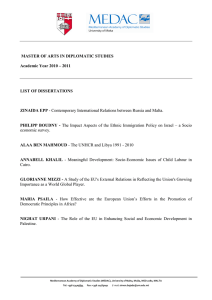

technical notices

advertisement