2

SCHEME DESCRIPTION

2.1

OUTLINE OF THE PROPOSED SCHEME

2.1.1

Overview

APCL are currently progressing a proposal to develop a power generation

plant at a site on the former BP Chemicals Baglan Bay Works at Seaway

Parade, Port Talbot, in South Wales.

The proposed development will involve the construction of a base load, gas

fired Combined Cycle Gas Turbine (CCGT) power plant, with no dual fuel

option, which will be connected to the existing zone 13 National Grid System.

It will be rated to provide up to 870 MW of generation capacity.

The proposed plant will be constructed within the former BP Chemicals

Baglan Bay Works Site adjacent to the existing Baglan Power Station, which is

operated by GE.

The facility will comprise two gas turbine generators with associated Heat

Recovery Steam Generators (HRSGs). Exhaust gases from the HRSGs will be

discharged from a single multi flue stack.

Low level plume abated cooling towers will be utilised to minimise the visual

impact.

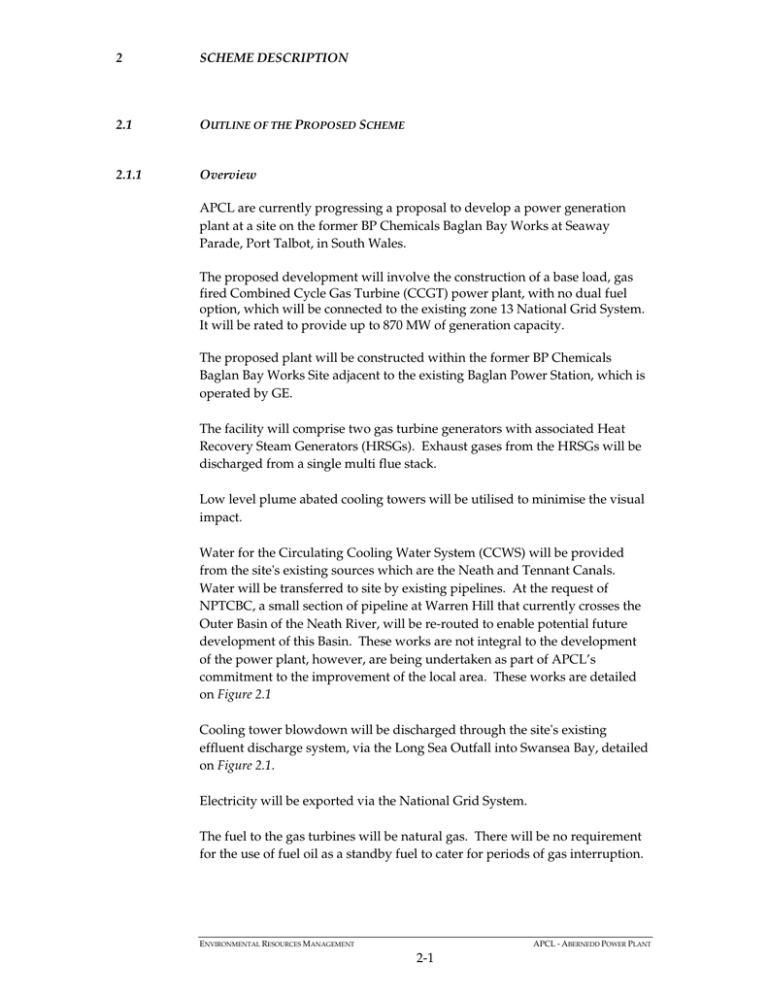

Water for the Circulating Cooling Water System (CCWS) will be provided

from the site's existing sources which are the Neath and Tennant Canals.

Water will be transferred to site by existing pipelines. At the request of

NPTCBC, a small section of pipeline at Warren Hill that currently crosses the

Outer Basin of the Neath River, will be re-routed to enable potential future

development of this Basin. These works are not integral to the development

of the power plant, however, are being undertaken as part of APCL’s

commitment to the improvement of the local area. These works are detailed

on Figure 2.1

Cooling tower blowdown will be discharged through the site's existing

effluent discharge system, via the Long Sea Outfall into Swansea Bay, detailed

on Figure 2.1.

