Kilowatt Three-phase Rotary Transformer Design for a Permanent

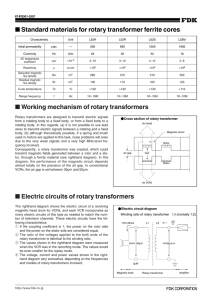

advertisement

Självständigt arbete på avancerad nivå

Independent degree project - second cycle

Masterexamen med huvudområdet elektronik

Master of Science (120 credits) with a major in Electronics

Kilowatt Three-phase Rotary Transformer Design for

Permanent Magnet DC Motor with On-rotor Drive System

Ye Xu

MID SWEDEN UNIVERSITY

Department of Electronics Design (EKS)

Examiner: Göran Thungström, goran.thungstrom@miun.se

Supervisor: Peng Cheng, peng.cheng@miun.se

Co-supervisor: Bengt Oelmann, bengt.oelmann@miun.se

Author: Ye Xu, yexu1000@student.miun.se

Degree programme: Master of Science, 120 credits

Main field of study: Electronics

Semester, year: VT, 2016

Abstract

The aim of this thesis is to design a kilowatt three-phase step-down rotary transformer for

a permanent magnet DC motor. The permanent magnet DC motor has an on-rotor drive

system, and therefore requiring a power supply that can transfer power to its drive unit

without mechanical contact. The rotary transformer has a detached magnetic coupling

structure that qualifies it as a potential method for the wireless power transfer.

This thesis studies the rotary transformer as a static device, focusing on its core loss.

By using a transient finite element analysis of COMSOL Multiphysics and an iron loss

prediction model, the rotary transformer was optimized in terms of efficiency and power

density for the on-rotor drive system through proper material selection and geometry exploration. After this, a mechanical design, which based on a literature review of the

influences of manufacturing processes on electrical steels, was proposed for realizing the

core fabrication and the rotary transformer assembly.

The results show that the rotary transformer can step down 400 V/50 Hz three-phase

voltage to 13.15 V in a Delta-wye connection and output 1.17 kW power over an air-gap

of 0.3 mm with 95.94% overall efficiency. The proposed mechanical design enables the

transformer to minimize the core loss and the manufacturing cost. Without using resonant inductive coupling, this transformer design simplifies the power supply for the motor,

thereby decreasing the motor manufacturing and maintenance cost.

Keywords: contactless energy transfer, transformer power loss, iron loss, iron loss model,

rotary transformer, three-phase transformer, finite element method, COMSOL Multiphysics, electrical steel, electrical steel manufacturing process

i

Acknowledgement

I would like to, firstly, express my deep gratitude to Dr. Peng Cheng, my thesis supervisor,

for his patient guidance, enthusiastic encouragement, and useful critiques of this thesis

work. I also thank gratefully my assistant supervisor, Prof. Bengt Oelmann for helpful

suggestions during the thesis development.

My special thanks are extended to Nazar ul Islam, Stefan Haller, Dr. Kent Bertilsson,

Dr. Sebastian Bader and Mattias Kramer for their support, time in patiently listening to

me and helping me work out my problems during this Master by Research. I am also

indebted to Dr. Najeem Lawal for helping me out of some troubles about my student visa.

(By the way, I am not Cheng 2.0...)

Additionally, I would like to take the opportunity to thank my Chinese friends in

Sundsvall, Xinyu Ma, Hao Shi, Congrui Liu (cute baby deer), Hanxue Xu, Mengxuan Li,

Dingding Sun, Jiayi Wang, Pengxiang Cheng, Tian Xie and Ziheng He, for their delicious

Chinese food, help or bringing so much fun in my life.

Furthermore, special thanks go to Florian Gebben, Onyedika Sunday Okonkwo, and

Till Dreier. You make me not feel alone because I can have some classmates in this

programme of Master by Research.

I also owe my sincere gratitude to my two best friends, Yunxiang Jia and Xiaotian Li,

who gave me their endless help, care, understanding and forgiving throughout my years

of study and live in Sweden. Most importantly, my deepest gratitude goes to a very nice

girl, Siwen An, for providing me with unfailing support and continuous encouragement.

Finally, I should like to, affectionately, express my gratitude to my parents who have

always been helping me out of difficulties and supporting without any complaint through

these years and, even, in future.

Ye Xu

Sundsvall, Sweden

May 2016

ii

Contents

Abstract

i

Acknowledgment

ii

1

.

.

.

.

1

1

3

4

5

.

.

.

.

.

.

.

.

.

.

6

6

8

10

10

11

12

12

13

15

17

2

3

4

Introduction

1.1 Background of the Thesis Work .

1.2 Thesis Objectives and Scope . . .

1.3 Thesis Overview and Methodology

1.4 Thesis Outline . . . . . . . . . . .

Background

2.1 Theory of Transformer . . . .

2.2 Transformer Types . . . . . .

2.3 Power Loss in Transformer . .

2.3.1 Winding Loss . . . . .

2.3.2 Iron Loss . . . . . . .

2.4 Transformer Materials . . . .

2.4.1 Winding Conductor . .

2.4.2 Electrical Steel . . . .

2.5 Review of Rotary Transformer

2.6 Summary . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Three-phase Rotary Transformer Design

3.1 Three-phase Rotary Transformer Structure

3.2 Air-gap . . . . . . . . . . . . . . . . . .

3.3 Configuration of Transformer Connection

3.4 Power loss Analysis . . . . . . . . . . . .

3.5 Core Construction and Material Selection

3.6 Summary . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

18

19

20

21

21

23

24

Iron Loss Model Development for Three-phase Rotary Transformer

4.1 Iron Loss Model . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.1 Iron Loss Prediction Errors . . . . . . . . . . . . . . . . .

4.1.2 Iron Loss Determination . . . . . . . . . . . . . . . . . .

4.1.3 Iron Loss Model Development Step . . . . . . . . . . . .

4.2 Iron Loss Model of M235-35A . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

25

25

26

26

26

27

iii

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Contents

5

6

7

8

Two-dimensional Transient Finite Element Analysis

5.1 Model Definition . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 Geometry Drawing and Material Assignment . . . . . .

5.1.2 Analytic Function Definition for Using Iron Loss Model

5.1.3 Slitted O-ring Lamination Modelling . . . . . . . . . .

5.1.4 Meshing of FEM Model . . . . . . . . . . . . . . . . .

5.2 Transient Simulation . . . . . . . . . . . . . . . . . . . . . . .

5.3 Result . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

30

30

31

33

34

34

35

36

Review of Influences of Manufacturing Processes on Electrical Steels

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Mother Coil and Slitting Process . . . . . . . . . . . . . . . . . . .

