

INITIAL OFFSET ERROR

Top of Reference Ladder

Bottom of Reference Ladder

Offset Drift Coefficient

ANALOG INPUT

Input Bias Current1

Input Resistance

Input Capacitance

Large Signal Bandwidth2

Input Slew Rate3

REFERENCE INPUT

Reference Ladder Resistance

Ladder Temperature Coefficient

Reference Input Bandwidth

25°C

Full

25°C

Full

Full

AD9002AD/AJ

Min

Typ

Max

AD9002BD/BJ

Min

Typ

Max

Min

8

8

8

0.6

0.6

Guaranteed

25°C

Full

25°C

Full

Full

25°C

Full

25°C

25°C

25°C

25°C

25°C

8

4

60

25

200

17

160

440

40

80

0.25

10

125

150

1.3

15

3.7

6

6

25°C

25°C

25°C

25°C

25°C

25°C

25°C

25°C

25°C

25°C

ENCODE INPUT

Logic “1” Voltage4

Logic “0” Voltage4

Logic “1” Current

Logic “0” Current

Input Capacitance

ENCODE Pulsewidth (Low)9

ENCODE Pulsewidth (High)9

Full

Full

Full

Full

25°C

25°C

25°C

OVERFLOW INHIBIT INPUT

0 V Input Current

Full

144

25°C

7.6

2.5

14

17

10

12

8

4

200

200

60

25

200

17

160

440

22

110

5.5

40

80

0.25

10

125

150

1.3

15

3.7

6

6

2.5

Full

Full

–1.1

25

110

5.5

200

17

160

440

40

80

0.25

10

125

150

1.3

15

3.7

6

6

2.5

48

300

46

1.5

200

200

750

50

0.8

NOTES

1

Measured with AIN = 0 V.

2

Measured by FFT analysis where fundamental is –3 dBc.

3

Input slew rate derived from rise time (10% to 90%) of full-scale input.

4

Outputs terminated through 100 Ω to –2 V.

5

Measured from ENCODE in to data out for LSB only.

6

For full-scale step input, 8-bit accuracy is attained in specified time.

7

Recovers to 8-bit accuracy in specified time after 150% full-scale input overvoltage.

8

Output time skew includes high-to-low and low-to-high transitions as well as

60

25

22

110

5.5

1.5

200

200

µA

µA

kΩ

pF

MHz

V/µs

200

17

160

440

40

80

0.25

10

125

150

1.3

15

3.7

6

6

2.5

22

110

5.5

3.0

2.5

0.6

–1.5

150

120

3

300

55

50

44

47.6

60

144

48

46

–1.1

175

200

mV

mV

mV

mV

µV/°C

1.5

1.5

300

750

50

0.8

175

200

1.5

MSPS

ns

ps

ns

ns

ns

ns

ns

ns

V

V

µA

µA

pF

ns

ns

µA

Bits

55

50

44

47.6

60

dB

dB

dB

dB

dB

–1.5

145

Ω

Ω/°C

MHz

7.6

–1.1

–1.5

145

14

17

10

12

–1.1

144

48

LSB

LSB

LSB

LSB

20

7.6

–1.1

–1.5

4

3

55

50

44

47.6

60

46

8

–1.5

150

120

7.6

175

200

14

17

10

12

–1.1

144

0.5

0.75

0.5

1.2

Guaranteed

1.5

1.5

300

0.4

0.6

–1.5

150

120

Unit

Bits

3.0

2.5

3

55

50

44

47.6

60

750

50

0.8

60

22

1.5

1.5

145

4

200

200

AD9002TD

Typ

Max

0.4

20

–1.1

3

DIGITAL OUTPUTS4

Logic “1” Voltage

Logic “0” Voltage

8

0.6

1.5

1.5

0.75

1.0

1.0

1.2

Guaranteed

3.0

2.5

–1.5

150

120

46

0.6

14

17

10

12

Min

8

0.6

20

–1.1

48

0.5

0.75

0.5

1.2

Guaranteed

0.6

25°C

25°C

25°C

25°C

25°C

Nominal Power Dissipation

Reference Ladder Dissipation

Power Supply Rejection Ratio15

0.4

3.0

2.5

AC LINEARITY10

Effective Bits11

In-Band Harmonics

DC to 1.23 MHz

DC to 9.3 MHz

DC to 19.3 MHz

Signal-to-Noise Ratio12

Two Tone Intermod Rejection13

25°C

Full

25°C

25°C

25°C

0.4

20

DYNAMIC PERFORMANCE

Conversion Rate

Aperture Delay

Aperture Uncertainty (Jitter)