Electricity will be exported via the National Grid System.

The fuel to the gas turbines will be natural gas. There will be no requirement

for the use of fuel oil as a standby fuel to cater for periods of gas interruption.

ENVIRONMENTAL RESOURCES MANAGEMENT

APCL - ABERNEDD POWER PLANT

2-1

Cooling

Water

Pipeline

Existing

Effluent

Discharge

System

.

300

Metres

KEY:

Site

New Pipeline

Existing Pipeline

Redundant Pipeline

Existing Pipeline to be Upgraded

CLIENT:

APCL

SIZE:

A4

ERM

Llandarcy House

11A The Courtyard

Llandarcy

Swansea Bay, SA10 6EJ

Tel: 01792 814907

Fax: 01792 817396

SOURCE: Reproduced from Ordnance Survey digital map data. © Crown

copyright, All rights reserved. 2008 License number 0100031673.

PROJECTION: British National Grid

TITLE:

Figure 2.1

Associated Pipelines

DATE: 29/05/2008 CHECKED: PW

PROJECT: 0064142

DRAWN: CO

SCALE: 1:15,000

DRAWING:

APPROVED: SD

Associated_Pipelines.mxd

REV:

© ERM This print is confidential and is supplied on the understanding that it will be used only as a record to identify or inspect parts, concepts or designs and that it is not disclosed to other persons or to be used for construction purposes without permission.

1

File: 0064142BaglanBayGIS\mxds\NewB oundary_ES\Associated_Pipelines.mxd

0

2.1.2

Proposed Structures

The key physical structures associated with the project are:•

•

•

•

•

•

2.1.3

a turbine hall containing the gas (GT) and steam (ST) turbine(s);

a Heat Recovery Steam Generator (HRSG) associated with each GT power

train;

a single concrete multi-flue stack;

low profile plume abated cooling towers (LPPACT’s);

an outdoor switchyard and

an administration building, control room, amenities, stores and

workshops.

Power Plant Site

The site for the proposed power plant is located within the NPTCBC

administrative area, to the south of the existing GE power plant which is a

nominal 500 MW CCGT power plant, presently owned and operated by GE.

The proposed power plant will be contained within the larger and former BP

Chemicals Works site at Baglan. The site is predominantly flat and comprises

circa 600 mm of blast furnace slag and chippings overlaying circa 25 m of sand

with boulder clay “rockhead”. The former BP Chemicals plant and buildings

have now been demolished leaving a few electrical substations, and the

former internal site roads and infrastructure. Most of the former buried

services have been isolated and made redundant but there remains some

electrical and Towns Water and other service infrastructure which may

require some minor relocation as part of this proposed development. Such

works do not impact any operations external to the former BP Chemicals site.

The site has excellent road access from the M4, at Junction 41 and then via the

Baglan Energy Park adopted highway. This is the same route that was used

during the construction of the existing GE Power Station.

Figure 2.2 shows the area proposed for the CCGT site, Figure 2.3 shows a basic

plant layout.

ENVIRONMENTAL RESOURCES MANAGEMENT

APCL - ABERNEDD POWER PLANT

2-3

CLIENT:

Site Footprint

APCL

SIZE:

TITLE:

A4

ERM

Llandarcy House

11A The Courtyard

Llandarcy

Swansea Bay, SA10 6EJ

Tel: 01792 814907

Fax: 01792 817396

SOURCE: Unspecified

PROJECTION: British National Grid

© ERM This print is confidential and is supplied on the understanding that it will be used only as a record to identify or inspect parts, concepts or designs and that it is not disclosed to other persons or to be used for construction purposes without permission.

