Arborist Industry Safe Work Practices

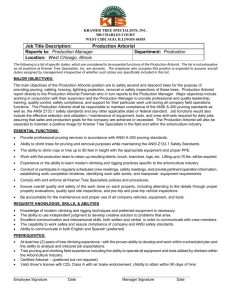

advertisement