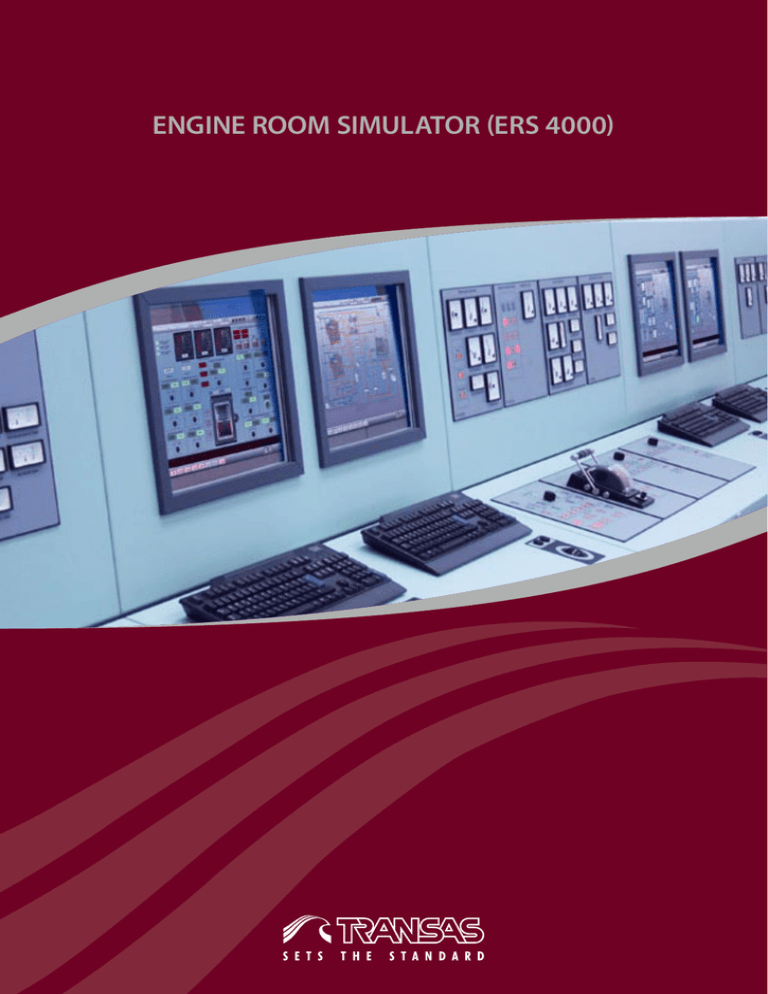

ENGINE ROOM SIMULATOR (ERS 4000)

Engine Room Simulator ERS 4000

ERS 4000 Network

PC-based Simulator Class

• Designed for group and team training

• Instructor control and monitoring

• Up to 12 interactive Trainee workstations

The Engine Room Simulator 4000, developed by Transas,

is a maritime simulator meant for the education, training

and assessment of engine department personnel, including officers in charge of watch, second and chief engineers.

ERS 4000 meets the requirements of the STCW‘95 Convention and Code. The simulator’s scope of training objectives corresponds to the specifications of standard competence for engine department personnel as to Chapter III

of STCW‘95, IMO Model Courses 2.07; 2.08; 7.02; 7.04; and

facilitates marine engineering training at the operational,

management and support levels. It is certified by Det Norske Veritas as Class A Simulator.