Figure 2.2

Site Footprint

DATE: 29/05/2008 CHECKED: SL

PROJECT: 0064142

DRAWN: CO

SCALE: NTS

APPROVED: SD

DRAWING:

SiteFootprint2.2.mxd

REV:

0

File: 0064142BaglanBayGIS\mxds\NewBoundary_ES\SiteFootprint2.2.mxd

KEY:

FIGURE 2.3

Plant Layout

2.2

PROCESS DESCRIPTION

2.2.1

Introduction

A CCGT plant is a highly efficient mode of generating electricity. This higher

efficiency is attained primarily through the combination of a gas turbine with

a steam turbine to recover and use the exhaust heat generated by the former.

The main process stages of the proposed CCGT are explained below.

2.2.2

Gas Turbines

Natural gas, supplied from the existing Transco network, will be used as the

fuel source to supply the gas turbines contained within the enclosed

machinery hall. Each of the gas turbines will draw combustion air from the

atmosphere via intake filters to remove particulate matter that might

otherwise damage the internal components of the machine. Fuel gas, mixed

with combustion air, is injected into the combustion chamber of the gas

turbine, where it burns to produce hot, high pressure, gases. These are

expanded through a power turbine which drives the compressor and electrical

generator.

The gas turbine power plant generally comprises a turbine compartment,

accessory compartment and inlet and exhaust systems. The turbines are

equipped with electric starting motors, or static frequency converters, and are

located indoors to reduce the noise emanating from the site. The exhaust

arrangement includes silencing and ducting. Combustion gases exit from the

exhaust system to the HRSG(s).

2.2.3

Heat Recovery Steam Generators

An HRSG is provided for each gas turbine. Each of the units comprises

separate steam circuits, complete with all necessary integral pipework,

equipment and instrumentation required for the safe and efficient operation of

the plant. The exhaust gases from the gas turbines pass through the HRSGs

where heat is extracted to raise and superheat steam. Exhaust gases are

subsequently discharged to atmosphere via a single multi flue stack.

The height of the stack required to ensure adequate dispersal is assumed to be

of the order of 90m, but the precise height will be agreed with the

Environment Agency during the PPC process. For the purposes of this EIA,

the stack height has been assessed at 90m.

2.2.4

Steam Turbines

Steam from the HRSG is conveyed to the steam turbine which is provided

with multiple admission points, one for each pressure level. The turbine itself

will probably comprise a high pressure cylinder and double flow, low

pressure cylinders. This steam turbine subsequently drives an electrical

generator similar to those driven by the gas turbines.

ENVIRONMENTAL RESOURCES MANAGEMENT

APCL - ABERNEDD POWER PLANT

2-7

The steam discharged from the steam turbine is condensed and then

recirculated back to the HRSG and reconverted back to steam.

2.2.5

Condenser Cooling

Cooling for the steam turbine condensers will be provided by a circulating

water system incorporating two banks of hybrid cooling towers.

2.2.6

Water Source and Discharges

The cooling water for the power plant will be provided from the site's existing

supply: the Neath and Tennant Canals. All appropriate abstraction licenses

will be obtained by APCL prior to operation. Some works will be required to

the existing pipeline from the Neath Canal. These will include upgrading and

re-routing of a short section of the pipeline (refer to Figure 2.1).

Expelled cooling water will be discharged into Swansea Bay via the existing

Long Sea Outfall. Minimal connection works only will be required to the

existing outfall and all licenses will be agreed with the Environment Agency

Wales (EAW) prior to discharge.

2.2.7

Water Demineralisation Plant

The condensed steam is returned via a deaerator and feed system, back to the

waste heat recovery boiler in a closed loop steam cycle. System losses will be

replenished by high purity make-up water produced by an on-site

demineralisation plant using towns water as the raw feed.

Treated effluents from this demineralisation unit will be neutralized and then

disposed to process drain.

2.2.8

Fuel Supplies

The proposed plant will utilise the existing buried underground natural gas

pipeline from national Grid Transco’s pipeline on the mountain above Tonna

to the north west of the site, to transport gas to the Baglan site. Natural gas is

a clean fuel and does not produce the particulate emissions associated with

burning coal or oil; consequently flue gas cleaning equipment is not required.

