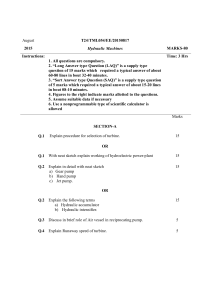

Specification Catalog

advertisement