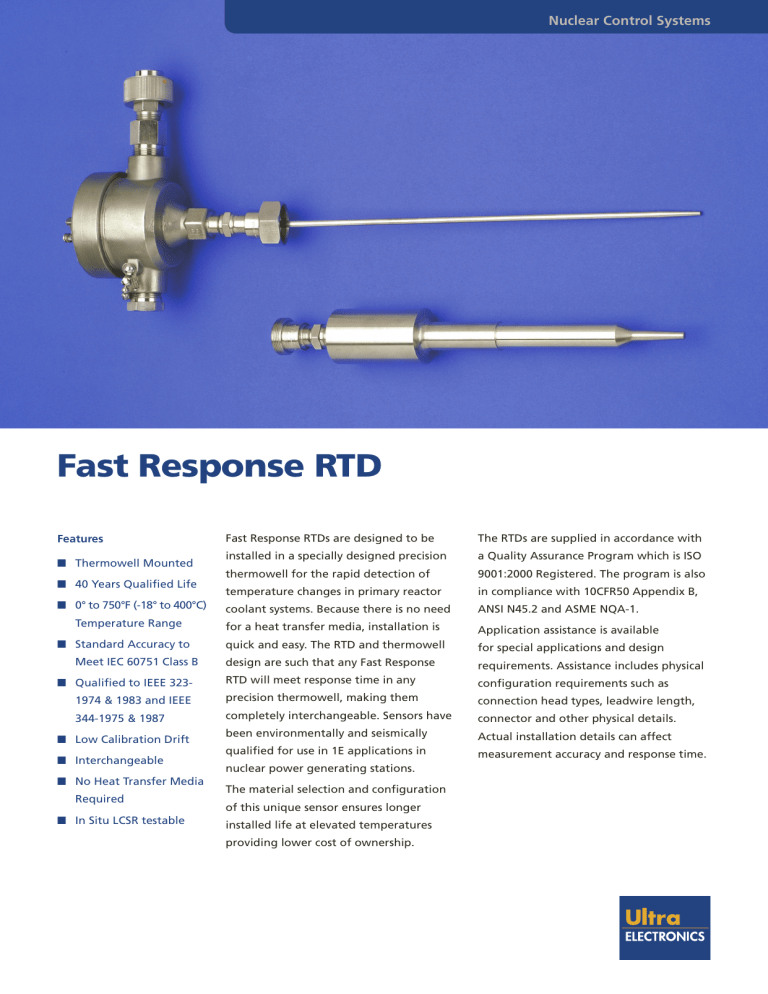

Fast Response RTD

advertisement

Nuclear Control Systems Fast Response RTD Fast Response RTDs are designed to be The RTDs are supplied in accordance with installed in a specially designed precision a Quality Assurance Program which is ISO thermowell for the rapid detection of 9001:2000 Registered. The program is also temperature changes in primary reactor in compliance with 10CFR50 Appendix B, coolant systems. Because there is no need ANSI N45.2 and ASME NQA-1. for a heat transfer media, installation is Application assistance is available quick and easy. The RTD and thermowell for special applications and design design are such that any Fast Response requirements. Assistance includes physical ■ Qualified to IEEE 323- RTD will meet response time in any configuration requirements such as 1974 & 1983 and IEEE precision thermowell, making them connection head types, leadwire length, 344-1975 & 1987 completely interchangeable. Sensors have connector and other physical details. been environmentally and seismically Actual installation details can affect qualified for use in 1E applications in measurement accuracy and response time. Features ■ Thermowell Mounted ■ 40 Years Qualified Life ■ 0° to 750°F (-18° to 400°C) Temperature Range ■ Standard Accuracy to Meet IEC 60751 Class B ■ Low Calibration Drift ■ Interchangeable ■ No Heat Transfer Media Required ■ In Situ LCSR testable nuclear power generating stations. The material selection and configuration of this unique sensor ensures longer installed life at elevated temperatures providing lower cost of ownership. Nuclear Control Systems Fast Response RTD Specifications Performance specifications sensor. Standard operating current is 1 to 4 Operating temperature range milliamps. 0°F to 750°F (-18°C to 400°C) Self Heating Accuracy/calibration In 20°C water flowing transverse to the Standard sensor accuracy follow normal sensor sheath at 3 feet per second, with a IEC 60751 Class B. Consult factory if Class sheath diameter of 0.25 inch, the RTD will A or other special accuracy requirements be capable of dissipating 10mw/°C are needed. Standard calibration points without causing an indicated temperature are 32°F, 212°F and 554°F (0°C, 100°C and rise of more than 0.2°C. 290°C). (Other calibration points can be Environmental/seismic qualification performed upon customer request.) Sensor RTDs are qualified to IEEE-323 1974 & specific calculated calibration tables of 1983, and IEEE-344 1975 & 1987 and Resistance vs. Temperature can be provided NUREG 0588 for a design life of 40 years. from 0°F to 750°F in 1°F (or 1°C) increments. The RTD assembly will withstand up to Drift/stability 300 Megarads T.I.D. and LOCA conditions. Sensor drift is less than 1°F over 40 years. Seismic capability of the RTD is 20g Response Time maximum acceleration in the horizontal The response time for each sensor is 4 and vertical plane from 1 to 33 Hz. seconds or less in a clean, dry precision (Applicable qualification/test reports are thermowell as verified by a plunge test in available upon request). accordance with ASTM E644. General specifications Insulation resistance Storage At room temperature and dry external Storage of the RTD should be in accordance surfaces, the insulation resistance between with ANSI N45.2 Level B. any terminal and the sensor case will exceed Shipping weight 100 Megohms with 100 VDC applied. Approximately 4 pounds with a single port Operating current connection head. A continuous current of no greater than Electrical connectors 20 milliamp (RMS) will not damage the Available as an option. Ultra Electronics NUCLEAR SENSORS & PROCESS INSTRUMENTATION 707 Jeffrey Way PO Box 300 Round Rock TX 78680-0300, USA Tel: +1 512 434 2800 Fax: +1 512 434 2951 e-mail: nuclear@ultra-nspi.com www.ultra-nspi.com www.ultra-electronics.com Ultra Electronics reserves the right to vary these specifications without notice. © Ultra Electronics Limited 2011. Printed in England REF: FRRTD001