MASTER`S THESIS UAV Stabilized Platform

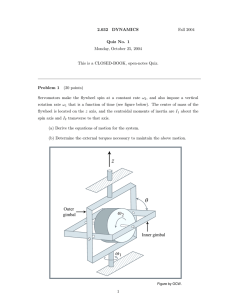

advertisement