Application Example: 3D Motion Analysis

Development: 3D Windscreen Wiper Deformation

Measuring Systems: PONTOS

Keywords: Windscreen wiper

The deformation behavior of a windscreen wiper must be determined at the

point of turn over. Both the local displacement normal to the windscreen and

the inplane deformation of the wiper are interesting in order to analyze the

impulse of the wiper onto the windscreen and generate enough data to

improve the wipers‘ performance.

GOM mbH

Mittelweg 7-8

38106 Braunschweig

Germany

Phone

+49 531 390 29 0

Fax

+49 531 390 29 15

info@gom.com

Copyright ©

GOM International AG

Bremgarterstrasse 89B

8967 Widen

Switzerland

Phone

+41 5 66 31 04 04

Fax

+41 5 66 31 04 07

international@gom.com

2009 GOM mbH

GOM France SAS

10 Quai de la Borde - Bât A2

91130 Ris Orangis

France

Phone

+33 1 60 47 90 50

Fax

+33 1 69 06 63 60

info-france@gom.com

All rights reserved!

GOM UK Ltd

Business Innovation Centre

Coventry, CV3 2TX

Great Britain

Phone

+44 2476 430 230

Fax

+44 2476 430 001

info-uk@gom.com

Rev. A (en) 20022009

www.gom.com

GOM Branch Benelux

Interleuvenlaan 15 E

3001 Leuven

Belgium

Phone

+32 16 408 034

Fax

+32 16 408 734

info-benelux@gom.com

1

3D Motion Analysis / Development

3D Windscreen Wiper Deformation

Modern cars are designed with large windscreens to cope with the requirements of the aerodynamics. This also affects the design and performance of

windscreen wipers, specifically at higher speeds. Uncontrolled behavior of

wipers, due to elastic deformation and unsteady friction cause rattle and

unsatisfactory wiping performance. Uncontrolled behavior of wipers at the

point of turn over causes an impulse on the windscreen and therefore undesirable noise inside the car. So far, accelerometers and interferometers are used to

determine the wiper deformation. However the tests are time consuming and

the results are not very conclusive. While an accelerometer setup affects the

dynamic behavior, the interferometer setup measures only one point at a time

and requires an adaptation for each specific test. Fast and easy to apply optical

3D measurement techniques are used to solve this issue.

Task:

The deformation behavior of a windscreen wiper must be determined at the

point of turn over. Both the local displacement normal to the windscreen and

the inplane deformation of the wiper are interesting in order to analyze the

impulse of the wiper onto the windscreen and generate enough data to

improve the wipers performance. This measurement must take place during a

fast wiper motion despite the large global movement. Furthermore, more than

one point on the wiper is of interest, several points along the wipers blade and

the wipers arm must be analyzed at the same time, without influencing the

overall behavior of the wiper.

Setup:

