Non-intrusive sensing of air velocity, humidity, and temperature

advertisement

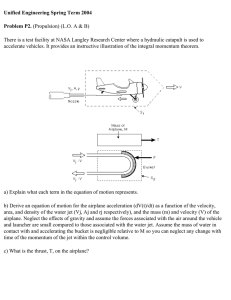

Non-intrusive sensing of air velocity, humidity, and temperature using TDLAS TDLAS: Tunable Diode Laser Absorption Spectroscopy Suhyeon Park Mechanical Engineering, Virginia Tech Advisor Dr. Lin Ma Aerospace and Ocean Engineering Mechanical Engineering Adjunct Virginia Tech Outline Introduction: Concept of TDLAS measurement Velocity measurement Temperature measurement and non-uniform distribution analysis Water concentration tomographic inversion College of Engineering 2 TDLAS for wind energy TDLAS sensor Real-time monitoring Research instrument • • • • Flow info Active control of wind turbines Velocity, humidity and temperature - simultaneous measurement Non-intrusive in-situ real-time monitoring without particle seeding Calibration-free accurate measurement Low cost, low maintenance College of Engineering 3 Fundamental theory of absorption spectroscopy Detector It() L Io () L aser 𝐼𝑡 (𝜈) 𝐼𝑜 • Beer - Lambert relation: 𝜏 𝜈 = • Measure 𝑘𝜈 and P to infer T and X : 𝑘𝜈 = 𝑓(𝑇, 𝑋, 𝑃) College of Engineering = exp[−𝑘𝜈 ⋅ 𝐿] 4 Principle of TDLAS measurement • 𝑇 – temperature : inferred from the shape of spectra (the relative absorption strengthen of a “cold” and a “hot” line) • 𝑋 – H2O concentration : inferred from the magnitude of the spectra after 𝑇) • 𝑉 – flow velocity : inferred from Doppler shift between two beams with an angle T=2379 K X=0.347 T=1647 X=0.190 Cold Line 1.379 mm College of Engineering Hot Line 1.333 mm 5 Outline Introduction: Concept of TDLAS measurement Velocity measurement Temperature measurement and non-uniform distribution analysis Water concentration tomographic inversion College of Engineering 6 TDLAS Doppler velocimetry setup 50 𝜃 Laser Diode 1343 nm 90 50 Coupler 50 Coupler 50 Laser Diode 1392 nm Photodiode 1 Coupler 10 Photodiode 2 MZI Interferometer Air Flow Schematic of H2O absorption velocity measurement • Tunable diode laser scans across optical frequency • Mach-Zehnder interferometer converts time series data into frequency spectrum • Two beams cross at angle 2𝜃 and Doppler shift is measured College of Engineering 7 TDLAS velocity measurement demonstrated in a simple duct y Laser Air Flow x Experimental setup of TDLAS velocity measurement College of Engineering Averaged velocity in the y direction 8 Measured Doppler shift by TDLAS Voigt Fitting Parameters Voigt 1 College of Engineering Voigt 2 y0, offset -1.2264E-03 -1.3770E-03 xc, center -1.6779E-03 -1.2582E-03 A, area 4.5947E-03 wG, Gaussian width -3.6193E-02 -3.4506E-02 wL, Lorenzian width 6.5980E-02 4.6043E-03 6.7691E-02 9 TDLAS measured velocity in agree with hot wire velocity • TDLAS velocity agrees well with “averaged” hot-wire velocity • “Averaging” (i.e., effects of flow non-uniformity) will be more thoroughly investigated in the future College of Engineering 10 Outline Introduction: Concept of TDLAS measurement Velocity measurement Temperature measurement and non-uniform distribution analysis Water concentration tomographic inversion College of Engineering 11 Ambient air temperature measurement Cold Laser Whole Range Hot Laser Whole Range 1.4 0.03 Simulation Measurement 1.2 TDLAS cold line 0.6 0.4 0.01 0.005 0 0 7175 7180 7185 Wavenumber(cm-1) -0.005 7190 TDLAS hot line 0.015 0.2 -0.2 7435 7440 7445 7450 Wavenumber(cm-1) TDLAS cold line Voigt Fitting 0.025 Measurement Voigt Fit 0.25 Absorbance 0.15 0.1 Measurement Voigt Fit 0.02 0.2 Absorbance 7455 TDLAS line Voigthot Fitting 0.3 0.01 • 0 0 Acold = 2.279 e-2 -0.2 cm-1 -0.1 0 0.1 Wavenumber (cm-1) College of Engineering Temperature sensing • 0.015 0.005 0.05 -0.05 Laser controller setting: • Diode temperature Tcase,cold = 27.2°C Tcase,hot = 26.2°C • Drive current control Vmod = 1.7 Vpp, ramp signal 0.02 0.8 Absorbance Absorbance 1 Identification of target lines Simulation Measurement 0.025 Room condition T = 23°C Measured temperature TM = 25°C (error = +2 K) Ahot 1.307 e-3 cm-1 0.2 -0.005 -0.4 -0.2 0 0.2 Wavenumber (cm-1) 0.4 12 Thermocouple measurement of flame temperature McKenna Burner and flame temperature measurement • Thermocouple was manually traversed through a stable flat flame from a McKenna burner 1400 • McKenna burner flame temperature was about 1200 °C. Temperature (°C) 1200 1000 800 600 400 200 0 0 College of Engineering 50 Position (mm) 100 13 Setup to demonstrate non-uniform temperature distribution • TDLAS measurement was conducted for premixed burner flame Detector Hot section Beam path McKenna Burner Laser Non-uniform temperature distribution setup College of Engineering • Goal: To see if TDLAS can resolve the non-uniform temperature and water concentration in the laser beam path – Hot section: flame – Cold sections: ambient air 14 Line-of-sight TDLAS measurement of Flame Temperature Line Strength - Temperature Relation 0.05 2 • TDLAS measured temperature was 936 °C Acold Ahot Ratio Absorbance Shot/Scold Signal ratio • Discrepancy is due to temperature non-uniformity in the beam path T 0 500 1000 1500 2000 Temperature (K) T = 1209 K = 936 °C College of Engineering 2500 0 3000 • Possible solutions include nonuniform analysis or tomographic inversion. 