ERS class

Network workplace configuration is flexible and could be adjusted according to the training requirements

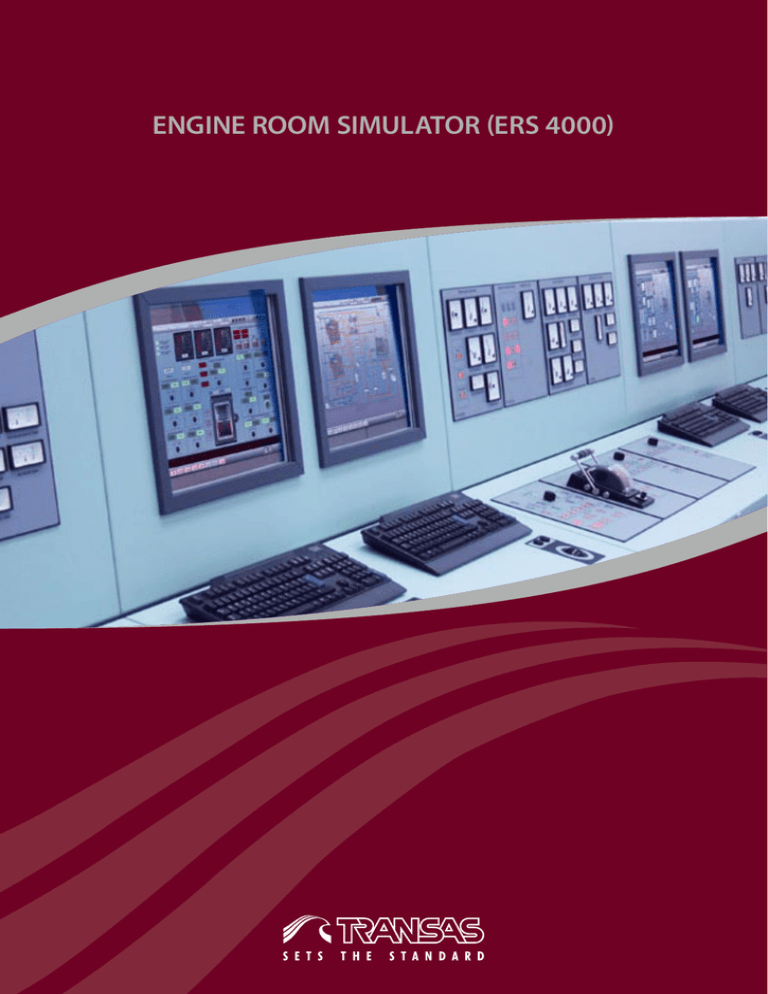

ERS 4000 Full-mission

‘Real’ Engine Room Consoles supplied with the Trainee Workstation:

Types of Training

• Designed for professional hands-on simulator training, including advanced operation and troubleshooting tasks

The high level of physical and behavioral realism of the

ERS 4000 creates a professional environment for the following types of marine engineering training:

Propulsion plant

• Familiarisation and education

• Standard operation and watch keeping

• Advanced operation and troubleshooting.

Areas of Application

Configuration

ERS 4000 Solo

• Panels are available for Ship’s Diesel Propulsion Plant with

Auxiliary systems and machinery and for Ship’s Electric Power Plant. Full interaction between simulator software and

hardware

• Any combination of ERS 4000 Network and Full-mission

workstations.

Single-PC Desktop System

Education

• Designed for self-education, equipment familiarisation

and knowledge refresher training

• Basic physical and technical knowledge

• Run on standalone PC

• Engine room equipment familiarisation

• Off-line Instructor functions include Exercise Editor

and Debriefing

• System layout and flow diagrams

• ‘Real’ simulated consoles with built-in monitoring and control panels

ERS full mission

• Control, Automation, Alarm and Safety systems

• Operational instructions

• Watch keeping procedures

Training

• Updating of seagoing engineering personnel

• Educating specialists from other related qualifications

• Refresher courses

Assessment of Competence

• Issue of qualification certificates

• Diploma revalidation and qualification

• Demonstration of professional competence

The wide application capabilities of the Transas ERS 4000

simulator make it the ideal solution for maritime colleges

and academies, training centres, shipping companies,

maritime authorities and crewing agencies.

Single-PC desktop system

2

3

Engine Room Simulator ERS 4000

Electric Power Plant

The Ship’s Electric Power Plant incorporated in ERS 4000 includes the main switch board and control panels for dieselgenerators, shaft-generator, turbo-generator, emergency

diesel-generator, shore supply, consumers, synchronising,

automatic and manual control modes, alarm and safety system.