Output Delay (tPD)4, 5

Transient Response6

Overvoltage Recovery Time7

Output Rise Time4

Output Fall Time4

Output Time Skew4, 8

POWER SUPPLY14

Supply Current (–5.2 V)

0.75

1.0

1.0

1.2

AD9002SD

Typ

Max

–1.5

145

750

50

0.8

175

200

1.5

V

V

mA

mA

mW

mW

mV/V

bit-to-bit time skew differences.

9

ENCODE signal rise/fall times should be less than 10 ns for normal operation.

10

Measured at 125 MSPS ENCODE rate.

11

Analog input frequency = 1.23 MHz.

12

RMS signal to rms noise, with 1.23 MHz analog input signal.

13

Input signals 1 V p-p @ 1.23 MHz and 1 V p-p @ 2.30 MHz.

14

Supplies should remain stable within ± 5% for normal operation.

15

Measured at –5.2 V ± 5%.

Specifications subject to change without notice.

–2–

REV. G

AD9002

ABSOLUTE MAXIMUM RATINGS 1

Supply Voltage (–VS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . –6 V

Analog-to-Digital Supply Voltage Differential . . . . . . . . 0.5 V

Analog Input Voltage . . . . . . . . . . . . . . . . . . . . –VS to +0.5 V

Digital Input Voltage . . . . . . . . . . . . . . . . . . . . . . . –VS to 0 V

Reference Input Voltage (+VREF, – VREF)2 . . . –3.5 V to +0.1 V

Differential Reference Voltage . . . . . . . . . . . . . . . . . . . . 2.1 V

Reference Midpoint Current . . . . . . . . . . . . . . . . . . . . ± 4 mA

ENCODE to ENCODE Differential Voltage . . . . . . . . . . . 4 V

Digital Output Current . . . . . . . . . . . . . . . . . . . . . . . . 20 mA

Operating Temperature Range

AD9002AD/BD/AJ/BJ . . . . . . . . . . . . . . . –25°C to +85°C

AD9002SD/TD . . . . . . . . . . . . . . . . . . . . –55°C to +125°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Junction Temperature3 . . . . . . . . . . . . . . . . . . . . . . . . 150°C

Lead Soldering Temperature (10 sec) . . . . . . . . . . . . . 300°C

NOTES

1

Absolute Maximum Ratings are limiting values, to be applied individually, and

beyond which the serviceability of the circuit may be impaired. Functional

operability under any of these conditions is not necessarily implied. Exposure to

absolute maximum rating conditions for extended periods of time may affect device

reliability.

2

+VREF ≥ –VREF under all circumstances.

3

Maximum junction temperature (T J max) should not exceed 175°C for ceramic

packages, and 150°C for plastic packages:

TJ = PD (θJA) + TA

= PD (θJC) + TC

where

PD = power dissipation

θJA = thermal impedance from junction to ambient (°C/W)

θJC = thermal impedance from junction to case (°C/W)

TA = ambient temperature (°C)

TC = case temperature (°C)

Typical thermal impedances are:

Ceramic DIP θJA = 56°C/W; θJC = 20°C/W

PLCC θJA = 60°C/W; θJC = 19°C/W

Recommended Operating Conditions

Input Voltage (V)

Parameter

Min

Nominal

Max

–VS

+VREF

–VREF

Analog Input

–5.46

–VREF

–2.1

–VREF

–5.20

0.0

–2.0

–4.94

+0.1

+VREF

+VREF

EXPLANATION OF TEST LEVELS

Test Level I

Test Level II

– 100% production tested.

– 100% production tested at 25°C and sample

tested at specified temperatures.

Test Level III – Sample tested only.

Test Level IV – Parameter is guaranteed by design and

characterization testing.

Test Level V – Parameter is a typical value only.

Test Level VI – All devices are 100% production tested at

25°C. 100% production tested at temperature

extremes for extended temperature devices;

sample tested at temperature extremes for

commercial/industrial devices.

