APPROXIMATE MODEL OF THERMAL RESIDUAL STRESS IN AN

advertisement

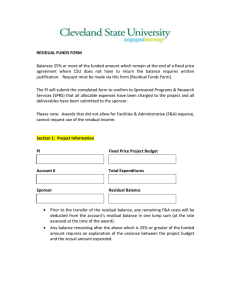

Journal of Thermal Stresses, 25:523±538, 2002 Copyright # 2002 Taylor & Francis 0149-5739 /02 $12.00+.0 0 DOI: 10.108 0=01495730290074270 APPROXIMATE MODEL OF THERMAL RESIDUAL STRESS IN AN INJECTION MOLDED PART X. Zhang, X. Cheng, and K. A. Stelson Department of Mechanical Engineering University of Minnesota Minneapolis, Minnesota, USA M. Bhattacharya and A. Sen Department of Biosystems and Agricultural Engineering University of Minnesota Minneapolis, Minnesota, USA V. R. Voller Department of Civil Engineering University of Minnesota Minneapolis, Minnesota, USA A description and model of the thermally induced residual stress that forms in a ``platelike’’ injected molded polymer part is outlined. A linear heat balance integral (LHBI) temperature pro®le approximation and the concept of a virtual adjunct mold (VAM) is used to arrive at an approximate algebraic model that, upon providing material properties and processing conditions, gives an immediate evaluation of the residual stress through the plate thickness. Results obtained with this model are in very close agreement with a full numerical solution and agree closely with experimental measurements made on a range of starch-based biodegradabl e polymer samples. Injection molding is used in the fabrication of a wide range of plastic products. In the injection-molding process, molten polymer is injected into a mold and then is packed under pressure, solidi®ed, and then cooled to a uniform temperature. Figure 1 schematically illustrates the solidi®cation stage of a ``platelike’’ part. Injection molding introduces residual stresses, a stress state that exists in the bulk of a material without application of any external load, in the ®nal product [1, 2]. It is important to know the residual stress state of the part to predict its performance under load. Depending on the situation, residual stresses can be either detrimental or Received 10 July 2001; accepted 10 November 2001. This work was supported by the NSF Division of Design, Manufacturing and Industrial Innovation, under grant DMI 97-00126 . Address correspondence to Professor Vaughan Voller, Department of Civil Engineering, University of Minnesota, 500 Pillsbury Drive S.E., Minneapolis, MN 55455. E-mail: volle001@umn.edu 523 524 X. ZHANG ET AL. Figure 1. Schematic of solidi®cation of an injected molded plate. bene®cial. Compressive residual stress on the surface can prevent the opening up of cracks, thereby increasing the fatigue life. Conversely, when the stresses due to external loads are added to the residual stress, plastic yielding will begin at a lower load. An asymmetric mold wall temperature distribution will cause asymmetric residual stresses; and if the part is not sti enough, it will warp after its ejection from the mold [3]. The aim of this article is the development of a simple approximate model for predicting the residual stresses in injected-molded parts fabricated from starch-based biodegradable polymers. In a general case the residual stress in an injected molded part could include a number of contributions , including i. Flow-induced residual stress, generated as a result of shear, normal, and extensional ¯ows during processing [4, 5]; ii. Packing stress, resulting from the high pressures imposed during packing; iii. Thermal stress, formed during solidi®cation and cooling [6±8]. As a general rule of thumb, for most polymers of interest, the thermal residual stresses dominate the ¯ow-induced stresses. Further, packing pressure and packing time may not have a signi®cant e ect; for example, in starch-based polymer it has been shown that the packing pressures account for approximately 5% of the observed residual stress [6]. Hence, the work in this article will only consider thermalinduced residual stresses that form in injection-molded polymer parts. STRESS IN AN INJECTION MOLDED PART 525 In the ®rst instance, a description of the mechanisms that lead to a thermally induced residual stress is provided and the governing equations of a standard model are outlined. In a complete treatment, the standard model requires the coupled solution of a solidi®cation heat transfer and stress equilibrium equation, a set of calculations that can be relatively complex. In this work, a simple thermal treatment that approximates the evolving thermal ®eld by a linear pro®le is proposed. This simple treatment leads to an explicit expression for the residual stress distribution through a platelike part. This approximate model