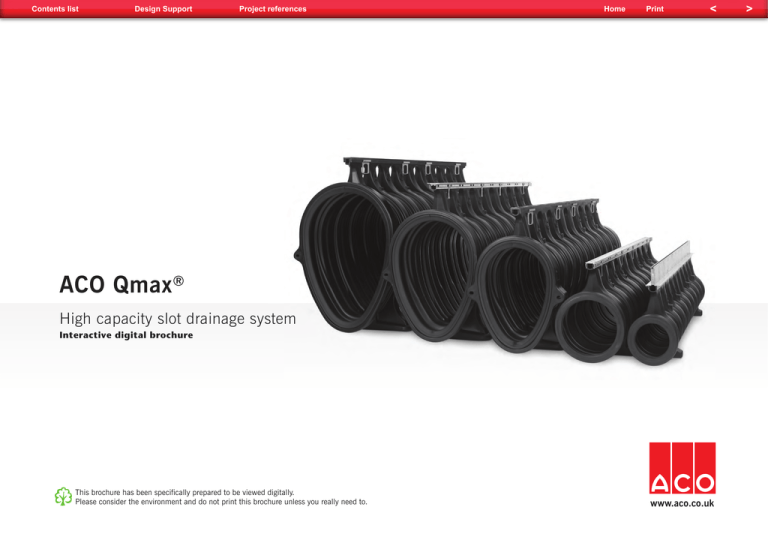

ACO Qmax®

advertisement