ORDERING GUIDE

Model

Package

Linearity Temperature Range Option*

AD9002AD

AD9002BD

AD9002AJ

AD9002BJ

AD9002SD/883B

AD9002TD/883B

0.75 LSB

0.50 LSB

0.75 LSB

0.50 LSB

0.75 LSB

0.50 LSB

–25°C to +85°C

–25°C to +85°C

–25°C to +85°C

–25°C to +85°C

–55°C to +125°C

–55°C to +125°C

*D = Ceramic DIP; J = Ceramic Chip Carrier, J-Formed Leads.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD9002 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

REV. G

–3–

D-28

D-28

J-28

J-28

D-28

D-28

AD9002

FUNCTIONAL DESCRIPTION

Pin No.

Mnemonic

Description

1

2

DIGITAL GROUND

OVERFLOW INH

One of Four Digital Ground Pins. All digital ground pins should be connected together.

OVERFLOW INHIBIT controls the data output polarity for overvoltage inputs.

3

HYSTERESIS

4

5

6

7

+VREF

ANALOG INPUT

ANALOG GROUND

ENCODE

8

9

10

11

12

13

14

ENCODE

ANALOG GROUND

ANALOG INPUT

–VREF

REFMID

DIGITAL GROUND

DIGITAL –VS

15

16–19

20

21, 22

D1 (LSB)

D2–D5

DIGITAL GROUND

ANALOG –VS

23

24, 25

26

27

DIGITAL GROUND

D6, D7

D8 (MSB)

OVERFLOW

28

DIGITAL –VS

Analog Input

Overflow Enabled

(Floating or –5.2 V)

of D1–D8

Overflow Inhibited (GND)

of D1–D8

VIN > +VREF

1 0 0 0 0 0 0 0 0

0 1 1 1 1 1 1

VIN ≤ +VREF

0 X X X X X X X X

0 X X X X X X X X

1 1

The hysteresis control voltage varies the comparator hysteresis from 0 mV to 10 mV, for a change

from –5.2 V to –2.2 V at the hysteresis control pin. Normally converted to –5.2 V.

The Most Positive Reference Voltage for the Internal Resistor Ladder

One of Two Analog Input Pins. Both analog input pins should be connected together.

One of Two Analog Ground Pins. Both analog ground pins should be connected together.

Noninverted Input of the Differential ENCODE Input. This pin is driven in conjunction with

ENCODE. Data is latched on the rising edge of the ENCODE signal.

Inverted Input of the Differential ENCODE Input. This pin is driven in conjunction with ENCODE.

One of Two Analog Ground Pins. Both analog ground pins should be connected together.

One of Two Analog Input Pins. Both analog inputs should be connected together.

The Most Negative Reference Voltage for the Internal Resistor Ladder

The Midpoint Tap on the Internal Resistor Ladder

One of Four Digital Ground Pins. All digital ground pins should be connected together.

One of Two Negative Digital Supply Pins (Nominally –5.2 V). Both digital supply pins should be

connected together.

Digital Data Output

Digital Data Output

One of Four Digital Ground Pins. All digital ground pins should be connected together.

One of Two Negative Analog Supply Pins (Nominally –5.2 V). Both analog supply pins should be

connected together.

One of Four Digital Ground Pins. All digital ground pins should be connected together.

Digital Data Output

Digital Data Output

Overflow Data Output. Logic high indicates an input overvoltage (V IN > +VREF) if OVERFLOW

INH is enabled (overflow enabled, –5.2 V). See OVERFLOW INH.

One of Two Negative Digital Supply Pins (Nominally –5.2 V). Both digital supply pins should

be connected together.