Trainee Workstation

Propulsion Plant

The set of equipment simulated in ERS 4000 complies with the modern standard accepted for ships’ diesel and steam

turbine plants. To fully meet the engineering training requirements of its customers, Transas has simulated three of the

most widespread types of ship’s propulsion plant, including:

The simulator imitates the actual dynamics of the transition

processes, allowing the trainee to acquire the appropriate

operation skills.

Simulated Systems Include

• Diesel Generators

• Two-stroke slow-speed diesels: MAN B&W 6S60MC, MAN B&W 10K98MC, Wartsila-Sulzer 6RTA58 with a fixed pitch

propeller

• Shaft Generator

• Four-stroke medium-speed diesel of the SEMT Pielstick 16 PC2.2V-400 type with a controllable pitch propeller

• Shore Supply

• Four-stroke high-speed diesel of the Caterpillar 3508 TA type with reversible reduction gear and fixed pitch propeller

• Steam turbine cross-compound, double reduction geared (Kawasaki UA-400 as prototype)

Emergency switch board

• Turbo Generators

• Emergency Generator

• Sections of Main Switch Board and Emergency Switch

Board

• Consumers, feeders, earth monitoring, etc.

Simulated Systems Include

• Systems providing operation of propulsion complex

• United mimic diagram of systems with machinery and

units parameterisation functionality

Turbo Generator

­­­­

ERS

4000 incorporates an up-to-date simulated ship alarm

system with visual and acoustic signals and automatic logger, as well as a powerful safety system with slowdown and

shutdown functions and Dead Man system and Dead Man

system.

These systems are essential for the training of emergency

situations and equipment failures on all types of engine

room equipment.

General Cargo 2 main engine control

Main switch board

Auxiliary Systems

The extensive range of Auxiliary systems and Machinery

subsystems modeled in ERS 4000 meets the ever growing

requirements set forth for marine engineering simulator

training.

Incinerator

The set of Auxiliary Systems and mechanisms is compliant

with MARPOL and SOLAS requirements.

Simulated Systems Include

• Steering Gear

• Ballast System

• Sewage Treatment System

• Incinerator

Fuel oil supply system

SCSW of Tanker LNG

• Steam Plant

• Fire systems

• Bilge Systems

• Refrigeration Systems, etc.

Ballast system

4

5

Engine Room Simulator ERS 4000

‘Virtual Reality’ Engine Room

The 3D Engine Room is an innovative module included in

the Transas ERS 4000 simulator.

With this module, simulator users can solve the following

training tasks:

• ‘3-D virtual reality’ of the Engine Room area for familiarisation support

• Standard and Advanced operation, including troubleshooting

• System mimic diagrams and local control places

• Familiarisation with Engine Room sounds

Ship’s diesel propulsion plant

Hardware Controls

To simulate the vessel interior with greater realism and thus further improve the

efficiency of training, ERS 4000 can be supplied with full-size control consoles

comprising built-in monitoring and control panels, as well as computers.

The hardware consoles included in ERS 4000 imitate:

• Integrated Engine Control Room control desk

• Main Switchboard and Emergency Switchboard of the Ship’s Electric Power

Plant

• Engine Room local control places

• Monitoring and control panels ensuring the inspection of the majority of

simulator systems and their control

• Alarm panels

• Sounds and noises of all the major engine room devices, as well as alarm

sound signals

• Sound & Visual Alarm Unit. ERS 4000 transmits the complete set of alarm signals to this newly-implemented device

External equipment may be connected to create customized controls configuration through universal hardware interface.

All sets of ‘real’ consoles supplied with ERS 4000 are provided with built-in computers connected to a lo cal network, which ensures the full interactivity between all the components of the simulator.

