h-beam marking station

advertisement

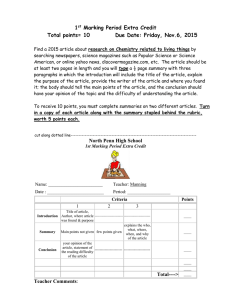

H-BEAM MARKING STATION Engineering traceability. H-BEAM MARKING STATION GENERAL DESCRIPTION Main advantages This equipment is intended to mark beams using ink-jet technology as they exit the straightening process. High visibility The equipment is based on a “retractile pneumatic moving device” for the single or double straightening machine. High flexibility regarding the marking content due to ink-jet digital programing A different mechanical design is used for multiple beam straighteners. Fast writing at the straightening process The equipment includes all mechanical and electrical protections to be installed into the factory’s security plan. The equipment is designed to be integrated on the factory’s PLC network to work on an automatic way with remote access. The equipment is designed to work on a non-attended way, except for the recommended preventive maintenance operations. Low maintenance High reliability due to a heavy duty construction Reduces traceability risks of fallen labels Increase of Overall Equipment Availability (OEA) Decrease of TBF SCOPE OF SUPPLY Main features A standard single H-Beam Marking Station includes Product temperature range Up to 100º C › A retractile pneumatic device to move the print head close to the beam and stay rolling over maintaining a constant printing distance. › The safety enclosure for human access control. › A control cabinet including PLC, touchscreen HMI. › A REA JET inkjet equipment (normally a 16 nozzle print head model). › A REA JET recirculating ink supply (special for pigmented inks). Paint White colour (others on request) Print speed Up to 10 m/sec Print heigh 27 - 67 mm Number of text lines 1 or 2 A standard multiple H-Beam Marking Station includes Number of characters On request › A fixed heavy duty steel plate protection on top of the beam’s conveyor. Power supply 3 x 400 V, 50Hz (other voltage possible) › Two stainless steel protective rotating cassettes containing the print heads, as well as the moving devices to center the print heads on the beams’ positions. Power consumption Approx. 10kVA › A control cabinet including PLC, touchscreen HMI to control marking station. › A REA JET inkjet equipment (normally with several 7 nozzle print heads). › Several ink supplies. Non included › The necessary civil works at the area to install the robot cell. › The power, data, or pneumatic supply lines. › The print go signal (beam presence) as well as a channel of pulses from the straightening machine’s speed. Options › A blowing device for cleaning the steel husk or water from the surface Pneumatic supply Min. 5 bar, filtered & drained Pneumatic consumption Max. 0.5 m3/min including cooling, husk blowing & marking Data network RS-485, Profibus, Profinet… Erregeoiana, 2A-2B 20305 Irun - Spain +34 943 631 577 info@smarktec.com www.smarktec.com