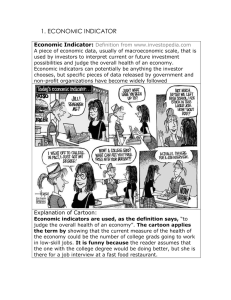

PositionLine |Position Indicators

advertisement