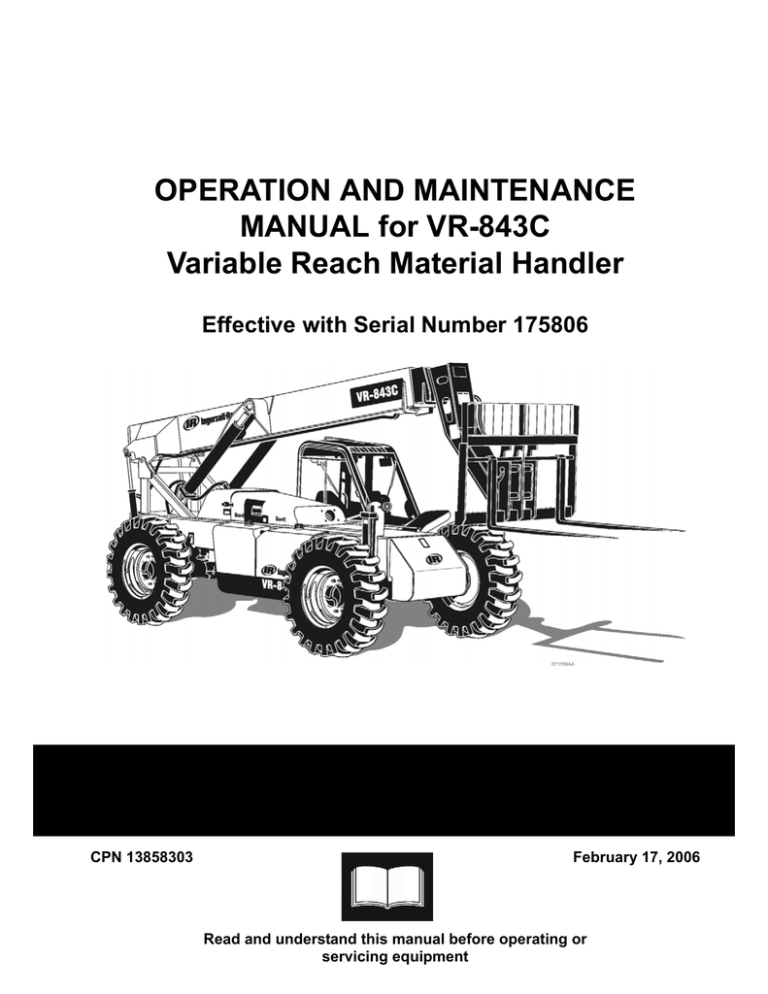

VR-843C Material Handler Operation & Maintenance Manual

advertisement