1

LED Luminaire Lumen Maintenance – LM-80 Data

APPLICABLE MODEL: MILLENIUM SEMI-RECESSED EDGE™ MR13FFR SERIES WITH 20 WATT 4000K LED (20L40K)

The purpose of this document is to demonstrate that Kenall’s Millenium Edge MR13FFR follows current

industry standard procedures in reporting the expected lumen maintenance of the LEDs within the product

under normal operating conditions.

Lumen maintenance of the Philips-Lumileds LEDs used within this product is estimated by the following sets

of data:

In-Situ Product Testing of a representative product’s temperature characteristics (specifically the

measurement related to

LED junction temperature). For this product series, this product was evaluated by a UL Accredited DAP

laboratory to comply with UL8750 and UL1598 standards under an ambient temperature of 25°C (77°F). The

critical measurement concerning lifetime is

the LED temperature measurement point (TMPLED), which has been measured per Lumileds Application Brief

AB33.

LM-80 Test Results for the LED Package: Lumen maintenance evaluation of the LED source by its

manufacturer under compliance with IES LM-80-08 guidelines. The purpose of LM-80-08 is to determine

the lumen maintenance of an LED package, array or module after 6,000 hours of operation under specific

ambient temperature and electrical operating conditions.

The LEDs used within the luminaire are expected to maintain the lumen maintenance shown in the LM-80

testing if the LED temperature measurement point (TMPLED) is less than or equal to the temperature(s) specified

in the LM-80 test report for the corresponding drive current and the drive current in the luminaire is less than

or equal to the drive current specified in the LM-80 test report at the corresponding temperature or higher.

A summary of the lumen maintenance information is shown below:

LED Drive Current

700mA

In-Situ LED Temperature Measurement Point (TMPLED)184.1°C

Lumileds LM-80 Test Temperature285.0°C

Lumen Maintenance @ 6,000 hours/10,000 hours2

94.9% / 93.7%

Luminaire L70 Design Lifetime

50,000 hours

1

UL DAP Accredited laboratory test results of temperature corrected to 25°C ambient

2

Test result values from Lumileds LM-80 test results (Design Resource DR03 – 05/28/2010)

Please refer to attached excerpts from Design Resource DR03: LM-80 Test Report

Excerpt from Design Resource DR03: LM-80 Test Report

4. Operating cycle

4. Operating

cycle

LUXEON

Rebel LEDs

are driven with a constant direct current (DC).

LUXEON Rebel LEDs are driven with a constant direct current (DC).

5. Ambient conditions including airflow, temperature, and relative humidity

5. Ambient

conditions

including

airflow,

temperature,

relative

humidity

The

thermal chamber

has minimal

airflow. The

case temperature

withinand

the thermal

chamber

was characterized by mounting several thermocouples

Thea thermal

chamber stress

has minimal

The case temperature

within thepoint,

thermal

chamber

was characterized

by mounting

several

thermocouples

on

sample reliability

board airflow.

at the designated

thermal measurement

as shown

in Application

Brief, LUXEON

Rebel

Thermal

on

a

sample

reliability

stress

board

at

the

designated

thermal

measurement

point,

as

shown

in

Application

Brief,

LUXEON

Rebel

Thermal

Measurement Guidelines (AB33). In addition, several thermocouples were mounted in the air at a distance of 1.5 mm above the reliability stress

Measurement

Guidelines

In addition,

several thermocouples

were mounted

in the

a distance

of 1.5

mm above

the

reliability stress

board.

Then the

reliability(AB33).

stress board

was mounted

in the thermal chamber

and driven

at air

theatspecified

stress

condition.

The

thermocouple

board.

Then

the

reliability

stress

board

was

mounted

in

the

thermal

chamber

and

driven

at

the

specified

stress

condition.

The

thermocouple

readings were monitored. After the thermocouples reached thermal equilibrium, the thermocouple readings were data-logged and averaged

readings were

monitored.

Afterwithin

the thermocouples

reached

thermal equilibrium, the thermocouple readings were data-logged and averaged

together.

The relative

humidity

the oven was also

characterized.

together. The relative humidity within the oven was also characterized.

6. Case and ambient temperatures (ambient temperature measured 1.5mm above reliability stress board)

6. Case

ambient temperatures

(ambient

temperature

above

reliability

The

thermaland

characterization

results are summarized

in the table

below. In allmeasured

cases, both TS1.5mm

and TA meet

or exceed

the IES stress

LM-80-08board)

limits

TheTthermal

characterization

results

summarized in the table below. In all cases, both TS and TA meet or exceed the IES LM-80-08 limits

(i.e.