is the key result of the article. The article concludes with a demonstration of the proposed approximate model via the comparison with full numerical treatments and experimental measurements. A DESCRIPTION OF RESIDUAL STRESS FORMATION IN A PLATE Consider a thin plate part cooled from its edges; see Figure 2. As a ¯uid layer solidi®es, a so-called ``¯ow-strain’’ is initiated [7]. This strain occurs, under hydrostatic stress, at the point of solidi®cation, where the semisolid layer deforms to attach to the existing solid. The interaction between the development of the strain, due to thermal shrinkage, and the initiation of the ¯ow-strain leads to a nonzero throughthickness stress distribution when the sheet is cooled to a uniform temperature. A simple description based on Figure 2, which models the part as a set of lamella, can throw more light on the key mechanisms. At the early stages of cooling, a solid layer forms next to the cooling surface and it is reasonable to assume that the strain in this solid layer, a decreasing function of time, is uniform through the thickness. As a new ¯uid lamella solidi®es and joins the solid, it needs to undergo a strain from its Figure 2. Schematic of thermal residual stress formation. 526 X. ZHANG ET AL. undeformed initial state. This strain, referred to as the ¯ow strain occurs under negligible stress, takes a value of zero at the cooled surface and is a monotonically increasing function of solid thickness alone. Since the ¯ow strain will be larger in the center of the part, the additional e ect of thermal shrinkage will lead to a situation where, if taken in isolation, the deformation of a lamella from the center of the part will be larger than that of a lamella taken from the edge of the part. Hence, the net result, when the lamella are integrated into the part and the condition of a uniform solid strain is imposed, is to place lamella at the part center in tension and those at the part edge in compression, behavior that matches the reported observations [7, 8]. A THERMAL-ELASTIC RESIDUAL STRESS MODEL The thermal-elastic residual stress model presented here closely follows the work of Osswald and Menges [7]. Since injection-molded parts are generally thin, we simplify the analysis to a thin plate of thickness 2b, which is cooled from both sides. If symmetry is assumed, the coupled mechanical and thermal analysis can be carried out using a one-dimensional model in the half thickness, 0 µ z µ b; see Figure 1. At some instant of the cooling process, three regions in Figure 1 can be identi®ed: i. A liquid region that is strainfree and stressfree; ii. A thin layer undergoing solidi®cation at temperature Ts. This layer undergoes volume contraction and ¯ow resulting in a ``¯ow strain,’’ ev, which can also be referred to as a ``viscous strain.’’ It is assumed that this strain occurs under hydrostatic stress and is frozen in to the solid layer and, hence, is a function of space alone. iii. A full solid region. As the full solid region cools, a thermal strain, eth = b(T(z; t) – Ts ), is formed, where b is the thermal expansion coe cient. Under the assumption that the total strain, e(t), is, at a given instant in time, uniform across the plate thickness these observations lead to the expression for the total strain as a function of time e(t) = ee (z; t) ‡ b(T(z; t) – Ts ) ‡ ev (z) (1) where ee is the elastic strain. In order to make forward progress from Eq. (1) a method for evaluation of the ¯ow strain, ev (z), is required. From Hooke’s Law, assuming that Poisson’s ratio and Young’s modulus are constants, the stress in the solid layer, 0 µ z µ zs , is given by s(z; t) = E (e(t) – b(T(z; t) – Ts ) – ev (z)) 1– v Further, equilibrium requires that the integral Z zs s(z; t) dz = 0 0 (2) (3) STRESS IN AN INJECTION MOLDED PART 527 Combining Eqs. (2) and (3) gives Z zs [e(t) – b(T(z; t) – Ts ) – ev (z)] dz = 0 (4) 0 which upon manipulation and integration of the total strain gives 1 e(t) = zs Z zs [b(T(z; t) – Ts ) ‡ ev (z)] dz 0 (5) At the solidi®cation front, z = zs , the thermal and elastic strains are zero; and by Eq. (1), e(t) = ev (z),which means that Eq. (5) can be written as ev (zs ) = 1 zs Z zs 0 [b(T(z; t) – Ts ) ‡ ev (z)] dz (6) Assuming no relaxation, this ¯ow strain is frozen in place and will not change. Hence, if information on the evolving transient thermal ®eld, T(z; t), and location of the solidi®cation front, zs (t), are provided, Eq. (6) can be integrated at given values of zs to determine the ¯ow strain pro®le, ev (z). This calculation needs to be continued up to when the midplane, z = b, becomes solid, at which point the ¯ow strain pro®le will be fully determined. From the calculated ¯ow strain pro®le, ev (z), the total strain, and the residual stress distribution, when the plate has cooled to room temperature, Tf , can be found from the expressions etot = 1 b Z b 0 [b(Tf – Ts ) ‡ ev (z)] dz (7) and s(z) = E [etot – b(Tf – Ts ) – ev (z)] 1– v (8) respectively. Numerical Solution The transient temperature ®eld, T(z; t), and location of the solidi®cation front, zs, needed in Eq. (6) can be determined numerically. For semicrystalline polymers a model can be based on an enthalpy formulation [9, 10] r @H @2 T = k 2 @t @z (9) where the enthalpy H = cp T ‡ gL, L is the latent heat of the polymer. Cp is the speci®c heat, k the thermal conductivity, r the density, and g is the liquid fraction 528 X. ZHANG ET AL. taking a value of zero in the solid and one in the liquid. Upon introducing the dimensionless variables z¤ = z b t¤ = T – Ts Ts – Tf cp (Ts – Tf ) hb St = Bi = L k kSt t T¤ = r cp b2 H ¤ = StT ¤ ‡ g (10) where h is the convective heat transfer coe cient at the surface z = 0, the governing equation becomes @H ¤ @ 2 T ¤ = @t¤ @z¤ subject to the boundary conditions ­ @T ¤ ­ ­ = – Bi(T ¤ ‡ 1) @z¤ ­ z= 0 and (11) ­ @T ¤ ­ ­= 0 @z¤ ­ z= b (12) The key dimensionless groups in the preceding equation are the Stefan number, St; the ratio of sensible to latent heat, which controls the phase change; and the Biot number, Bi, the ratio of convective heat removal to heat conduction, which controls the cooling. Note that the value of the heat transfer coe cient h is not strictly a constant as assumed here, but a function of time, controlled by interface conditions between the mold and part. The choice of a constant h is justi®ed upon noting that (i) the inclusion of a time-dependent heat transfer coe cient, assuming that reliable information is available, would greatly complicate the analysis in any modeling e ort; and (ii) comparisons with experiments (see results that follow) indicate that reasonable residual stress distributions can be predicted using a constant representative value of h. Equations (11) and (12) can be readily solved using, for example, an explicit enthalpy scheme [10] HInew = HI ‡ Dt [TI– 1 – 2TI ‡ TI‡ 1 ] D z2 (13) where I is a node counter on a space grid with uniform step D z; D t is a time step; the superscript new refers to values at the new time level; and, for presentation convenience, the ¤ superscript has been dropped. In a given time step the solution of Eq. (13) will provide an updated nodal enthalpy ®eld. The corresponding updated temperature ®eld follows on setting 8 H– 1 > < St T= 0 > :H St H>1 (14) H<0 STRESS IN AN INJECTION MOLDED PART 529 The time at which the solidi®cation front reaches node I, that is, zs = ID z, is given when the nodal enthalpy HI = 0.5. At this point the current nodal temperature distribution can be used in a numerical integration of Eq. (6) to obtain a corresponding nodal distribution for ev(zs). These nodal values can subsequently be used to calculate the residual stress pro®le through the part thickness. RESULTS FROM NUMERICAL SOLUTION The aim of this article is to arrive at a closed-form approximate model for prediction of the residual stress across the part thickness. This is seen as an alternative to the numerical solution presented previously. Intermediate results from the numerical solution, however, are needed to guide the development of the approximate model. These results are presented in this section. Transient residual stress pro®les, predicted with the numerical solution, at different times, corresponding to the property data given in Table 1, are shown in Figure 3; these pro®les have a good agreement with the results presented by Eduljee et al. [11]. Figure 4 shows three numerical predictions of the residual stress at room temperature. Between each prediction, the value of the Stefan number is changed by a factor of about 10 by increasing the latent heat value. It is noted that this change does not have a signi®cant impact on the predicted level of stress; a factor-of-sixty change in the value of the latent heat produces a maximum stress change less than one half. Thus it can be concluded that residual stress predictions with the thermalelastic model outlined previously are relatively insensitive to changes in the latent heat. This is a very worthwhile observation since the value of the latent heat in a semicrystalline polymer is di cult to determine [7]. Table 1 Material data for the starch-based polymer Material Data Symbol Value Part half