PACKER FLUIDS

N-SOLATE® Insulating Packer Fluids

N-SOLATE® High Performance Insulating Packer Fluids

Business Challenge

One of the challenges for production design is the potential for

uncontrolled heat transfer to outer annuli and heat loss from the

production tubing. This can damage outer annuli integrity, reduce

productivity, and even lead to casing collapse. Under uncontrolled

conditions, paraffin and asphaltene deposits and hydrate formations

can occur.

N-SOLATE® high-performance insulating packer fluids were

created according to these criteria, and can effectively control

unwanted heat loss by reducing both conduction and convection

for the life of the well, providing the best overall performing

thermally insulating packer fluid on the market today.

Convective

Conductive

Heat Source

Heat Source

HAL22091

With both modes intact,

heat transfers quickly

through liquids

Benefits

N-SOLATE high-performance insulating packer fluids can help

reduce both conduction and convection heat loss for the life of

the well, helping to prevent annular pressure buildup and

maintain wellbore integrity, and ultimately providing an increase

in production potential for the well. In addition, N-SOLATE

packer fluids are a lower-cost alternative to traditional methods

such as vacuum-insulated tubing (VIT), and help reduce the

costly risks associated with uncontrolled heat loss.

• Higher production potential

Overview

Studies of effective methods to minimize heat transfer have

identified four essential fluid characteristics for successful insulation:

• Lower cost as opposed to traditional methods

• Tolerance for high temperatures

• Maintains wellbore integrity

• Low thermal conductivity

• Compatible with most wellbore fluids

• No suspended solids as weighting agents

• Easily removed from the wellbore

• Long-term stability in the well

• Environmentally friendly, with low GOM toxicity and

low oil and grease

• Prevents annular pressure buildup for the life of the well

• Control and prevent heat loss for the life of the well

Features

The N-SOLATE system is a new-generation insulating-packer

fluid. Past systems utilizing biopolymers are simply not durable

enough to provide long-term assurance. Baroid set out to develop

a system which would remain durable for greater than 6 months

at 300°F (149°C). This effort has yielded tremendous success and

Halliburton now offers four systems:

HAL22090

• N-SOLATE 175 system: effective up to 175°F (79°C)

Compatibility results with crude oil, propylene glycol, methanol, and

control line fluid, left to right. Contaminants were added at 20% by

volume and allowed to equilibrate 24 hours at 70°F (21°C).

• N-SOLATE 275 system: effective up to 275°F (135°C)

• N-SOLATE 400 system: effective up to 400°F (204°C)

• N-SOLATE 600 system: effective up to 600°F (316°C)

PACKER FLUIDS

N-SOLATE Applications

Baroid’s N-SOLATE insulating packer

fluids are suitable for several applications,

including deepwater, HP/HT, steam injection,

and permafrost.

These systems have taken insulating-packer fluid technology to a new level and offer:

• Thermal Conductivity (k) of 0.123 to 0.177 BTU/(hr*ft*°F)

• Thermal stability from 90°F to 600°F (32°C to 316°C)

• Density range from 8.5 lb/gal to 15.0 lb/gal

• Pumpable viscosity with heat-activated cross-link

The N-SOLATE fluids are hydrate-inhibitive,

pass oil and grease testing, and can be

formulated to meet or exceed strict

environmental criteria, including that of the

Gulf of Mexico. Extensive testing has shown

that the N-SOLATE fluids are chemically

compatible with propylene glycol, methanol,

crude oil, control line fluids, and numerous

mono- and divalent brines. In addition,

N-SOLATE fluid exhibits excellent flow

assurance capabilities; helps prevent annular

pressure buildup; helps maintain lower ECD

(equivalent circulating density), and can be

used in environmentally sensitive areas.

• Covalently cross-linked (as opposed to ionically cross-linked)

• Hydrate-inhibitive to >8,500 psi at 40°F (>58.6 MPa at 4°C) (can be engineered

to higher pressure with density limitations)

• Environmentally friendly: Oil and grease content <8 mg/L and LC-50 >100,000

The N-SOLATE 600 system is truly a unique fluid. The ability to withstand

temperatures in excess of those that metallurgical components can is quite a feat by

itself. But, N-SOLATE 600 fluid is also not subject to thermal thinning, guaranteeing

enough viscosity is retained to eliminate or minimize convective heat loss. The

N-SOLATE system uses nanotechnologies to achieve its performance objectives

and becomes one of the first uses of nanotechnology in oilfield-fluids applications.

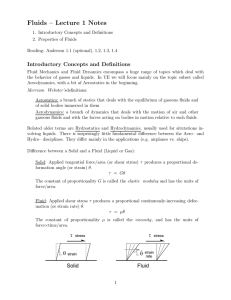

Baroid Thermal Insulation Fluid Project

Temperature Profile of Wellbore Model with Water and Test Fluid

N-SOLATE fluid viscosity and gel strength

can be customized for each individual

application to help ensure that fluid density

is supported over the long term.

180

170

Lower T.C. Line, Fluid

Medium T.C. Line, Fluid

Upper T.C. Line, Fluid

Lower T.C. Line, Water

Medium T.C. Line, Water

Upper T.C. Line, Water

160

150

130

120

110

100

90

80

70

60

50

40

0

0 .3 5 2

0 .7 0 4

HAL24604

30

1 .0 5 6

Distance from Cold Water, Inches

N-SOLATE 600 System

100

Viscosity (cP)

10000

200

400

300

500

600

1000

100

10

0

5000

10000

15000

20000

25000

Time (s)

30000

35000

Conculsion

N-SOLATE packer fluids can provide

reliable, cost-effective protection when

it comes to uncontrolled heat loss. The

N-SOLATE water-based packer fluids have

been shown to outperform other options by

1 .4 0 8

meeting all the technical criteria as well as

minimizing environmental impact. With

outstanding thermal

stability capabilities and

density ranges, N-SOLATE

fluids have been proven to

3 rpm (5.0 s -1)

help improve production

rates while significantly

N-Solate-600

N-SOLATE

600 System

lowering costs in

60 rpm (102 s -1)

deepwater and steam

45000

injection operations.

40000

HAL24603

Temperature, °F

140

© 2012 Halliburton. All rights reserved. Sales of Halliburton products and services will be in accord solely with the terms and conditions contained in the

contract between Halliburton and the customer that is applicable to the sale.

H05923 4/12

www.halliburton.com