6.3 Losses Due to Cutting Techniques . . . . . . . . . . . . . . . . . .

6.3.1 Wire Electrical Discharge Machining . . . . . . . . . . . .

6.3.2 Milling . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.3 Summary of Different Cutting Methods . . . . . . . . . . .

6.4 Losses Due to Stacking . . . . . . . . . . . . . . . . . . . . . . . .

6.4.1 Sticking . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Annealing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 Losses Due to Frame Assembly . . . . . . . . . . . . . . . . . . .

6.7 Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

41

41

42

42

43

44

45

46

46

47

49

49

Transformer Mechanical Design

7.1 Mechanical Design Overview . . . . . .

7.2 Winding and Core Design . . . . . . . .

7.2.1 Rotor-radial Core . . . . . . . .

7.2.2 Rotor-axial Core . . . . . . . .

7.2.3 Secondary Winding . . . . . . .

7.2.4 Primary Wining and Stator Core

7.3 Transformer Assembly . . . . . . . . .

7.4 Summary of Mechanical Design . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

51

51

53

53

55

55

57

57

61

Conclusions and Future Work

8.1 Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Recommendations for Further Work . . . . . . . . . . . . . . . . . . . .

64

64

65

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Appendix

A

HB-curve and specific iron loss of M235-35A given by ThyssenKrupp Steel

B

Epstein Frame Measurement . . . . . . . . . . . . . . . . . . . . . . . .

C

SPICE Model Coupled to the Magnetic Field Model of the Transformer .

D

Geometry of the Three-phase Rotary Transformer Drawn in COMSOL

Multiphysics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E

Equations Used in COMSOL Multiphysics for Modelling the Three-phase

Rotary Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F

Dimension of O-ring laminations in the rotor-radial core . . . . . . . . .

G

Dimension of O-ring laminations in the stator-radial core . . . . . . . . .

H

Magnet wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

68

68

69

71

72

73

74

75

76

Contents

I

Frame and Terminal Box Assembly . . . . . . . . . . . . . . . . . . . .

References

77

77

v

Chapter 1

Introduction

This chapter describes the background, the objectives, and the scope of this Master by

Research. Furthermore, the overview and outline of this thesis are presented.

1.1

Background of the Thesis Work

The permanent magnet DC (PMDC) motor with on-rotor drive system is still an ongoing

project, which designs a new kind of PMDC motor that has a higher efficiency but a lower

cost compared with industrial motors in the same power rating. However, for the usability

of industrial applications, this motor must have a series of standard interfaces, including

control, communication, power connection and even mechanical installation. This thesis

work contributes a power supply by using the standard three-phase power (400 V/50 Hz)

to this new PMDC motor.

stator

rotor

Control outputs

On-rotor drive

controller

Standard I/O Industry control

interface

Motor

drive unit

Voltage/Current

settings

Three-phase Line-frequency

utility power step-down rotary

transformer

primary coil on Induction

coupling

stator

Line-frequency

step-down rotary

Active MOSFET

Multi-phase

transformer

rectifier with

secondary coil Low-voltage optional power- Low-voltage DC/DC stephigh-current factor correction high-current down regulator

on rotor

three-phase

DC line

Figure 1.1: Functional modules of on-rotor drive system

Permanent magnet brushed DC motor existed a long time ago and it had a lot of troubles with the mechanical commutation brushes and electromagnetic interference (EMI)

generated by brush arcing [1]. Hence, it was never efficient compared with modern induction motors. However, the new PMDC motor has an on-rotor drive system shown in

Figure 1.1, which includes several function modules to directly deliver the utility power

from the stator and control the voltage and current of the motor drive unit to run the motor

optimally at different speed and torque. This system eliminates the need of conventional

brushes and drives the motor with much lower voltage (less than 20 V) and higher current

1

Chapter 1. Introduction

(up to dozens of kA) using off-the-shelf multi-phase DC/DC step-down power regulators

like the ones used in all the PCs for CPU power supply.

To sum up, the new PMDC motor requires a power supply that has a contact-free operation to transfer electrical power to its drive unit in the rotor without using slip rings

or brushes. A rotary transformer, a transformer with an axial symmetry and an air-gap

between the primary side and the secondary side, has a detached magnetic coupling structure that qualifies it as a potential method for avoiding the wear of the rotating parts, and

therefore achieving a contactless energy transfer (CET) system.

CET offers significant advantages over conventional methods of electrical power transfer, such as contact rails or cable handling systems. Designing a power supply with CET

can lower the system maintenance cost and higher the system availability. [2] presents

a general classification of CET systems shown in Figure 1.2. The medium for power

transfer in CET systems could be used acoustic waves, electromagnetic waves including

light, as well as electric (capacitive) or magnetic (inductive) field. Typical applications

of using acoustic waves and lights are powering wireless sensors combined with energy

harvesting techniques [3, 4]. Capacitive CPT using electric coupling between conducting

plates separated by a dielectric. Electric fields exhibit better directionality than magnetic

fields, resulting in reduced EMI shielding requirements [2,5,6]. For most industrial applications, by means of inductive power transfer (IPT) techniques, achieving a CET system

based on unconventional transformers, such as rotary transformers [7–10], linear transformers [11, 12] and sliding transformers [13–15].

Contactless

Energy

Transfer

Systems

Acoustic

Capacitive

Coupling

Inductive

Coupling

with Magnetic

Cores

Light

with Magnetic

Core on

Secondary Side

without

Magnetic

Cores

Figure 1.2: Classification of CET systems [2]

Currently, IPT is the most popular research topic and widely investigated and used in

many applications, such as active implantable medical devices (AIMDs) [16,17], portable

electronics 1) , and electric vehicles (EVs) [18–20]. To reduce losses and maximize power

transfer capability, designers add series or parallel capacitors to IPT circuits to compensate the inductance of coils to achieve resonant frequency IPT systems. To reduce the

size of transformers and other passive components in an IPT system, the mains AC power

(50 Hz or 60 Hz) is switched at a higher frequency by using switching mode power supplies (SMPS).