PIN DESIGNATIONS

D7

ANALOG INPUT 5

ANALOG 6

GROUND

24

D6

ENCODE 7

25 24 23 22 21 20 19

DIGITAL

GROUND

22 ANALOG –VS

23

AD9002

TOP VIEW

ENCODE 8 (Not to Scale) 21 ANALOG –VS

ANALOG 9

20 DIGITAL

GROUND

GROUND

19 D5

ANALOG INPUT 10

–VREF 11

18

D4

REFMID 12

17

D3

16

D2

15

D1(LSB)

DIGITAL 13

GROUND

DIGITAL –VS 14

D5

25

ANALOG –VS

DIGITAL GROUND

D8(MSB)

+VREF 4

DIGITAL GROUND

26

–4–

D8(MSB)

26

18

D4

OVERFLOW

DIGITAL –VS

DIGITAL

GROUND

OVERFLOW INH

HYSTERESIS

27

17

3

13

+VREF

4

12

D3

D2

D1(LSB)

DIGITAL –VS

DIGITAL

GROUND

REFMID

28

1

AD9002

16

TOP VIEW

15

(Not to Scale)

2

9

10

14

5

6

7

8

ENCODE

ANALOG GROUND

ANALOG INPUT

–VREF

OVERFLOW

HYSTERESIS 3

ENCODE

DIGITAL –VS

27

ANALOG INPUT

28

OVERFLOW INH 2

ANALOG GROUND

DIGITAL 1

GROUND

ANALOG –VS

JLCC

D7

D6

DIP

11

REV. G

AD9002

N+1

ANALOG

INPUT

N

N+2

APERTURE

DELAY

ENCODE

t PD

OUTPUT

DATA

N–1

N+1

N

Figure 1. Timing Diagram

AD9002

+VREF

AD9002

R

AD9002

R/2

REFMID

ENCODE

ANALOG

INPUT

ENCODE

R/2

–5.2V

–5.2V

DIGITAL

OUTPUT

R

–VREF

–5.2V

–5.2V

–5.2V

COMPARATOR CELLS

Figure 2. Input/Output Circuits

OVERFLOW

INH

HYSTERESIS

DIGITAL

GROUND

DIGITAL –VS

OVERFLOW

0.1F

–5.2V

–VS

HYSTERESIS

OVERFLOW INH

100

AD1

AD2

1k

OVERFLOW

ANALOG IN

1k

1k

1k

ANALOG

GROUND

1k

ENCODE

1k

ANALOG –VS

DIGITAL

GROUND

1k

AD9002

+VREF

GROUND

STATIC BURN IN

AD1 = 0V

AD2 = ECL HIGH

DYNAMIC BURN IN

D3

ANALOG

GROUND

1k

D2

1k

D1

D5

ANALOG

INPUT

D4

AD3 = ECL LOW

AD1

0V

D1 (LSB)

DIGITAL

GROUND DIGITAL

REFMID

–VS

–VREF

–2V

ECL HIGH

AD2

D2

D3

ECL LOW

Figure 4. Die Layout and Mechanical Information

ECL HIGH

AD3

ECL LOW

ALL RESISTORS 5%

ALL CAPACITORS 20%

ALL SUPPLIES 5%

Figure 3. Burn-In Diagram

REV. G

DIGITAL

GROUND

ENCODE

D4

–VREF

0.1F

D6

1k

D5

ENCODE

–2V

D7

D7

ANALOG

INPUT

1k

D6

ENCODE

AD3

D8

D8 (MSB)

+VREF

Die Dimensions . . . . . 106 mils × 114 mils × 15 mils (± 2 mils)

Pad Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 4 mils × 4 mils

Metalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Gold

Backing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . None

Substrate Potential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –VS

Passivation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Nitride

Die Attach . . . . . . . . . . . . . . . . . . . . . Gold Eutectic (Ceramic)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Epoxy (Plastic)

Bond Wire . . . . . . . . . . 1 mil–1.3 mil Gold; Gold Ball Bonding

–5–

AD9002

APPLICATION INFORMATION

LAYOUT SUGGESTIONS

The AD9002 is compatible with all standard ECL logic families,

including 10K and 10KH. 100K ECL logic levels are temperature

compensated and are therefore compatible with the AD9002 (and

most other ECL device families) only over a limited temperature

range. To operate at the highest ENCODE rates, the supporting logic

around the AD9002 will need to be equally fast. Whichever

ECL logic family is used, special care must be exercised to keep

digital switching noise away from the analog circuits round

the AD9002. The two most critical items are digital supply

lines and digital ground return.

Designs using the AD9002, such as all high speed devices,

must follow a few basic layout rules to ensure optimum performance. Essentially, these guidelines are meant to avoid many

of the problems associated with high speed designs. The first

requirement is for a substantial ground plane around and

under the AD9002. Separate ground plane areas for the digital and

analog components may be useful, but these separate grounds

should be connected together at the AD9002 to avoid the

effects of ground loop currents.

