Oracle ® Complex Maintenance, Repair and Overhaul

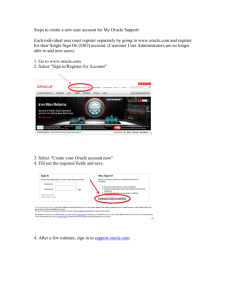

advertisement