In recent decades, soft-switching technique and zero-voltage switching (ZVS) bridge

continue to mature, and adopting them in a SMPS can reduce the switching losses and

1)

Qi Standard, https://www.wirelesspowerconsortium.com/

2

Chapter 1. Introduction

Rator

Stator

Mains power

Primary

AC/DC

converter

Primary

resonant

circuit

Secondary

resonant

circuit

Coupling

transformer

Wireless

commutation

Primary

control unit

Secondary

AC/DC

converter

Load

Secondary

pick-up unit

(a)

Power flow

Rator

Stator

Control/Commutation

Mains power

Coupling

transformer

Secondary

AC/DC

converter

Load

(b)

Figure 1.3: Comparison between (a) inductive wireless power transformer and (b) line frequency wireless

power transfer

even EMI. Hence, using an SMPS with soft-switching technique and ZVS bridge enable

an IPT system to have a high power density with low loss and EMI, but complicating

the IPT system (see Figure 1.3a), which results in increasing troubleshooting time and

maintenance cost. Furthermore, like SMPS with loop compensation, a pick-up control

unit is added to the receive circuit (secondary circuit) to send feedback to the primary

control unit by a wireless commutation, which ensures the stability of the IPT system and

can transfer and use the power optimally [2,21]. However, adding the pick-up control unit

increases the complexity of the IPT system.

Transformer is the key unit in many industrial processes, and its reliability is the crucial factor to ensure uninterrupted power supply to motors in a wide variety of applications. This thesis work designs a simple and stable wireless power supply, similar to

a linear power supply shown in Figure 1.3b, for the new PMDC motor. Without using

the resonant and high switching frequency, this design results in a low power density and

bulky transformer. However, it can focus on the study and investigation of the transformer

core material and structure, which still is a challenge for the CET study.

1.2

Thesis Objectives and Scope

The main objective of this thesis work is to design a line frequency wireless power supply

system, which achieves that a rotary transformer has a simple step-down power process

and a detached magnetic coupling structure to transfer a three-phase electric power to the

rotor drive unit of the PMDC motor without using brushes or slip rings.

The rotary transformer can have an output power up to 1.1 kW with the efficiency of

over 90%, which steps down the mains three-phase power of 400 V/50 Hz to a low-voltage

and high-current power with up to 20 V. The transformer design optimization is required

to minimize the transformer volume to ensure that this rotary transformer can fit in an IEC

200 motor frame or a smaller standard size frame. Afterwards, a mechanical design for

realizing the rotary transformer should be proposed, which presents the manufacturable

3

Chapter 1. Introduction

transformer winding and core as well as necessary mechanical components for assembly

and cooling.

In the aspect of the transformer material selection and transformer power loss, this

thesis focuses on the study of electrical steel (Si-Fe steel) and iron loss.

In the aspect of the iron loss model study and the transformer finite element analysis,

this design ignores the influences of manufacturing processes on electrical steels, and only

uses the data-sheet to develop an iron loss model.

A complete power supply should consist of a transformer, a bridge rectifier, and filter

capacitors or DC/DC regulators, but this thesis only studies the transformer part.

Thermal analysis and cooling solution are essential to the transformer design, but,

in the finite element analysis, the factor of temperatures are not taken into account, and

all the material properties are, hence, modelled as temperature invariant. Moreover, the

mechanical design does not provide a cooling solution by means of a comprehensive and

rigorous study.

The mechanical design and assembly of this thesis focuses on the rotary transformer,

rather than the entire machine including the PMDC motor.

1.3

Thesis Overview and Methodology

Designing a rotary transformer is a nonlinear, multiphysics and multivariable problem,

of which complexity requires a finite element analysis software to perform a large number of studies for the design and optimization. Moreover, many conventional methods

of traditional transformer design cannot efficiently handle the very complex problem or

accurately evaluate the rotary transformer performance. Therefore, this thesis work uses

COMSOL Multiphysics to design the rotary transformer but does not give up using conventional methods if they are suitable for the performance analysis and optimization, such

as the determination of transformer parameters including the efficiency, power factor and

voltage regulation.

A complete study of transformer design should include two subsystems, magnetic

subsystem and electrical circuit subsystem. The magnetic subsystem study involves the

magnetic field of the transformer and the transformer core construction and material. The

electrical circuit subsystem is coupled to the magnetic subsystem, providing external voltage/current sources, loads and even the configuration of the winding connection for a

poly-phase transformer. This thesis work uses the Magnetic Field interface and Electrical

Circuit interface of COMSOL Multiphysics to finish the transformer geometry drawing

and the material selection and assignment, model the transformer, extract the relative data

from the simulation and present the transformer parameters.

Because of the non-linear characteristics of transformer core materials, using an iron

loss model is essential to the transformer design. The iron loss model embedded into

the finite element analysis behaves the magnetic hysteresis mathematically or empirically,

which can predict the transformer core loss and help designers to optimize the transformer

in the terms of power density and efficiency.

However, even if an iron loss model can predict the core loss accurately, its accuracy

is drastically reduced compared with the actual loss of the finally assembled transformer

because various manufacturing processes degrade the magnetic properties of the trans-

4

Chapter 1. Introduction

former core. Hence, this thesis presents a literature review and studies the iron loss in the

view of electrical steel manufacturing process. Furthermore, through the literature review,

suitable methods and processes, which can minimize the core loss and manufacturing cost

for producing the rotary transformer, are found, and they are presented in the transformer

mechanical design proposal for the rotary transformer prototype.

1.4

Thesis Outline

This thesis is organized in eight chapters with the following content:

• Chapter 1, the current chapter, briefs the introduction about the background and

scope of the thesis work. The overview and outline of the thesis are also presented

in this chapter.

• Chapter 2 gives a general introduction of transformers about the principle, various

types, power loss and materials. A short review of rotary transformers is presented

as well.

• Chapter 3 presents the three-phase rotary transformer structure, power loss and

core material selection.

• Chapter 4 introduces iron loss models and develops an iron loss model for predicting the core loss of the three-phase rotary transformer.

• Chapter 5 implements a two-dimensional transits finite element analysis on the

power loss of the three-phase rotary transformer and presents a series of performance parameters of this rotary transformer.

• Chapter 6 is a literature study of influences of the manufacturing process on the

magnetic properties and iron losses in electrical steels. The manufacturing processes that are suitable for the rotary transformer prototype are presented in more

detail in this chapter.

• Chapter 7 proposes a mechanical design and assembly for realizing the three-phase

rotary transformer.

• Chapter 8 presents the main summary and conclusion about this thesis work and

also suggests the possible future works on the three-phase rotary transformer design.

