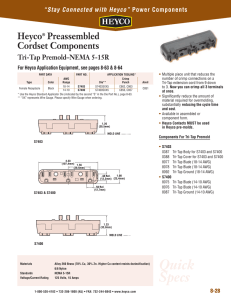

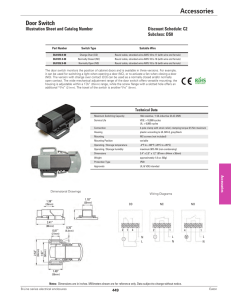

Wire Termination

advertisement