The input capacitance of the AD9002 is an exceptionally low

17 pF. This allows the use of a wide range of input amplifiers,

both hybrid and monolithic. To take full advantage of the wide

input bandwidth of the AD9002, a hybrid amplifier such as the

AD9610 will be required. For those applications that do not

require the full input bandwidth of the AD9002, more traditional monolithic amplifiers, such as the AD846, will work very

well. Overall performance with any amplifier can be improved

by inserting a 10 Ω resistor in series with the amplifier output.

The output data is buffered through the ECL compatible output

latches. All data is delayed by one clock cycle, in addition to the

latch propagation delay (tPD), before becoming available at the

outputs. Both the analog-to-digital conversion cycle and the

data transfer to the output latches are triggered on the rising

edge of the differential, ECL compatible ENCODE signal (see

Figure 1). In applications where only a single-ended signal is available, the AD96685, a high speed, ECL voltage comparator, can

be employed to generate the differential signals. All ECL signals (including the overflow bit) should be terminated properly to

avoid ringing and reflection.

The AD9002 also incorporates a HYSTERESIS control pin

that provides from 0 mV to 10 mV of additional hysteresis in the

comparator input stages. Adjustments in the HYSTERESIS

control voltage may help improve noise immunity and overall

performance in harsh environments.

The OVERFLOW INH pin of the AD9002 determines how

the converter handles overrange inputs (AIN ≥ +VREF). In the

“enabled” state (floating at –5.2 V), the OVERFLOW INH output will be at logic HIGH and all other outputs will be at logic

LOW for overrange inputs (return-to-zero operation). In the

“inhibited” state (tied to ground), the OVERFLOW INH

output will be at logic LOW, and all other outputs will be at

logic HIGH for overrange inputs (nonreturn-to-zero operation).

The second area that requires an extra degree of attention involves

the three reference inputs, +VREF, REFMID, and –VREF. The

+VREF input and the –VREF input should both be driven from a

low impedance source (note that the +VREF input is typically

tied to analog ground). A low drift amplifier should provide

satisfactory results, even over an extended temperature range.

Adjustments at the REFMID input may be useful in improving the

integral linearity by correcting any reference ladder skews. The

application circuit shown below demonstrates a simple and

effective means of driving the reference circuit.

The reference inputs should be adequately decoupled to ground

through 0.1 µF chip capacitors to limit the effects of system noise

on conversion accuracy. The power supply pins must also be

decoupled to ground to improve noise immunity; 0.1 µF and

0.01 µF chip capacitors are recommended.

The analog input signal is brought into the AD9002 through

two separate input pins. It is very important that the two input

pins be driven symmetrically with equal length electrical connections. Otherwise, aperture delay errors may degrade converter

performance at high frequencies.

–15V

1k

4k

100

0.1F

ANALOG

INPUT

(0V TO 2V)

2N3906

10

AD741

0.1F

NYQUIST

FILTER

–VREF +VREF

1.5k

1.5k

40

50

AIN

AD9611

The AD9002 provides outstanding error rate performance. This

is due to tight control of comparator offset matching and a fault

tolerant decoding stage. Additional improvements in error rate

are possible through the addition of hysteresis (see HYSTERESIS

control pin). This level of performance is extremely important in

fault sensitive applications, such as digital radio (QAM).

ENCODE

INPUT

(GROUND

THRESHOLD)

AIN

AD9002

ENCODE

50

ENCODE

AD96685

0.01F

Dramatic improvements in comparator design and construction

give the AD9002 excellent dynamic characteristics, especially

SNR (signal-to-noise ratio). The 160 MHz input bandwidth

and low error rate performance give the AD9002 an SNR of

48 dB with a 1.23 MHz input. High SNR performance is particularly important in wide bandwidth applications, such as

pulse signature analysis, commonly performed in advanced

radar receivers.