thickness Young’s modulus=(1-Poisson’s ratio) 70% starch, 50% starch, 30% starch Thermal expansion coe cient (average) Thermal conductivity (average value) Final temperature Solidi®cation temperature Density (average value) Speci®c heat Heat transfer coe cient (average value) b E=(1– v) 5 mm 2163 MPa, 1435 MPa, 837 MPa b 4.87 £ 10 – 5¯ C– 1 K 0.25 w=m=¯ C Tf Ts r Cp h 20¯ C 115 ¯ C 1273 kg=m3 1674 J=kg=¯ C 1000 W=m2=¯ C 530 X. ZHANG ET AL. Figure 3. Residual stress distribution at three di erent times (70% starch). In interpreting the stress distribution in Figure 4, and later results of this article (e.g., Figures 5 and 9), it is important to note that, due to the requirement that stresses be in equilibrium, the area under a residual stress curve needs to be zero. A given curve represents a balance between compressive stresses at the part surface and Figure 4. Residual stress predictions at di erent Stefan number (changed by L). STRESS IN AN INJECTION MOLDED PART 531 Figure 5. Residual stress predictions at di erent Biot numbers (70% starch). tensile stresses at the part center. Since the residual stress curves are typically parabolic in shape, this results in curves, representing di erent conditions, crossing over each other at about the same point. Unlike the latent heat value in the Stefan number, the value of the Biot number a ects the residual stress ®eld. With a large Biot number, heat is rapidly removed from the surface, resulting in high residual stresses. As the Biot number decreases, the rate of heat removal slows and the residual stress is reduced [6]. Figure 5 shows the stress ®elds resulting from di erent choices of Biot number. The di erence in stress levels is very clear. Figure 6 shows, for two di erent Biot numbers, the temperature pro®les through the part thickness for various locations of the solidi®cation front. Note the relative straight nature of the pro®le in the solid region. Figure 6. Temperature pro®les at di erent solidi®cation thickness at two Biot numbers. 532 X. ZHANG ET AL. THE LHBI-VAM APPROXIMATE SOLUTION Observations of results obtained with the full numerical solution indicate that: i. ii. The value of the residual stress does not depend on the rate at which the phasechange front zs (t) moves but rather on the shape of the temperature pro®le in the solid at each zs position; The shape of the temperature pro®le in the solid approaches a linear form when the value of the Stefan number, St, decreases (which a limit analysis of the wellknown Neumann solution of the Stefan melting problem will readily show [10]). Borrowing some of the concepts from the well-known heat balance integral (HBI) method [12], these observation s suggest that the temperature in the solid could be modeled by an approximating pro®le that evolves with the movement of zs. If well chosen, this approximating pro®le could be used to arrive at an analytical integration of Eq. (6) and, in turn, an explicit analytical expression for the residual stress ®eld in the part. A ®rst cut approach is to assume perfect thermal contact between the mold and the part, that is, the Biot number approaches in®nity, and employ the linear approximation T(z; t) = Ts – Tf z ‡ Tf zs (t) (15) Using Eq. (15) in Eqs. (6)±(8) does indeed lead to an analytical expression for the stress ®eld (see derivation in the appendix) ³ ´ E b ¢ b(Tf – Ts ) ¢ ln – 1 s(z) = 2(1 – v) z (16) As might be expected, however, there is a singularity at z = 0 (the surface), where, when the ®rst solid skin forms, there is an in®nite temperature gradient. Nevertheless, when compared with a full numerical solution of a problem characterized by a large Biot number (a large h), the approximate analytical and full numerical solutions for the residual stress are very close across the majority of the part thickness; see Figure 7. With reference to Figure 5, however, it is clear that the performance of the model in Eq. (16) will begin to deviate when smaller, more realistic, Biot numbers are used; in this case, the assumption of a ®xed surface temperature of Tf is not valid. The proposed approximate treatment can be remedied to account for the e ect of the Biot number by using the ideas in the virtual adjunct mold (VAM) method devised to account for ®nite heat transfer coe cients in the HBI modeling of steel solidi®cation [13, 14]. The idea is to add a virtual extension to the polymer domain with surface at z = – D ( D > 0) ®xed at temperature Tf. The thickness of the added domain will depend on the value of the Biot number (thin if the Biot number is large, thick if the Biot number is small). The VAM concept is illustrated schematically in Figure 8. With the VAM the approximating linear pro®le takes the form STRESS IN AN INJECTION MOLDED PART Figure 7. Comparison numerical solution and initial HBIM approximation (70% starch). Figure 8. The virtual adjunct concept. 533 534 X. ZHANG ET AL. T(z; t) = Ts – Tf [z ‡ D ] ‡ Tf zs (t) ‡ D 0 µ z µ zs (t) (17) When Eq. (17) is used in the residual stress model, Eqs. (6)±(8), an analytical treatment can be realized, resulting in an explicit expression for the residual stress distribution, an expression that does not have a singularity in the real domain s(z) = » µ ¶ ¼ E b‡ D z b(Tf – Ts ) ln – 2(1 – v) z‡ D z‡ D (18) where a curve-®tting exercise indicates that the virtual adjunct is a function of the Biot number Bi D b = 0:04 ‡ 1:37 Bi (19) Equations (18) and (19), referred to as the LHBI-VAM model, to signify the coupling of a linear HBI with a VAM, is the key result in this article. This model allows for the immediate calculation of the residual stress that will result from a given injection molding set-up. For completeness, a detailed derivation of Eq. (18) is given in the appendix. RESULTS Comparison Between Numerical Solution and Approximation Figure 9 compares LHBI±VAM predictions of Eqs. (18) and (19) with a full numerical solution across a wide range of Biot numbers. These results indicate a very high accuracy for the approximate LHBI±VAM solution. Comparison Between Approximation and Experimental Results A comparison of residual stresses from experimental measurements [6] on starchbased polymers (see Table 1) and the approximate LHBI±VAM solution is shown in Figure 10. Agreement between the experiment and approximate model is good. The most noticeable deviation occurs at the part surface where the LHBI±VAM predicts higher compressive stresses than those measured. It should be noted, however, that: i. The majority of the part thicknesses of the LHBI±VAM model are in very close agreement with the experimental measurements. ii. No attempt has been made to improve the ®t of the LHBI±VAM model; the data given in Table 1 [6] was obtained independently of the model. iii. The experimental techniques were made via the well-known layer removal technique [15]. This required a ®tting to determine the part curvature. It is reasonable to expect that this ®tting may be subject to the most error at the surface where large compressive stresses are formed. STRESS IN AN INJECTION MOLDED PART 535 Figure 9. Comparison of numerical and LHBI-VAM predictions (70% starch). CONCLUSIONS The ability to relate the residual stress in an injected molded part to processing conditions and material properties is an important step toward process optimization. Experimental measurements on the injection modeling of rectangular parts are su cient to characterize the levels of stress that might be encountered when fabricating a given polymer material under given processing conditions [6]. Although many e ects contribute to residual stresses during injection molding of polymers (e.g., packing pressure, viscoelastic relaxation, nonconstant material properties, degree of crystallinity), its formation may be adequately modeled using a one-dimensional thermoelastic treatment that assumes constant material properties. This model requires the coupled solution of a thermal solidi®cation problem and evaluation of the integral of stress through the part thickness. In a general setting, a numerical solution is needed, requiring a discretization in both space and time, to resolve the model fully. In this article it has been shown that, upon assuming (i) a linear temperature pro®le for the solid and (ii) a VAM to account for convective cooling, the solution of the residual stress model can be carried out analytically to arrive at an explicit relationship for the residual stress (see Eqs. (18) and (19)). This simple model allows for a direct assessment of the level of residual stress that will occur for a given polymer material under given injection molding conditions. Across a very wide range of conditions, the closed-form approximation, Eq. (18), provides residual stress predictions that are very close to those obtained with a full numerical solution. Predictions with the simple model also agree well with a range of experimental measurements made on starch-based biodegradable polymers. 536 X. ZHANG ET AL. Figure 10. Comparison of LHBI-VAM predictions with experimental measurements. The applicability of the proposed approach rests on assuming that the phase change can be modeled as a sharp front moving from the part surface to the part center. In a strict sense this should restrict the use of the approximation to crystalline or semicrystalline polymers, but since the predictions from the model are relatively STRESS IN AN INJECTION MOLDED PART 537 insensitive to the value of the Stefan number (see Figure 4) it is expected that the approximation could also be used with some con®dence to obtain residual stress pro®les for amorphous polymers. The method may not be accurate, however, for situations with large packing pressures. Recent research [16] has shown that any manipulation of the packing pressure can have an e ect on the residual stress pro®le. Current work is aimed at addressing this de®ciency. Taken as a whole the results in this article have shown that: i. The LHBI±VAM treatment provides an accurate solution of the one-dimensional thermal-elastic residual stress model. ii. The formation of residual stresses is adequately modeled by a thermal-elastic treatment alone. iii. The LHBI±VAM model provides an accurate description of how the residual stress in an injection molding process is a ected by process conditions and material properties. REFERENCES 1. A. I. Isayev, Injection and Compression Molding Fundamentals, Marcel Dekker, New York, 1987. 2. R. Y. Chang and S. Y. Chiou, A Uni®ed K-BKZ Model for Residual Stress Analysis of Injection Molded Three-Dimensional Thin Shapes, Polymer Engng. Sci., vol. 35, pp. 1733±1747, 1995. 3. H. H. Chiang, K. Himasekhar, N. Santhanam, and K. K. Wang, Integrated Simulation of Fluid Flow and Heat Transfer in Injection Molding for the Prediction of Shrinkage and Warpage, J. Engng. Mat. Tech., vol. 115, pp. 37±47, 1993. 4. A. I. Isayev and D. L. Crouthamel, Residual Stress Development in the Injection Molding of Polymers, Polymer-Plastic Tech. Engng., vol. 22, pp. 177±232, 1984. 5. B. Haworth, C. S. Hindle, G. J. Sandilands, and J. R. White, Assessment of Internal Stresses in Injection-Moulded Thermoplastics, Plastics Rubber Proc. Appl., vol. 2, pp. 59±71, 1982. 6. A. Sen and M. Bhattacharya, Residual Stresses, Density Gradient in Injection Molded Starch= Synthetic Polymer Blends, Polymer, vol. 41, pp. 9177±9190, 2000. 7. T. A. Osswald and G. Menges, Materials Science of Polymers for Engineers, Hanser, Munich, 1996. 8. L. D. Coxon and J. R. White, Residual Stresses and Aging in Injection Molded Polypropylene, Polymer Engng. Sci., vol. 20, pp. 230±236, 1980. 9. V. R. Voller, An Overview of Numerical Methods for Phase Change Problems, Adv. in Numer. Heat Transfer, vol. 1, pp. 341±375, 1996. 10. J. Crank, Free and Moving Boundar y Problems, Clarendon Press, Oxford, 1984. 11. R. F. Eduljee, J. W. Gillespie, Jr., and R. L. Mccullough, Residual Stress Development in Neat Poly(Etheretherketone), Polymer Engng. Sci., vol. 34, pp. 500±506, 1994. 12. T. R. Goodman, The Heat-Balance Integral and its Application to Problems Involving a Change of Phase, Trans. A.S.M.E., vol. 80, pp. 335±342, 1958. 13. V. R. Voller, Development and Application of a Heat Balance Integral Method for Analysis of Metallurgical Solidi®cation, Appl. Math. Modelling, vol. 13, pp. 3±11, 1989. 14. A. Garcia and M. Prates, Met Trans. B, vol. B9, pp. 449±457, 1978. 15. R. G. Treuting and W. T. Read, Jr., A Mechanical Determination of Biaxial Residual Stress in Sheet Materials, J. Appl. Phys., vol. 22, pp. 130±134, 1951. 16. R. P. Kambour, J. C. Caraher, R. C. Schnoor, M. R. Todt, H. P. Wang, and S. J. Willey, Tensile Stresses in the Edges of Injection Moldings: Roles of Packing Pressure, Machine Compliance, and Resin Compression, Polymer Engng. Sci., vol. 36, pp. 2863±2874, 1996. 538 X. ZHANG ET AL. APPENDIX: DERIVATION OF THE LHBI-VAM MODEL, EQ. (18) In – D µ z µ zs the approximating temperature pro®le is T(z; t) = Ts – Tf T f zs ‡ T s D z‡ zs ‡ D zs ‡ D and b(T – Ts ) = b Ts – Tf ¢ (z – zs ) zs ‡ D Substituting into Eq. (6) with some rearrangement and simple integration gives b Ts – Tf 2 zs ¢ ev (zs ) = – ¢ ¢z ‡ 2 zs ‡ D s Z zs ev dz 0 Taking the derivative dev 1 zs = 2A ¢ – A¢ dz s zs ‡ D (zs ‡ D ) 2 where the constant A = b(Tf – Ts )=2. Since the ¯ow strain is a function of space alone dev 1 z = 2A¢ – A¢ dz z‡ D (z ‡ D) 2 which has the general solution ev = A ¢ ln(z ‡ D ) – A ¢ D ‡C z‡ D Substitution into Eq. (7) gives etot = 2 A ‡ C ‡ A[ln(b ‡ D ) – 1] From which, through Eq. (8), the LHBI±VAM expression for the stress at ®nal cooling, Eq. (18) in the main text, results in » µ ¶ ¼ E b‡ D z s(z) = b(Tf – Ts ) ln – 2(1 – v) z‡ D z‡ D In the limit, D ! 0, the perfect thermal contact expression for the residual stress, Eq. (16), follows.