Ship’s electric power plant

6

Main switchboard

7

Engine Room Simulator ERS 4000

Instructor Station

ERS 4000 is an excellent tool for carrying out professional

education, training, and knowledge assessment of ship’s

engineers, under the supervision of an Instructor. Advanced exercise monitoring and analysis functions of the

simulator’s Instructor Station make ERS 4000 applicable

for training tasks of practically any level of complexity.

Up to 12 interactive Trainee Stations can be controlled

from a single Instructor Station.

Training of bridge personnel

Exercise Editing

• Generation of new exercises

Integration with Navigational Simulator

• Editing of existing exercises

• Access to existing and creation of new training scenarios

Using the open architecture and modular design structure of its simulator systems, Transas has allowed for the integration of the ERS 4000 and NTPRO 4000

shiphandling simulator into a single interactive training environment.

• Transas is able to provide courseware packages according to SRCW’95 requirements

The combined training of engineering personnel and deck officers in a single

exercise solves the following tasks:

On-line Class

• Training of efficient and well-coordinated cooperation between the engine

room and bridge crews as it is onboard the real ship

• Exercise monitoring, on-line control of a class network

• Introduction of equipment faults, changing preset exercise parameters in the on-line mode

• Recording of all the events at Trainee workstations

• Various ship models could be appointed for different

trainees at the same time; the task could be appointed

for individual, team and crew training

Instructor place

Competence Assessment

• Training of emergency situations

• A set of standard tests on maritime qualifications

for competence assessment exercises

• Advanced equipment familiarisation necessary due to the increased level of

automation on board ships, where modern engine monitoring and control

devices are installed on the bridge (in accordance with the IMO ‘Watch 1’ standard)

• Results database for training statistics

Debriefing

The ERS 4000 Instructor Station incorporates the following

equipment:

• Post-exercise analysis of trainee performance

• Dual-head computer

• Replay of recorded exercises in real, fast and slow time

or in the step-by-step mode

• LAN server

Such integrated training is now increasingly demanded by:

• Maritime training centres and schools, where dual qualifications (watch officer/engineer) are available

• Shipping companies training their crews onboard and ashore

• Color printer

• Advanced shiphandling simulator courses designed for crews of vessels with

an A1/A2 automation class

• Projector.

Instructor station

• Understanding of the complexity of all onboard equipment and interactions

Instructor slave monitor

Training of engine room personnel

8

9

Engine Room Simulator ERS 4000

General Cargo-2

Model Description

Multipurpose general cargo-containership of 12.000 DWT, having

a two-stroke reversible low-speed turbo charged diesel, and direct

transmission to a fixed pitch propeller.

Main Engine

Type

Cylinder bore, mm

Piston stroke, mm

No. of cylinders

MCR, kW

Corresp. Engine speed, rpm

Propeller

MEP, bar

Propeller blades

ERS 4000 Available Ship Models

ERS 4000 incorporates the library of ship models with the most widespread types of propulsion plant. The model

library is constantly growing. Customised models can be developed on demand, given that a customer provides the

necessary technical data on the vessel’s engine room equipment.

The following Ship Models are available now:

Dry-Cargo Vessel/Container Ship

Model Description

Multipurpose dry-cargo vessel/container ship of 12,000 DWT, carrying general cargo, 20’ and 40’ containers.

Main engine: two-stroke low-speed reversible turbo charged diesel

engine with fixed pitch propeller.

Vessel

Length o.a., m

Breadth mld, m

Draught at design WL, m

Deadweight at SLM, t

Speed in full load, kn

Main Engine

Type

Cylinder bore, mm

Piston stroke, mm

No. of cylinders

MCR, kW

Corresp. Engine speed, rpm

Propeller

Propeller blades

137.40

21.50

7.50

12,000

19.1

Vessel

Length o.a., m

Breadth mld, m

Draught at design WL, m

Deadweight at SLM, t

Cargo holds capacity, m3

Speed in full load, kn

LNG Tanker

Model Description

LNG tanker of 76,000 DWT, with a steam turbine as the main engine, driving a fixed pitch propeller via a turning gearbox.