OVERFLOW

D8 (MSB)

D7

D6

D5

D4

D3

D2

D1 (LSB)

EQUAL

DISTANCE

–5.2A –5.2D

0.1F

0.1F

0.01F

Figure 5. Typical Application

–6–

REV. G

AD9002

LINEARITY OUTPUT

(ERROR WAVEFORM)

HOS100

RECONSTRUCTED

OUTPUT

HOS100

50

1k

4.3k

1k

–15V

3.75

150

AD741

0.1F

2N3906

90 20 90

0.01F

AD9768

DAC

0.1F

50

HOS200

75

ANALOG

INPUT

–VREF

AIN

10F

REFMID

+VREF

OVERFLOW

EQUAL

DISTANCE

50

2k

D8(MSB)

D7

AIN

D6

AD96687

ENCODE

1k

0.1F

D2

D1(LSB)

0.1F

1k

37-PIN

D

CONNECTOR

D3

HYSTERESIS

–15V

LINE

DRIVER

100114

D4

OVERFLOW

INH

3.9k

REGISTER

100151

D5

AD9002*

ENCODE

–5.2A

–5.2D

625

–5.2V

ENCODE INPUT

(GROUND

THRESHOLD)

0.1F

0.1F

0.01F

AD96687

0.01F

AD96687

AD96687

510

50

*CONTACT FACTORY ABOUT

EVALUATION BOARD AVAILABILITY

510

0.1F

–5.2V

–5.2V

DELAY

13k

1k

880

DELAY

13k

–15V

1k

880

–15V

Figure 6. AD9002 Evaluation Circuit

RMS SIGNAL-TO-NOISE RATIO (dB)

AND HARMONIC LEVELS (–dBc)

65

60

55

SECOND HARMONIC

THIRD HARMONIC

50

SNR

45

40

35

30

10MHz

100MHz

1MHz

ANALOG INPUT FREQUENCY (0.1dB BELOW FULL SCALE)

125 MSPS ENCODE RATE

Figure 7. Dynamic Performance

REV. G

–7–

100114 LINE DRIVER OUTPUTS

REQUIRE 510 PULL-DOWN

RESISTORS TO –5.2V. ALL OTHER

ECL OUTPUTS SHOULD BE

TERMINATED TO –2V WITH

100 RESISTORS, UNLESS

OTHERWISE SPECIFIED.

AD9002

OUTLINE DIMENSIONS

28-Lead Ceramic Chip Carrier - J-Formed Leads [ JLCC]

(J-28A)

Dimensions shown in inches and (millimeters)

0.040 (1.02)

REF

x 45

3 PLACES

0.460 (11.68)

SQ

0.440 (11.18)

4

26

5

0.035 (0.89)

0.025 (0.64)

25

0.020 (0.51)

REF

x 45

26

4

25

5

PIN 1 INDEX

0.055 (1.40)

PIN 1

0.450 (11.43)

0.410 (10.41)

0.050

(1.27)

C00545–0–5/03(G)

0.125 (3.18)

MAX

0.310 (7.87)

0.290 (7.37)

TOP VIEW

BOTTOM VIEW

0.022 (0.56)

0.012 (0.30)

11

19

12

19

18

11

18

12

0.500 (12.70)

SQ

0.480 (12.19)

CONTROLLING DIMENSIONS ARE IN INCHES; MILLIMETERS DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF INCH EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

28-Lead Side-Brazed Ceramic Dual In-Line Package [SBDIP]

(D-28)

Dimensions shown in inches and (millimeters)

0.005 (0.13)

MIN

0.100 (2.54)

MAX

28

15

0.610 (15.49)

0.580 (12.73)

PIN 1

1

1.490 (37.85) MAX

0.085 (2.16)

MAX

0.200 (5.08)

0.125 (3.18)

14

0.026 (0.66)

0.014 (0.36)

0.100 (2.54)

0.060 (1.52)

0.015 (0.38)

0.070 (1.78)

0.030 (0.76)

0.620 (15.75)

0.590 (14.99)

0.150

(3.81)

MIN

SEATING

PLANE

0.018 (0.46)

0.008 (0.20)

CONTROLLING DIMENSIONS ARE IN INCHES; MILLIMETER DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF INCH EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

Revision History

Location

Page

5/03—Data Sheet changed from REV. F to REV. G.

Deleted the E-28A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Universal

Changes to OUTLINE DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Data Sheet changed from REV. E to REV. F.

Edit to ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

–8–

REV. G