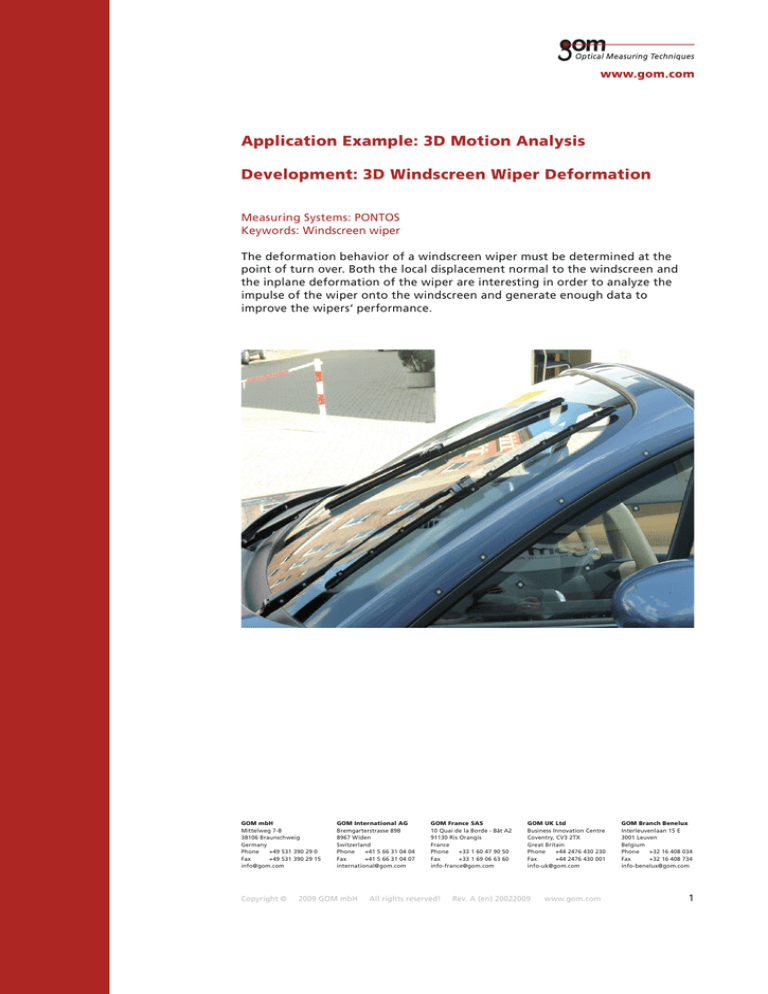

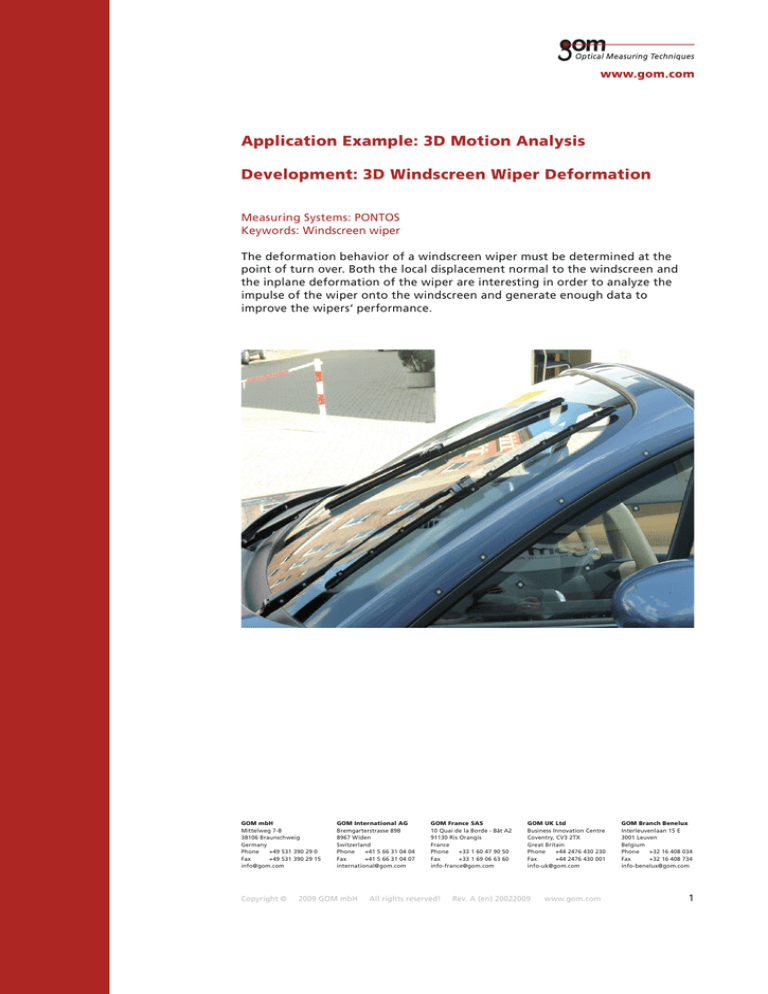

The optical 3D measurement system PONTOS is used to measure the 3D behavior of the wiper during the time of turn over. Ten optical markers are positioned

on the wiper at points of interest (Fig. 1). These adhesive markers are lightweight (< 0.05g) and do not influence or disturb the mechanism of the process.

The PONTOS sensor is positioned beside the car to observe the optical markers

(Fig. 2).

Fig 1: Marker positions

Fig 2: PONTOS position

The calibrated optical stereo camera setup then is able to determine the

position of each marker, for all markers at the same time. The high-speed data

acquisition with 300 Hz allows capturing the fast movement of the wiper and

generates enough data points for further detailed analysis.

Copyright ©

2009 GOM mbH

All rights reserved!

Rev. A (en) 20022009

www.gom.com

2

Results:

The 3D displacement of the wiper is displayed below. First the overall displacement of the wiper is shown on the video. The vectors on the movie (Fig. 3)

describe the quantitative 3D displacement of the markers attached to the wiper.

Fig 3: Quantitative 3D

displacement

The displacement normal to the windscreen at the point of turn over and the

displacement of the wiper in inplane direction is described in figure 4. Figure 5

shows the velocity of the wiper which indicates clear an unsteady motion of the

complete wiper system.

Fig 4: Graph showing displacement in Y

and Z direction

Fig 5: Velocity of the specified points at any

given time

Conclusion:

The results have shown the detailed analysis of a wiper at the point of turn

over. The advantages of optical 3D measurement are seen. Many points can be

measured at the same time. The sensor does not need to be connected to the

measuring object and no additional coordinate measurement is required. The

small and lightweight adhesive optical markers are easy and fast to apply and

do not influence the mechanical behavior of the parts to be tested. The setup of

the system inclusive the measurement was done in less than one hour, which is a

considerable time advantage in comparison to common measurement

techniques.

Copyright ©

2009 GOM mbH

All rights reserved!

Rev. A (en) 20022009

www.gom.com

3