Natural gas will be supplied directly to an on-site gaseous fuel conditioning

area, where the pressure is regulated to match that required by the gas

turbines.

2.2.9

Electrical Power Transmission

The plant will be connected into the existing 275 kV National Grid, substation

on the Baglan Site. There may be a requirement for new overhead power lines

but this is outside the scope of this EIA and should this be required, any

potential impacts will be assessed separately as part of a Section 37 of the

ENVIRONMENTAL RESOURCES MANAGEMENT

APCL - ABERNEDD POWER PLANT

2-8

Electricity Act, 1989, Application. However, to support this EIA, an initial

desk based assessment has been undertaken in order to provide an indication

of the likely significant environmental impacts of these associated works,

which is reported in Chapter 14 of this ES.

2.2.10

Materials Handling Utilities and Infrastructure

During normal operation a range of products will be delivered to the power

plant. Natural gas and canal water will be imported by pipelines and others

(such as machinery lubricating oil, spare parts) will be delivered by road in

drums and packages. Most of these shipments will be stored in an amenities

and storage area.

The following utility systems will be provided:

•

Water to supply the demineralisation plant will be supplied by a raw

water pipeline from the towns water system.

•

Cooling water make-up will be drawn from the Neath and Tennant

Canals, via the existing pumping stations.

•

The fire extinguishing system for the proposed CCGT power plant will

consist of:

•

•

•

•

a hydrant main;

a wet pipe sprinkler system over the large transformers, the steam

turbine house, stores areas, and other possible oil leakage areas;

a carbon dioxide (CO2) system in electrical equipment rooms; and

a CO2 system in the gas turbine compartments.

Areas with no extinguishing systems will be fitted with an automatic fire

annunciating system, and buildings will be appropriately located to facilitate

connections to on-site firewater mains with fire water piping for the use of the

local fire brigade.

2.3

EMISSIONS TO THE ENVIRONMENT

2.3.1

Air Emissions

The principal emission to the atmosphere will arise from the process of

natural gas combustion in the gas turbines: the main stacks will be sources of

oxides of nitrogen (NO and NO2) and carbon dioxide (CO2). Carbon dioxide

is the most important of the greenhouse gases and is believed to contribute

more than half to global warming effects. Gas combustion from a CCGT

power plant produces approximately 57% of the CO2 per unit of energy

generated when compared with coal combustion. This is due to the higher

thermal efficiency achieved by CCGT power plant and the greater specific

energy content of the gas.

ENVIRONMENTAL RESOURCES MANAGEMENT

APCL - ABERNEDD POWER PLANT

2-9

Plant emissions will comply with the requirements of the Environment

Agency Wales, as determined by the PPC process. Chapter 12, Air Quality

presents an assessment of the likely environmental impacts associated with

the current proposals.

2.3.2

Liquid Emissions

Cooling waters will be discharged through the Dwyr Cymru Welsh Water

(DCWW) existing pipeline which extends approximately 2 km offshore into

Swansea Bay. Such a discharge would be subject to approval through the PPC

licensing system, under the Pollution Prevention and Control Regulations,

2000.

Four other discharges will also arise as a result of the operational facility:

•

•

•

•

2.3.3

surface drainage water discharge from site;

foul drainage from sources such as sanitary waters;

neutralised effluent from the demineralisation plant; and

process water discharge from the water/steam circuits.

Solid Wastes

Solid wastes will arise during the construction and operation of the CCGT

power plant. Where appropriate these wastes will be collected and disposed

of by licensed waste disposal contractors.

2.4

PROJECT PHASING

The power plant will be constructed in two stages.

Stage 1 will comprise:

•

•

•

•

•

•

GT/Generator 1, HRSG 1, the steam turbine/generator, electrical and

mechanical balance-of-plant equipment and systems (part);

the fuel gas compressor, the fuel gas above ground installation (AGI);

the water treatment plant (part), raw and treated water storage tanks, the

cooling water systems;

GT Generator Transformer 1, electrical switchgear and electrical and

control systems (part), electrical substation works;

all buildings and site facilities including control room facilities; and

all sub-surface works including excavations, piling works, foundations,

civil and drainage systems works.