Man B&W 6S60MC

600

2292

6

12,240

105

FPP

4

Vessel

Length o.a., m

Breadth mld, m

Draught at design WL, m

Deadweight at SLM, t

Cargo tanks, m3

Speed in full load, kn

Main Engine

Type

Output MCR, kW

Output NCR, kW

Steam conditions at inlet

Condenser vacuum at top

(pump cooling)

Superheated steam

RO-RO Vessel

Model Description

Ro-Ro vessel of 5,000 DWT, with a four-stroke medium-speed

non-reversible turbo charged diesel engine and controllable

pitch propeller.

Propeller

Vessel

Length o.a., m

Breadth mld, m

Draught at design WL, m

Deadweight at SLM, t

Speed in full load, kn

Main Engine

Type

Container Ship

Model Description

Containership of 83,105 DWT with a two-stroke reversible lowspeed turbo charged diesel with fixed pitch propeller.

Cylinder bore, mm

Piston stroke, mm

No. of cylinders

MCR, kW

Corresp. Engine speed, rpm

Propeller

Propeller blades

S.E.M.T. Pielstick 16

PC2.2 V-400

400

460

16

5,966

520

CPP

4

Vessel

Length o.a., m

Breadth mld, m

Draught at design WL, m

Deadweight at SLM, t

Speed in full load, kn

277.40

40.0

13.3

83,105

24.9

Main Engine

Type

Cylinder bore, mm

Piston stroke, mm

No. of cylinders

MCR, kW

Corresp. Engine speed, rpm

Propeller

Propeller blades

10

124.09

19.20

6.30

5,000

16.6

MAN B&W 10K98MC

980

2660

10

57,200

94

FPP

4

Oil Tanker

Model Description

Oil tanker of 60,500 DWT, with a two-stroke low-speed reversible turbo charged diesel engine and fixed pitch propeller. The

Auxiliary systems: Oily Water Treatment System & Incinerator

added according to MARPOL requirements.

Fishing Vessel

Model Description

Trawler with a four-stroke high-speed turbo charged diesel engine, reversible reduction gear and fixed pitch propeller.

Vessel

Length o.a., m

Breadth mld, m

Draught at design WL, m

Deadweight at SLM, t

Speed in full load, kn

Main Engine

Type

Cylinder bore, mm

Piston stroke, mm

No. of cylinders

MCR, kW

Corresp. Engine speed, rpm

Propeller

Propeller blades

Vessel

Length o.a., m

Breadth mld, m

Draught at design WL, m

Deadweight at SLM, t

Speed in full load, kn

Main Engine

Type

Cylinder bore, mm

Piston stroke, mm

No. of cylinders

MCR, kW

Corresp. Engine speed, rpm

Propeller

Propeller blades

137.40

21.50

7.50

12,000

14.950

19,1

Wartsila-Sulzer RTA58

580

2416

6

12,750

105

FPP

19

4

276.0

43.40

11.01

76,134

137,585

19,5

Kawasaki UA-400

29,450

25,040 / 85,3 R.P.M.

57,4 bar, 515 oC

722 mmHg Vac. at M.C.R.

61,5 bar / 515 oC / 63,500kg/h

at M.C.R. condition

FPP

242.8

32.2

12.50

67,980

13,6

MAN B&W 6S60MC

600

2,292

6

12,240

105

FPP

4

24.5

6.31

3.25

250

11

CATERPILLAR 3508 TA

170

190

8

526

1,200

FPP

4

11

TRANSAS WORLD-WIDE DISTRIBUTORS AND SERVICE NETWORK

TRANSAS INTERNATIONAL

HEADQUARTERS

tel.:

fax:

e-mail:

internet:

+353 (0) 21 4 710 400

+353 (0) 21 4 710 410

information@transas.com

www.transas.com

© Copyright 2008, Transas Ltd. All rights reserved.