5

Chapter 2

Background

In 1830s-1880s, transformer was invented, developed and used in the real world, and it

creates a milestone in the history of electrical engineering [22]. Transformers have been

around in many electronic and electrical applications for quite a while, but fundamentals

of them are still being investigated. A transformer, a static electrical device, transfers

electrical signals or energy between two circuit networks by means of electromagnetic

induction. It can have a single winding, or two or more coupled windings with or without

a magnetic core for introducing mutual coupling between electric circuits. Magnetic flux

couples the primary and secondary windings, so two circuit networks that locate in primary and secondary separately are not connected to each other. A transformer can modify

levels of voltage and current, but it does not modify the frequency or, ideally, the amount

of power being transferred from one winding to another.

2.1

Theory of Transformer

Principle The principle of a transformer depends on Faraday’s law of electromagnetic

induction. As shown in Figure 2.1, a varying current Ip in the primary winding Np creates

a varying magnetic flux φm in the core by the applied voltage Vp , and a varying magnetic

field impinging on the secondary winding Ns . The magnetic field induces an electromotive force (EMF) E2 in the secondary winding.

Figure 2.1: Ideal transformer

The EMF of E1 is

E1 = Np

6

dφp

dt

(2.1)

Chapter 2. Background

where φp is the varying magnetic flux produced by Vp , and φp = φm cos(2πf t).

Turns ratio A transformer can achieve the difference in voltage between the primary

and the secondary circuits by changing the turns ratio between the primary and secondary

windings. The voltage ratio between primary and secondary windings is directly proportional to the turns ratio, which is expressed by

nTR =

Vp

Np

=

Ns

Vs

(2.2)

where Np , Ns , Vp and Vs are coil turns and voltages of primary and secondary windings.

The turns ratio dictates the operation of the transformer and the corresponding voltage

available on the secondary winding. The apparent load of primary Zlp is dependent on the

turns ratio, which is expressed by

Zlp =

Vp

Vs

= n2TR = n2TR Zls

Ip

Is

(2.3)

where Zls is the apparent load of the secondary circuit.

Efficiency An ideal transformer has a coupling coefficient of 1.0 and no internal losses;

the powers in the secondary and primary windings are exactly equal. In real transformers,

however, because of losses the secondary power is less than the primary power. The

efficiency of a transformer is the ratio of the output power to the input power.

η(%) =

Pout

100%

Pin

(2.4)

where Pout and Pin are the real output and the input powers, which are expressed by

Pout = Re{Vs Is }

Pin = Re{Vp Ip }

(2.5)

where Vp , Ip , Vs and Is are voltages and currents of the primary and secondary windings.

It should be note that the active power is used for the power efficiency calculation rather

than the item of apparent power or reactive power. A real transformer can not achieve an

efficiency of 100%, which leads designers to analyse the losses and influencing factors.

Power Factor Power factor is the relationship between active power and apparent power,

which is expressed by Equation 2.6.

cos ϕPF =

P

S

(2.6)

where P is the active power in W and S is the apparent power in VA, which are expressed

by Equation 2.7 and 2.8, respectively. In case of transformer, the active power is the real

power transmitted from the transformer to load, and the apparent power is the basis for

the transformer power rating.

P = IV = I 2 R [W]

(2.7)

7

Chapter 2. Background

S = Irms Vrms [VA]

(2.8)

Voltage Regulation The voltage regulation of a transformer is defined as the change in

secondary terminal voltage when the transformer loading is at the full-load applied while

the primary supply voltage is kept in a constant. The voltage regulation determines the

voltage drop that occurs in the transformer as the load voltage becomes too low as a result

of the transformers loading being too high which therefore affects its performance and

efficiency.

The voltage regulation, expressed in Equation 2.9, is the percentage of voltage difference between no load and full load voltages with respect to the full load voltage.

VR =

2.2

Vno-load − Vfull-load

100%

Vno-load

(2.9)

Transformer Types

Depending on purpose, use and construction, transformers can be categorized in different

ways. Generally, types of transformer are:

• Power/distribution/instrument transformer (Power rating and purpose)

– Power transformer is generally used in transmission networks of higher voltages (up to 36 kV) for step-up and step-down applications, and it is generally

rated above 2.5 MVA. It transfers electric energy in any part of the circuit

between the generator and the distribution primary circuits [23].

– Distribution transformer is used in lower voltage (e.g., 11 kV, 6.6 kV, 3.3

kV, 440 V, 220 V and 110 V) distribution networks as a means to end user

connectivity, and it is generally rated less than 200 MVA.

– Instrument transformer is used for instruments or measuring high voltage

or high current. It isolates the secondary control or meter circuitry from the

high voltage or current circuit that is connected to its primary winding.

– Step-up/down transformer is used for stepping up or down the voltage level

of power in power transmission or distribution networks.

• Single/poly-phase transformer (Electrical structure)

– Single-phase transformer is typically used for single-phase power transmission or distribution. It has only one primary winding and one or more than

one secondary windings.

– Poly-phase transformer is constructed by multiple single-phase transformers. A poly-phase transformer can have a two-phase, three-phase, six-phase

or even 24-phase that is used for DC rectification [24].

The most common poly-phase transformer is the three-phase transformer used for

electrical power generation, transmission, distribution and many industrial applications. A three-phase power system is advantageous over a single-phase power system, which requires a lesser amount of conductors for transferring the same amount

of energy as compared to the single-phase power [25]. The primary and secondary

8

Chapter 2. Background

windings of a three-phase transformer can be connected in different configuration

(e.g. Delta, star or interconnected star) to meet practical requirements [26].

• Isolation/auto transformer (Electrical structure)

– Isolation transformer: There is no direct electrical connection between two

windings. They are independently isolated and insulated from each other but

are coupled by mutual induction to transfer power or signals. An isolation

transformer can be a two-winding transformer or three-winding transformer.

– Auto transformer has the usual magnetic core but only one single winding;

the primary and secondary circuit are electrically and magnetically linking together by the transformer [27]. Therefore, it is an economy and high efficiency

transformer used in voltage step-up/down applications; however, the primary

and secondary windings do not have an isolation coupling of a conventional

double-wound transformer [28].

• Ordinary/rotary transformer (Mechanical structure)

– Ordinary transformer (or static transformer) is the general transformer widely

used in the world. The primary and secondary winding are using a common

core to achieve power and signals transmission and electrical isolations.

– Rotary Transformer has the particularity of an air-gap to enable the rotation

between the primary and the secondary. Comparing an ordinary transformer,

the primary and secondary windings of a rotary transformer have separate

cores to transfer power and signals over a physical distance, which can replace

slip rings or brushes across the rotary interface [7].