Stage 2 will comprise:

•

GT/Generator 2, HRSG 2, electrical and mechanical balance-of-plant

equipment and systems (balance);

ENVIRONMENTAL RESOURCES MANAGEMENT

APCL - ABERNEDD POWER PLANT

2-10

•

•

the water treatment plant (balance); and

GT Generator Transformer 2, electrical switchgear and electrical and

control systems (balance).

This ES reports the likely significant environmental impacts from both stages

of development.

The construction schedule for the new plant is dependant on the date when

National Grid can achieve the connection to the grid system and effect export

from the Baglan site. This connection date currently set as follows:

•

•

Stage 1 = 435MW October 2013 ; and

Stage 2 = 870MW October 2016.

Assuming an Autumn 2013 grid connection date, the indicative high level

project programme milestones for stage 1 will be:

•

•

•

•

•

•

•

•

main contract award – spring 2011;

site mobilisation – summer/autumn 2011;

ground preparation works – summer / autumn 2011

piling & foundation works – autumn 2011 to spring 2012;

installation & construction of Stage 1 plant and equipment – spring 2012

to summer 2013;

commissioning & testing - autumn 2013;

partial site demobilisation – autumn / winter 2013; and

Stage 1 plant in commercial operation – autumn 2013.

The total construction period for Stage 1 will be approximately 30 months.

Assuming an Autumn 2016 grid connection date, the indicative high level

project programme milestones for Stage 2 will be:

•

•

•

•

•

•

•

•

main contract award – spring 2011;

ground preparation works – summer / autumn 2011

piling & foundation works – autumn 2011 to spring 2012;

site remobilisation – summer/autumn 2015;

installation & construction of Stage 2 plant and equipment - autumn 2015

to summer 2016;

commissioning & testing - autumn 2016;

site demobilisation – autumn / winter 2016; and

Stage 2 plant in commercial operation – autumn 2016.

The total construction period for Stage 2 will be approximately 18 months.

Figure 2.4 depicts the project programme. As illustrated, the entire contractual

period for the project, from site mobilisation of Stage 1 to site demobilisation

of Stage 2, is 54 months.

ENVIRONMENTAL RESOURCES MANAGEMENT

APCL - ABERNEDD POWER PLANT

2-11

The major project activities are broken into the following phases.

•

Site preparation and preliminary work. This comprises land clearance,

levelling of the site earthworks, construction of the site roads,

installation of drainage system, temporary facilities for the main

contractors workforce, and construction of laydown areas and access

roads. A period of approximately six months is required for this phase

of work.

•

The main construction. This encompasses the laying of plant

foundations, erection of all above ground structures and installation of

plant. A period of approximately eighteen months is allowed for this

phase.

•

Commissioning and reliability tests. Independent commissioning tests

will be undertaken by the contractor to ensure the plant meets all

specifications. A period of approximately six months for each of the two

stages is allowed for this phase.

ENVIRONMENTAL RESOURCES MANAGEMENT

APCL - ABERNEDD POWER PLANT

2-12

Figure 2.4 Project Programme

STAGE

PROJECT TIMELINE

2011

2012

2013

2014

2015

2016

QTR 1 QTR 2 QTR 3 QTR 4 QTR 1 QTR 2 QTR 3 QTR 4 QTR 1 QTR 2 QTR 3 QTR 4 QTR 1 QTR 2 QTR 3 QTR 4 QTR 1 QTR 2 QTR 3 QTR 4 QTR 1 QTR 2 QTR 3 QTR 4

Main Contract Award (for both stages of build),

Site Mobilisation (for the first stage of build) and Ground Preparation

Works (for both stages of build),

Excavations, Piling, Foundation, Drainage, Civil and Building Works

(for both stages of build),

Installation and Construction of first stage plant and equipment,

Commissioning and Testing of first stage plant and equipment

Partial Site Demobilisation (leaving skeleton contractor's team on site)

Stage 1 plant and equipment in commercial operation

Site Remobilisation (for the second stage of build),

Installation and Construction of second stage plant and equipment,

Commissioning and Testing of second stage plant and equipment,

Site Demobilisation,

Stage 2 plant and equipment joins stage 1 plant and equipment in

commercial operation.

2.5

HEALTH, SAFETY AND HAZARDS ISSUES

2.5.1

Overview

The health and safety of the workforce and local population is considered by

both APCL and the various authorities to be of paramount importance in the

design, construction and operation of the plant. Hence, potential hazards

presented by the installation have been considered by APCL and appropriate

design measures will be taken and operating procedures will be written to

mitigate and manage any risk involved.

The developer's statutory responsibilities include ensuring the safe design of

plant and apparatus, and the provision and maintenance of safe and healthy

working conditions, equipment and systems of work for all of its employees,

and for the health and safety of other people who may be affected by its

activities. This responsibility arises from the requirements of various Acts of

Parliament and government regulations including the Health and Safety at

Work etc Act 1974, The Factories Act 1961, the Electricity Regulations 1908 and

1944, The Electricity Supply Regulations 1988, the Electricity Supply

Regulations 1988, Noise at Work Regulations 1989, the Offices, Shops and

Railways Premises Act 1963 and the Construction (Design and Management)

Regulations 2007.

2.5.2

Construction

During the design and construction of the CCGT power plant, the

Construction (Design and Management) Regulations 2007 will apply. Under

the requirements of the Regulations developers must:

•

appoint competent individuals to the roles of Planning Supervisor,

Designer and Principal Contractor, at the earliest point practicable;

•

prepare a Health and Safety Plan prior to commencement of

construction, which details potential risks and demonstrates competence

of the contractor;

•

provide the Planning Supervisor with information about the conditions

of the site.

The Planning Supervisor will be required to notify the Health and Safety

Executive (HSE) about the project, in writing, prior to commencement of

construction works.

2.5.3

Design

The design of the CCGT power plant will incorporate all required features

such as relief valves, alarms and trip systems. The Health and Safety

Executive (HSE) will be consulted as appropriate about the safety issues

associated with the proposed development.

ENVIRONMENTAL RESOURCES MANAGEMENT

APCL - ABERNEDD POWER PLANT

2-14

2.5.4

Material Storage

The quantities and type of substances and stores used on CCGT power plant

site will not require the site to be notified to the HSE under the Notification of

Installations Hazardous to Health Regulation 1982 or the Control of Industrial

Major Accident Hazards (CIMAH) Regulations, 1984. There will be no

significant storage of gas on site (1) . Suitable fire protection systems will be

provided as described and Fire Certification will be obtained from the Fire

Authority if required.

2.5.5

Fuel Supply

Natural gas will be supplied to the CCGT power plant site is via an existing

underground pipeline system. The pipeline complies with the Pipelines Act

1962, the Pipeline Safety Regulations (PSR) 1996 and where applicable the Gas

Safety (Management) Regulations 1996. Compliance with PSR will result in

the development of a Major Accident Prevention Policy (MAPP) whereas

compliance with PSR will involve the submission of a detailed Safety Case to

HSE.

A limited quantity of water treatment chemicals will be used at the plant.

These will be handled and stored in accordance with appropriate industry

standards. The water treatment chemical tanks will also be located in a

bunded area so that any spills will be contained.

2.5.6

Lighting

Suitable indoor and outdoor illumination will be provided throughout the

power plant to facilitate normal operation and maintenance activities as well

as for safety. Stand-by emergency DC lighting will be provided where

necessary.

2.5.7

Major Hazard

In itself the proposed power plant will not constitute a major hazard and will

not therefore be the subject of the CIMAH Regulations 1984.

(1) There may be limited quantities of bottled gases for welding,top up hydrogen for the generator cooling system, and CO

2 for the fire fighting systems

ENVIRONMENTAL RESOURCES MANAGEMENT

APCL - ABERNEDD POWER PLANT

2-15