] 55°C

or 85°C, and that

TA]are

TS –5°C).

S

(i.e. TS ] 55°C or 85°C, and that TA] TS –5°C).

Required

Required

LM-80

Test

LM-80 Test

Temperature

Temperature

IF

IF

Actual

Actual

TS

TS

Actual

Actual

TA

TA

55°C

55°C

85°C

350 mA

350 mA

60°C

60°C

85°C

64°C

64°C

84°C

85°C *

108°C

108°C *

350 mA

350 mA

85°C

128°C

128°C

84°C

103°C

103°C

LM-80 Tests

LM-80

Tests

Actual

Actual

D[T

– TS]

A

D[TA– TS]

+4°C

+4°C

-1°C

-1°C

–25°C

–25°C

Actual

Actual

Relative

Relative

Humidity

Humidity

18%

18%

7%

7%

TBD

TBD

Average

Average

lumen

output

atlumen

6,000output

hours

at 6,000 hours

0.992

0.992

0.962

0.962

0.979

0.979

Average

Average

lumen

output

atlumen

10,000output

hours

at 10,000 hours

0.983

0.983

0.955

0.955

0.956

0.956

* Third temperature chosen by the manufacturer, and adjusted to meet –5°C TA – TS requirement.

* Third temperature chosen by the manufacturer, and adjusted to meet –5°C TA – TS requirement.

Additional

Additional

Test

Test

Temperature

Temperature

55°C

Additional Tests Provided

www.

kenall.com Actual

P:Additional

800-4-Kenall

847-360-1781

Tests F:

Provided

Actual

Actual

Actual

IF

IF

Actual

TS

TS

Actual

TA

TA

Actual

D[T

– TS]

A

D[TA– TS]

700 mA

69°C

73°C

+4°C

Actual

Relative

Relative

Humidity

Humidity

18%

1020 Lakeside

Drive Gurnee, Illinois

60031

Average

Average

Average

lumen

output

atlumen

6,000output

hours

at 6,000 hours

0.978

LM80TECHDATA-020912

Average

lumen

output

atlumen

10,000output

hours

at 10,000 hours

0.967

108°C *

350 mA

128°C

103°C

–25°C

TBD

0.979

0.956

* Third temperature chosen by the manufacturer, and adjusted to meet –5°C TA – TS requirement.

2

Additional Tests Provided

Additional

Test

Temperature

IF

Actual

TS

Actual

TA

Actual

D[TA– TS]

Actual

Relative

Humidity

Average

lumen output

at 6,000 hours

Average

lumen output

at 10,000 hours

55°C

85°C

700 mA

700 mA

69°C

92°C

73°C

87°C

+4°C

–5°C

18%

7%

0.978

0.949

0.967

0.937

55°C

1000 mA

71°C

80°C

+9°C

18%

0.955

0.945

7. Drive current of the LED light source during lifetime test

Specified in the tables.

8. Initial Luminous flux and forward voltage at photometric measurement current

See tables.

9. Lumen maintenance for data for each individual light source along with median value, standard deviation,

minimum and maximum lumen maintenance value for all of the light sources

See tables.

Design Resource DR03 (10/05/28)

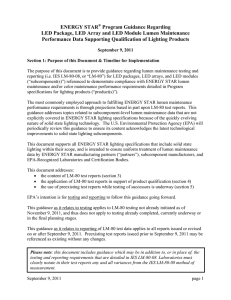

Lumen Maintenance Projection for

White LXM3-PWx1 LUXEON Rebel under these conditions

2

85°C, 0.7A ((Tjunction

j

112°C)) Normalized to 1 at 24 hours

1.2

*Philips Lumileds recommends

p

extrapolations

of 6x the test time

Normaliz

zed Light Ou

utput

1.1

1.0

Extrapolated data = –6.5% at 10,000 hours

0.9

35,000 hour

25,000 hour

0.8

ENERGY STAR 25,000 and 35,000

limits after 6,000

6 000 hours of stress

6x test time*

0.7

L70 = 65,000 hours

Ta within –5°C of Ts, in accordance with LM80.

0.6

0

6

1,000

10,000

100,000

1,000,000

Hours

©2010 Philips Lumileds Lighting Company. All rights reserved.

www. kenall.com

P: 800-4-Kenall

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031