• Shell/core structure transformer (Magnetic circuit structure)

– Shell transformer: The windings of a shell type transformer are completely

surrounded by transformer core.

– Core transformer: The coils are wrapped around the core.

As shown in Figure 2.2, three-phase cores are constructed in three-, four- or

five-leg construction [26].

Figure 2.2: Three-phase core construction

The three-leg type three-phase transformer is the most common method of

three-phase transformer construction allowing the three phases to be magnetically linked. Flux of each leg uses the other two legs for its return path.

However, compared with the four-leg and five-leg type, three-leg core does

not provide a low reluctance path for flux, which causes more core losses.

9

Chapter 2. Background

• liquid-immersed/dry-type transformer (Cooling solution)

– Liquid-immersed transformer: It is an insulating oil filled or synthetic insulating liquid filled transformer. Its magnetic circuit and windings are immersed in the liquid. Those insulating liquids can help cool the transformer.

Some high-power rating transformers may have external active or passive

cooling units such as cooling fans, pumps and oil-to-water heat exchangers

to improve the heat emission efficiency [29].

– Dry-type transformer: Its cooling system is implemented with natural air

circulation. A dry-type transformer has a mechanical enclosure with a low

ingress protection (IP) rating with comparing a liquid-immersed transformer

[30].

The enclosure of both types of transformers is made of high thermal conductivity

metals such as aluminium alloy. Furthermore, the outer surface of an enclosure has

many fins (heat sinks) that can increase the area of heat dissipation.

2.3

2.3.1

Power Loss in Transformer

Winding Loss

Winding loss is resistive loss or copper loss, which is created by an electrical current in

the winding. Equation 2.10 presents the relation between the copper loss and current.

Pcu = I 2 R

(2.10)

The total copper loss of the primary or secondary in a poly-phase transformer is the sum

of losses of all phase windings, which is expressed by Equation 2.11.

Pcu-total =

N

X

In2 (Rcoiln + Rtern )

(2.11)

n=1

where n is the index for every phase, N the total amount of phases, Rcoiln and Rtern the

resistance of the nth phase winding and its terminals, receptively, and In the RMS current

in the nth phase winding. Since the both primary and secondary currents depend upon the

load of a transformer, copper loss in the transformer vary with the load.

In Equation 2.11, the resistance is dependent on the material and geometry of the

conductor, and it is

lρ

(2.12)

R=

A

where l is the conductor length, ρ is the conductor resistivity, and A is the cross-sectional

area of the conductor.

Furthermore, in AC power system, depending on the conductor cross-sectional area

and frequency, the skin effect and proximity effect have to be taken into account. When

an AC flows through an electrical conductor, the outer surface of that conductor carries

more current as compared to its center, which results in higher resistance to AC and is

called skin effect. Proximity effect is that the alternating flux in a conductor is caused by

10

Chapter 2. Background

the current of the other nearby conductor. The description of these effects’ calculations

can be found in [31].

2.3.2

Iron Loss

The iron losses are also referred as core losses. They are created by the varying magnetic

field in the iron parts of the machine. The two basic components of the iron losses are

the hysteresis and the eddy current losses. Both of these components result in the same

physical phenomenon which is Joule heating.

Hysteresis Loss Hysteresis loss is a part of loss of a transformer, which depends upon

the following factors [32]:

• The hysteresis loss is directly proportional to the area under the B-H curve i.e area

of the hysteresis loop.

• It is directly proportional to magnetization frequency.

• It is directly proportional to volume of the material.

Hysteresis losses originate from the molecular magnetic domains in core laminations,

resisting being magnetized and demagnetized by the alternating magnetic field [33]. Because poles of magnetic field in the core of a transformer is alternately shifted by the

magnetizing of alternating current. Each magnetizing cycle two poles of the core is magnetized to their opposite poles, i.e. the direction of magnetic field is changed. The process of magnetizing needs power to change the two poles, but the power to finish this

magnetizing comes from the input power and is not transferred to the secondary winding.

Additionally, this magnetizing causes power losses that are dissipated as heat [34]; if the

heat is transferred to windings, it will increase the electrical resistance and lead to more

ohmic losses.

In one cycle of magnetizing, the hysteresis loss (Ph in W) is expressed by Steinmetz

Formula [35, 36]:

Ph = Kh f V (Bmax )n

(2.13)

where

•

•

•

•

•

Kh – It is the constant dependent on the characteristics of core.

f – the frequency of a varying magnetic field (Hz)

Bmax – the maximum flux density of the magnetic field (T)

n – the Steinmetz index, it depends on the structure of a transformer core.

V – the volume of magnetic material (m3 )

Eddy current Loss The eddy current is applied to an electric current which circulates

within a mass of conductor material, when the material is situated in a varying magnetic

field. In a transformer, according to Faraday’s Law, it is caused by a changing magnetic

flux that passes through the transformer core.

Eddy current loss comes from two phenomenons. First, a transformer core is a kind of

electrical conductor, and a current will be induced by a changing magnetic flux in the core;

The eddy current can result the heating because the core has an ohmic resistance. Second,

eddy current essentially is a kind of electric currents, and it can generate a magnetic field

11

Chapter 2. Background

that has an opposite direction force to against the power of the magnetic field produced by

the primary. To reduce these losses, higher resistivity core material and thinner lamination

of transformer core are used.

The eddy current loss is expressed by

Pe = Ke f 2 (Bmax )2 (τl )2 V

(2.14)

where

•

•

•

•

•

2.4

2.4.1

Ke – It is the eddy current coefficient dependent on magnetic materials.

f – the frequency of a varying magnetic field (Hz)

Bmax – the maximum flux density of the magnetic field (T)

τl – the thickness of laminations (m)

V – the volume of a transformer core (m3 )

Transformer Materials

Winding Conductor

Windings of a transformer are constructed by magnet wires. Magnet wire or enamelled

wire is a copper or aluminium conductor has a thin insulation layer.

Insulation The insulation layer for a magnet wire that has different sizes, temperature

ratings and applications. TEMCo Industrial Power Supply 1) lists some common insulation types and their specifications.

Figure 2.3: Insulation layer types of magnetic wire

Conductor Material The windings consist of the current-carrying conductors wound

around the sections of the core, and these must be properly insulated, supported and

cooled to withstand operational and test conditions. Copper and aluminium are the primary materials used as conductors in transformer windings. Because the electrical conductive of aluminium is lower than that of copper, a larger cross-sectional area of aluminium conductor is required to carry a current with similar performance as a copper

1)

www.temcoindustrialpower.com/

12

Chapter 2. Background

conductor. Copper has higher tensile strength (TS), 220 MPa, and is used almost exclusively in all but the smaller size ranges, where an aluminium conductor may be acceptable

because of its low expense (approximately 25-40% in cost savings) and lightweight nature (low density, 2.70 g/cm3 ). Additionally, pure aluminium is not used as an electrical

conductor in equipment since it is too soft for mechanical assemblies and is thus alloyed

with other materials [37].

Utilization Factor The window utilization factor can determine the amount of a conductor that occupies the window area of the transformer, which is expressed by:

Ku = S1 S2 S3 S4

(2.15)

where

S1 —

S2 —

S3 —

S4 —

conductor area or copper area

the window area

the usable window area

the sum of the usable window area and insulation area

Theoretically, a coil wound by a round wire in square winding pattern has the square

magnet wire has less space between the wires when wound in a coil. The round wire

has the fill factor of 0.785 in square winding pattern, the fill factor of 0.907 in hexagonal

winding pattern, and the square wire has the fill factor of 1. Thus, the square wire has a

high lay fill factor and can be used in confined spaces.

2.4.2

Electrical Steel

For low frequency designs (50/60 Hz), where the losses produced by eddy current and

hysteresis effect are low, the materials used are usually silicon-steel laminations.

Introduction to Electrical Steel Electrical steel is a ferromagnetic material which has

enhanced soft magnetic properties (such as having a small hysteresis area, high permeability, low coercivity and high saturation magnetization) and is used for the magnetic

flux-carrying cores of electrical machines, transformers and generators, in which it is used

to amplify the magnetic flux. The characteristics of electrical steel have direct impact on

the performance and efficiency of above electromechanical devices.

When a transformer core is magnetised and then demagnetised due to an alternating

magnetic filed, it absorbs energy and causes hysteresis loss and eddy current loss. Electrical steel is an alloy material that has a low power loss, which is achieved by adding

silicon (Si) to the molten steel (Fe). Si can increase the electrical resistivity of the steel

to decrease the induced eddy currents and narrow the hysteresis area [38]. However, the

electrical steel is still a good conductor that has a low electrical resistivity in the range of

12 − 50 × 10−8 Ω · m [38]. To minimize eddy current loss a transformer core is stacked

together by thin lamination sheets with the thickness of 0.1 – 1.0 mm and a thin electrical

insulation coating with approximately 1µm thick [39–41].

In a transformer core manufacturing, different cutting methods, such as laser cutting,

punching, wire electrical discharge machining (WEDM), water jet cutting, etc, also influence on the magnetic properties of steel material. Electrical steel cutting procedure is an

13

Chapter 2. Background

unavoidable step in a transformer core manufacturing, and more details are presented in

Chapter 7.

Texture of Electrical Steel Crystallographic texture is one of the most important parameters determining the magnetic properties of steel sheets, which divides electrical steel

into two groups, the grain oriented (GO) electrical steel and non-oriented (NO) electrical

steel.

The texture of NO electrical steel is a Cube texture. The Cube texture is its (001)

or (110) plane parallels to the sheet plane (i.e., the [100] direction normal to the sheet

plane) and has a uniform distribution of the [100] direction. Hence, NO electrical steels

have uniform magnetic properties in all directions with respect to the rolling direction

(RD) [42]. They are used in rotating machines where the direction of magnetic flux is

circular, such as motors, generators and alternators.

The texture of GO electrical steel is a Goss texture with (110)[001] orientation in

which cubic crystals are all arranged in the RD. Hence, a GO steel is very anisotropic

and has much better permeability properties in the RD than it has at 90 degree to RD

(i.e., transverse direction (TD)) [43]. GO steels are used in transformers, transducers and

magnetic amplifier cores. GO steels can be used also in small electrical machines, but it

is ensured during a core construction that the lamination sheets are stacked at random so

the permanence of the machine does not very in different directions [44].

Grade of Electrical Steel The grade of electrical steels is classified by many standards.

For example, as presented in European Standard EN 10106 2) , the grade of M800-50A

means that an electrical steel has a dissipation power of 8 W/kg at a peak flux density of

1.5 T and a frequency of 50 Hz. Figure 2.4 shows the details of M800-50A nomenclature.

M800-50A

Non-grain oriented

0.5 mm, hundred-fold nominal thickness

8 W/kg, hundred-fold maximum permitted loss of magnetization

Electrical steel strip

Figure 2.4: Nomenclature of M800-50A presented in European Standard EN 10106

Electrical steel manufacturers and researchers use a standardized method named Epstein frame experiment3) to characterize and investigate the magnetic properties and iron

loss of electrical steels over a range of frequency and induction level. The working principle of an Epstein frame is similar to an unload transformer. It has a primary winding,

a secondary winding and the specimen of electrical steel strips as the transformer core.

The iron loss is measured by using watt-meter method. An Epstein frame is applicable

to GO and NO electrical steel sheets for AC measurements up to 400 Hz and also for DC

measurements [45–47].

2)

European Standard EN 10106 specifies cold-rolled NO electrical steel strip and sheet in nominal thickness of 0.35 mm, 0.50 mm, 0.65 mm and 1.00 mm

3)

International Electrotechnical Commission, IEC 60404-2

14

Chapter 2. Background

2.5

Review of Rotary Transformer

A rotary power transformer is used to couple the electrical power between two units that

rotate in relation to each other. It has the particularity of an air-gap to enable the rotation

between the primary and the secondary. The principle of a rotary transformer and a conventional transformer has no difference, which is that both of them can transfer electrical

power between two galvanic isolation circuits by means of electromagnetic induction.

Thus, the rotary power transformer can be developed to replace slip-rings and brushes

to achieve that the power transfer can implement over a physical distance. Using rotary

power transformer is one application of CET system for loads located in rotor part. A contactless transformer has a large air-gap as compared to conventional transformer. So its

construction causes large leakage inductance, small magnetizing inductance and low coupling coefficient. Therefore, due to the small magnetizing inductance a large amount of

magnetizing current flows through the entire primary windings, and it lowers the overall

system efficiency. Additionally, the large air-gap causes a high probability of noncompliance with electromagnetic compatibility (EMC) and safety regulations.

Though a contactless power transformer has the low coupling coefficient and brings

unsafely matters on EMC, it can be used in some particular applications where conventional connection solutions such as cable, slip-rings and brushes that are either impractical or cause dangerous of friction, wear and intermittent contact. Thus, the rotary power

transformer that is used for powering the new DC motor with on-rotor drive system can

avoid the problems above, extremely improve its power efficiency and working life and

reduce maintenance cost of the entire system.

As shown in Figure 2.5, [48–52] present rotary transformers with different structures

for their particular researches. (a) flat plane type and (b) axial type are the most common

(a)

(b)

(c)

(d)

Axis

Mechanical holder

Shaft

Rotor core

Stator core

Winding

Figure 2.5: Cross-sectional view of rotary transformer constructions

and easy way to insert coils. Because the air-gap is completely free, and it can be very

small. It should be noted that both types have “two” air-gaps in the cross-section view, and

they can aggravate the high magnetic flux leakage. [51] presents (c), a core geometry with

single air-gap, which can achieve a high magnetic coupling. [52] presents (d) another kind

of core construction that employs double windings on stator side to improve the coupling

coefficient. Furthermore, because there are no any cores in the rotor, (c) and (d) can

extremely lower the rotor’s weight, but they also have an expensive cast on the assembly

of a three-phase rotary transformer. Comparing the four structures above, (a), (c) and (d)

cause a complex assembly for the three-phase transformer, while (b) can be considered in

15

Chapter 2. Background

this transformer design.

Aluminium

(magnetic shielding)

Secondary coil and

ferrite (rotary)

Primary coil and

ferrite (stationary)

Shaft

Figure 2.6: Single phase pulsating magnetic field-based system [54].

Considering the core manufacturing on rotary transformer design, [9, 51, 52, 54–57]

use many U-shaped cores to constitute a circular array (Figure 2.6). Because cores are

rectangular cuboid, they leave many unshielded sector areas between each of two cores.

Therefore, this topology cannot cover all parts of windings and causes much more fringing

and leakage flux. As presented in [52] , this core structure uses an extra high permeability

sheet around the primary and secondary for shielding to improve the magnetic coupling.

According to these studies above, this thesis work explores a new geometry in core design

to build a rotary transformer to have a completely shielded construction.

Most of contactless transformers are used to supply power [8–14] or transfer signals

[7,9] for a movable target located on a rotary shaft [7–10,13] or a linear track [11,12,14].

Only few examples illustrate how to power the rotor unit of a motor system.

[48–50] present an application of three-phase rotary transformer used for powering

the rotor unit of a brushless doubly fed induction machine. It shows that using a rotary

transformer for the doubly fed induction machine can substitute the many disadvantages

of brushes and slip-rings. However, it connects to a variable frequency drive (VFD) with

working frequencies higher than hundreds of Hz rather than directly connects to the electric grid and using the mains voltage frequency. Those three papers also show the magnetizing flux behaviour obtained via an FEM software and present the unavoidable common

problem of air-gap that can cause high a leakage/magnetizing reactance ratio.

[58, 59] present a design of an iron silicon axial rotary transformer for a wound rotor synchronous machine (WRSM) for an integrated starter generator (ISG). It adopts a

sequential quadratic programming algorithm (SQP) and a coupled multi-physic model of

a FEM program FLUX 2D to optimize a rotary transformer. It achieves that a coupled

multi-physic models associated with the SQP optimization algorithm demonstrate that the

rotary transformer is a good challenger for the gliding contacts system in WRSM. This

paper also reveals that the choice of magnetic material for such applications mainly relies on the thermal conductivity, losses properties and mechanical strength of the material

instead of the saturation flux density level.

16

Chapter 2. Background

2.6

Summary

First, the basic concept of the transformer was introduced as well as the different transformer types. Second, general losses of the transformer were presented briefly, including the theory and calculation formulae for determining winding losses and iron losses

in transformers. Third, transformer materials, winding conductors and electrical steels,

were introduced. Last, a short review of the design and utilization of rotary transformer

was presented. Those basic concepts can assist the three-phase rotary transformer design

that is presented in the next chapter.

17

Chapter 3

Three-phase Rotary Transformer

Design

Nowadays, designing and achieving a high-performance and low-cost transformer is still

a complex task. In electrical power transmission system, in order to minimize transmission losses many electrical grids deliver a high-voltage and low-current power over a long

distance, and transformers are key units that can change the voltage level for different

requirements of transmission systems and ultimate users. Reducing transformer losses

and improving transformer reliability and performance have many challenges in scientific

and engineering works. Olivares presents several challenges in a transformer design [60]:

(a) to prevent transformers from too-high temperatures, (b) to provide sufficient insulation and to design the transformers so that they will withstand voltage conditions that are

indicated on standards, (c) to manufacture transformers with low losses, (d) to produce

transformer designs that can be manufactured, (e) to maximize transformer sales and to

minimize transformer total owning cost, (f) to minimize transformer weight, (g) to minimize noise, etc. Because of energy shortage and environmental concerns Olivares also

points out that (c) is a critical problem, and it is necessity to improve the efficiency of

transformers [61].

Until 2009, the major source of electricity generation is still the fossil fuel and has

67% of the total source in the world [62]. The fossil fuel includes coil, peat, oil and

natural gas, which cause emissions of carbon dioxide during the electricity generation.

Low-efficiency transformers influence the environment because they require more power

to support their work, which causes more emissions of carbon dioxide, and furthermore,

these low-efficiency transformers also contribute to the greenhouse effect [63]. Contrary,

a high-efficient transformer can reduce the energy consumed by itself and deliver more

power for further purposes, which can optimize the electricity usage and reduce the environmental impact of electricity generation.

Hence, first of all, understanding the loss components of the rotary transformer is an

essential requirement for achieving a high-efficient transformer in this design. Second,

the high-efficient transformer will extremely improve the performance of the permanent

magnet DC motor with on-rotor drive system. This chapter presents the structure of the

three-phase rotary transformer and then analysis its power loss in more detail. Furthermore, this chapter also presents available materials used in the transformer and proposes

an achievable core construction to use the transformer materials effectively.

18

Chapter 3. Three-phase Rotary Transformer Design

3.1

Three-phase Rotary Transformer Structure

d) Three-phase electric grid

a) Permanent magnet DC motor

with on-rotor drive system

e) AC/DC

g) Motor drive unit

f) Terminal box

h) Fan

b) Three-phase

rotary transformer

c)Single-phase

in 3D view

Figure 3.1: Three-phase rotary transformer structure

Figure 3.1 illustrates the construction of the permanent magnet DC motor with onrotor drive system and the three-phase rotary transformer. More details are described as

follows.

1. Because of the working principle of (a) the DC motor all electrical power consumption units (i.g., motor drive unit) of the motor are in the rotor side. The motor

eliminates the usage of conventional brushes or slips ring, which requires a transformer to transfer power over a physical distance. Hence, in this rotating machine,

the air gap is unwanted but unavoidable due to the necessity of physical movement

required between the stator and the rotor.

2. (c) a single-phase transformer is viewed by three-dimensional form to example and

present the structure of (b) the three-phase rotary transformer.

3. (f) Terminal box is the electrical connection interface between (d) the three-phase

electric grid and (b) the rotary transformer.

4. (b) The rotary transformer with (e) the AC/DC unit achieves a wireless power transmission and converts the power from (d) the three-phase electric grid to a lowvoltage and high-current DC power for (g) the motor drive unit.

5. (h) An external fan is added to blow outside air over the frame of the entire system

to lower the transformer temperature.

This transformer can be categorized by:

• Distribution and step-down transformer: This transformer is used for low voltage application and decreases the input voltage of 230 V to a low voltage for every

power phase to achieve a low-voltage and high-current transformer.

• Three-phase transformer: Three-phase power system is widely used in industrial

applications. The motor must have a standard power interface and use a three-phase

transformer for its usability of industrial environments.

19

Chapter 3. Three-phase Rotary Transformer Design

• Rotary Transformer: To avoid the fraction and wear caused by slip rings or

brushes, the rotary transformer can perform a non-contact operation to a transfer

three-phase utility power to the rotor side.

• Dry-type Transformer: The transformer has the power rating of 1.5 kVA with the

efficiency of over 90%, and a few parts of the power is dissipated as heat. Thus, the

dry-type cooling method can limit the temperature to a permissible range and ensure

the long life and stable operation of the transformer and the DC motor. Hence, the

entire machine is similar to a totally enclosed fan cooled (TEFC) motor.

3.2

Air-gap

The air-gap needed to separate the rotor from the stator should be as small as possible

to minimize the magnetizing power loss, but a large air-gap, which can have an enough

space, allows bigger manufacturing tolerances on their dimensions and the rotary movement resulting from mechanical deflection and looseness in their supporting bearings.

Practical, the smallest air gap for industrial machines is around 0.2 mm. Considering the

tolerances of the transformer manufacturing and assembly, this rotary transformer uses an

air-gap with the thickness of 0.3 mm.

The permeability of a transformer core is related to copper loss through magnetizing current, which is reciprocally proportional to the square of permeability [64]. The

approximation of copper loss is expressed by:

Pcu = a(µ0 )−2 + b

(3.1)

where a and b are constants in [65], and µ0 is called apparent permeability that is the

permeability of the transformer core with an air-gap and is expressed by Equation 3.2.

µ0 =

µcore

air

lmag + µcore ( lδmag

)

(3.2)

where µcore is the core material permeability, lmag the total magnetic path length, and δair

the air-gap length.

The permeability of the core is not utilized fully since there is an air-gap in the magnetic path of the rotary transformer core. As expressed in Equation 3.2, the apparent

permeability (µ0 ) increases with increase of the permeability of the core itself (µcore ).

However, due to the air-gap has a low permeability, the µ0 hardly changes when µcore

changes in a high range, but it can change remarkably if µcore changes in a low range.

Because the low µcore range corresponds to the higher induction range, electrical steel

sheets that have a high permeability at a high induction is required to reduce the copper

loss due to the exciting current. In summary, an electrical steel sheet with a high magnetic

permeability can improve the average permeability of transformer core and decreases the

copper loss. Therefore, both low iron loss and high magnetic permeability are important

for electrical steel sheets used in the high efficiency rotary transformer.

20

Chapter 3. Three-phase Rotary Transformer Design

3.3

Configuration of Transformer Connection

This rotary transformer, due to the three-phase, is configured as a Delta-wye (∆-y) connection. A ∆-y connected transformer has the following advantages for the design and

application of the three-phase rotary transformer.

• The primary windings due to ∆ connection can deliver the same power in a higher

voltage and a lower current, which enables the copper conductors to have less crosssection area than that of conductors used in Y connection. Therefore a ∆ connected

primary can minimize the stator volume.

• A load connected phase-to-neutral or a phase-to-ground fault produces two equal

and opposite currents in two phases in the primary circuit without any neutral

ground current in the primary circuit [66].

• The neutral of the Y grounded is referred to as a grounding bank, because it provides

a local source of ground current at the secondary side that is completely isolated

from the primary circuit. Therefore, phase-to-ground faults or current unbalance

in the secondary circuit will not affect ground protective relaying applied to the

primary circuit [66].

• The ∆-y connection provides harmonic suppression [66]. The magnetizing currents

have significant quantities of odd-harmonic components for the induced voltages

to be sinusoidal. In a ∆-y connection, the third harmonic currents, being equal in

amplitude and in phase with each other, are able to circulate around the path formed

by the ∆-connected windings. However, in a Y-y transformer connection, the only

path for the third harmonic current is through the neutral.

3.4

Power loss Analysis

The three-phase rotary transformer is a part and parcel of the permanent magnet DC

motor, which transfers utility power to the drive system located in the DC motor’s rotor.

The rotary transformer also contributes extra mechanical power losses (e.g., windage and

friction loss) to the DC motor during the rotation. Figure 3.2 outlines various losses in the

three-phase rotary transformer.

This thesis studies the rotary transformer as a static device and only investigates its

copper loss and iron loss. Other kinds of electrical losses are briefly introduced in this

section as well as the mechanical rotational losses.

• Electrical losses: They are caused by the power conversion between electrical and

magnetic energy in the rotary transformer.

– Winding loss and iron loss: The electrical operating principle of the rotary

transformer is same as that of a conventional transformer. Electrical current

flowing through the primary and secondary windings causes resistive heating

of the magnetic wires. The iron loss includes hysteresis loss and eddy current loss. They depend upon the magnetic properties of the material used for

building a transformer core. More details of both loss components have been

presented in Section 2.3.1 and 2.3.2.

21

Chapter 3. Three-phase Rotary Transformer Design

Winding loss

Hysteresis loss

Core loss

Eddy current loss

Electrical losses

Stray losses

Power loss of

three-phase

rotary transformer

Magnetostriction

Mechanical rotational losses

(rotor, shaft, bearing)

Frication loss

Windage loss

Figure 3.2: Summary of the power loss of the three-phase rotary transformer

– