Capacitive Coupled Contactless Interconnect Design for 3D ICs

advertisement

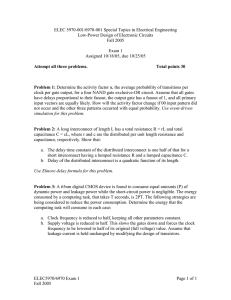

Capacitive Coupled Contactless Interconnect Design for 3D ICs Tony T. Kim and Myat Thu Linn Aung VIRTUS, School of Electrical and Electronic Engineering, Nanyang Technological University, Singapore Email: thkim@ntu.edu.sg Abstract Data Link (chip A) Abstract—Through-Silicon-Via (TSV) has been considered as a promising technology in 3D integration. However, it has several challenges such as thermal issues, mechanical stress, etc. Contactless interconnect techniques such as inductive coupling and capacitive coupling have been investigated as alternative solutions. In this paper, we present several capacitive coupled interconnect structures. Various challenges in each interconnect structure and design techniques are discussed. (a) (b) TxL Drv. TxL Drv. CC (c) Design of Capacitive Coupling Interconnect A. Conventional capacitive coupled interconnect Fig. 1(a) illustrates a conventional uni-directional CCI structure. The coupling capacitor (CC) formed by the parasitic capacitance between two top metals transfers the data transition at the driver output to the receiver side [5]. For better signal integrity, larger CC and smaller parasitic capacitance at the receiver node are desired. For bi-directional signaling, each side requires both a driver and a receiver that are controlled based upon the direction of signal transmission (Fig. 1(b)). With the same CC, smaller voltage is generated at the receiver side due to the additional parasitic capacitance coming from either the unselected receiver or the unselected transmitter [4]. To compensate this signal level degradation, larger 978-1-4673-9308-9/15/$31.00 ©2015 IEEE Rcv. RxR Drv. TxR Rcv. RxR ENL ENR RxL Rcv. TxL Drv. Keywords-high temperature; 3D ICs; capacitive coupled interconnect Introduction As CMOS technology scaling faces fundamental limitations, 3-dimensional (3D) integration has been considered as a promising solution to overcome the CMOS scaling limitation. 3D integration can provide various benefits such as short interconnect, high interconnect density, small form factor, and heterogeneous integration. Through-Silicon-Via (TSV) is one of the most effective ways for 3D integration. However, TSVs are subject to various issues such as mechanical stress, stringent placement requirement, low yield, and high cost [1]. Alternative interconnect structures utilizing inductive coupling [2, 3] and capacitive coupling [4-6] have been explored. These techniques do not require additional complex and precise processing steps. While the inductor coupling technique can communicate more than two stacked dies, it requires much large area due to the on-chip inductor, relatively complex circuitry for transmitting and receiving data, and higher power consumption. The capacitive coupling technique can overcome these issues except that it is only applicable to face-to-face die stacking. In this paper, several capacitive coupled interconnect (CCI) structures, their design challenges, and several circuit solutions are discussed [6-8]. Data Link (chip B) CC V clamp CD A RefH RefL RxL Rcv . & Rcvr. CD CC B TxR V clamp RefH RefL RxR Rcv . & Rcvr. Figure 1. Three different types of capacitive coupling based interconnection are presented. (a) uni-directional signaling; (b) bi-directional signaling; (c) proposed simultaneous bi-directional signaling [9]. Figure 2. Multi-level signaling principle of the proposed transceiver. [9] capacitance needs to be implemented, which increases the electrode size. B. Simultaneously bidirectional capacitive interconnect To improve the data rate per silicon area or channel, a simultaneously bidirectional capacitive coupled interconnect was proposed in [9]. Fig. 1(c) depicts the interconnect using three capacitors in series. The coupling capacitor (CC) is realized by the parasitic capacitance between two stacked dies while the driving capacitor (CD) in implemented in each die to transfer the data transition in each side to the other side through capacitive coupling. Four voltage levels can be formed at the floating receiver nodes (A and B) depending upon the data from both sides. The voltage levels associated with the transmitting data are illustrated in Fig. 2. When TxL is ‘1’, the voltage at the receiver node (A) will be formed at a higher level. Similarly, if TxL is ‘0’, the voltage at A will be at a lower level. Therefore, the receiver requires two reference levels (RefH and RefL) to sense the signal swings between ‘00’ and ‘01’ and between ‘10’ and ‘11’. The dead zone represents the range that - 121 - ISOCC 2015 Figure 3. (a) proposed CCI structure for testing and (b) its input and output waveform at 28Mbps for probing [9]. C. Capacitive interconnect structure for crosstalk cancellation High density interconnect is highly required in 3D ICs for better performance and communication parallelism. However, when multiple channels are placed closely, crosstalk plays a critical role in the signal integrity of CCIs. Various techniques for crosstalk mitigation have been investigated such as GND shielding and the butterfly differential array structure [7] at the cost of significant area overhead. To tackle this, we developed a hybrid CCIs array structure as shown in Fig. 4 [8]. In this array, both single-ended and differential common-centriod CCIs are interleaved together. Any crosstalk from differential CCIs to the surrounding CCIs is cancelled due to the complementary nature of the noise; whereas differential CCIs undergo common-mode crosstalk noise from surrounding single-ended CCIs. The common-mode crosstalk can easily be suppressed by designing receivers insensitive to the input common-mode level. Fig. 5 compares the proposed CCI array with the conventional one. Note that the proposed CCI array improves the eye-diagram significantly while the conventional shows no eye opening. Fig. 6 is the receiver used in the differential CCI. For the common-mode insensitivity, the receiver input nodes (RX and /RX) are self-biased at VDD/2 and the input signals (IN and /IN) are transferred to RX and /RX through bypass capacitors. The receiver detects short pulses occurring only when signal transitions happen at IN and /IN (Fig. 7). Consequently, the proposed CCI array enables high density interconnect without significant power and area overheads. Summary Capacitive coupled interconnect (CCI) can address various challenges in TSV-based interconnect with low cost and high reliability. Several CCI schemes such as simultaneously bidirectional CCI and a hybrid CCI array structure for crosstalk cancellation are discussed as interconnect solutions for 3D ICs. 978-1-4673-9308-9/15/$31.00 ©2015 IEEE Figure 4. Proposed hybrid array structure in 3 × 3 array configuration [8]. Voltage (V) cannot be used for signaling. This is occurring due to the parasitic capacitance at the receiver node, which limits the signal swing like the parasitic capacitance at the conventional capacitive coupled interconnect. The signal swing can be improved by reducing the parasitic capacitance or increasing CC. Fig. 3(a) describes the test structure fabricated for verification. The tramsmitting data through the data input (TxL) is recoverd at RxR and used as the transmitting data at TxR. The finally recovered data at the data output (RxL) shows the same data pattern as TxL. (a) (b) Figure 5. Eye-diagram comparison: (a) conventional array and (b) proposed arry (differential CCI output) [8]. Figure 6. Proposed self-biased fully differential receiver [8]. Figure 7. Input and output waveforms of the proposed receiver [8]. Acknowledgement The authors would like to acknowledge the funding support from NTU-A*STAR Silicon Technologies Centre of Excellence under the program grant No. 11235150003. References [1] [2] [3] [4] [5] [6] [7] [8] [9] - 122 - W. R. Davis, et al., DTC, vol. 22, pp. 498-510, 2005. M. Saen, et al., JSSC, vol. 45, pp. 856-862, 2010. N. Miura, et al., ISSCC, 2007, pp. 358-608. A. Fazzi, et al., JSSC, vol. 43, pp. 275-284, 2008. A. Fazzi, et al., JSSC, vol. 42, pp. 2270-2282, 2007. G. Qun, et al., ISSCC, 2007, pp. 448-614. D. Hopkins, et al., ISSCC, 2007, pp. 368-609. A. Myat Thu Linn, et al., ISCAS, 2013, pp. 966-969. A. Myat Thu Linn, et al., TCAS-II, vol. 61, pp. 706-710, 2014. ISOCC 2015