15 Flame temperature distribution by TDLAS non-uniform analysis TC TDLAS 1800 1600 1400 1200 T (K) Case 1 TDLAS 1460 K TC 1489 K • Non-uniformly distributed temperature is found by thermocouple (TC) and TDLAS measurement 1000 800 600 400 200 0 20 40 60 80 x (mm) TC TDLAS 1800 1600 1400 1200 T (K) Case 2 TDLAS 1587 K TC 1588 K 1000 800 • TDLAS measured temperature distribution agrees with TC measurement 600 400 200 0 20 40 60 80 x (mm) College of Engineering 16 Non-uniform fitting procedure Temperature Distribution • Fitting procedure demonstrated to find T1, X1, T2, X2 in hot section and cold sections Temperature (K) T1 6 cm T2 T2 • Valuable for practical implementation 0 0 – Practical flows are non-uniform – Undesirable/difficult to mount sensors near hot flows Position (cm) Side View Flame Collimator College of Engineering McKenna Burner Detector 17 Example results from the fitting procedure TDLAS absorption spectrum T1 = 1587 K, X1 = 0.117 0.1 0.14 Measurement Non-uniform Uniform 0.12 0.08 0.07 Absorbance 0.1 Absorbance Measurement Non-uniform Uniform 0.09 0.08 0.06 0.06 0.05 0.04 0.03 0.04 0.02 0.02 0 0.01 7185.4 7185.5 7185.6 Frequency, cm-1 7185.7 7185.8 0 7444.1 7444.2 7444.3 7444.4 Frequency, cm-1 7444.5 • Our method exploits the shape (i.e., all the data points on the absorption lines) to obtain distribution information in nonuniform flows College of Engineering 18 Outline Introduction: Concept of TDLAS measurement Velocity measurement Temperature measurement and non-uniform distribution analysis Water concentration tomographic inversion College of Engineering 19 TDLAS setup in high speed jet measurement Traverser Jet Sensors Lasers Laser controller TDLAS setup installed at the high speed jet facility Detecter + IS • Laser beams cross at the jet for TDLAS velocity measurement with Doppler effect Collimator Beam 1 • Sensors are installed on a vertical traverser Beam 2 Detecter + IS • TDLAS measurement system is installed for high speed jet measurement Jet flow Collimator TDLAS sensors located at the jet College of Engineering 20 Water density of high speed jet obtained by traversing TDLAS -3 3 x 10 • Line-of-sight averaged water concentration measured by traversing the TDLAS sensor Jet flow 2.8 XL (A.U.) 2.6 2.4 • Conditions 2.2 Ambient air Ambient air 2 1.8 -6 -4 -2 0 2 Vertical Position(cm) 4 6 – Ambient air: 25 °C, X = 0.010 – Compressor supplied air: 17 °C, X = 0.008 – Traversing step : 0.4 cm TDLAS measurement in the high speed jet at Mach 0.65 College of Engineering 21 Projection of non-uniform distribution X1 Distribution 5 cm X1 X2 0 r y X1 Front View X2 • Water density projection should be reconstructed to distribution by tomography X1 Jet flow Collimator • TDLAS measurement by traversing is a projection of non-uniform distribution Detector Projection 0 College of Engineering y 22 Introduction to Abel inversion (Tomography in 1D) l1,1 r l1,2 l2,2 l3,3 l2,3 l1,3 ... X3 X = A-1P X2 X1 • Abel inversion is used in axially symmetric geometry • The jet is divided into layers with different water density (X1, X2, X3 ...) • Distribution can be obtained from TDLAS measured projection by Abel inversion X - Distribution A - Geometry P - Projection College of Engineering 23 1D tomography applied to TDLAS jet measurements -3 16 x 10 Reconstructed X (A.U) 14 • Abel inversion is applied to TDLAS jet measurements Jet flow 12 10 8 • Spatial distribution of water density in the jet is obtained 6 4 2 Ambient air Ambient air 0 -2 -6 -4 -2 0 r (cm) 2 4 6 Spatial distribution of water density in the high speed jet at Mach 0.65 College of Engineering 24 Conclusion • TDLAS measurement of temperature, velocity, water concentration was demonstrated simultaneously • Non-intrusive instantaneous measurement capabilities of TDLAS sensor can be utilized in research facilities and practical monitoring system of wind energy College of Engineering 25 Thanks ! Suhyeon Park Department of Mechanical Engineering Virginia Tech, Blacksburg, 24060, VA Tel: (540)750-1559 Email: spark11@vt.edu College of Engineering 26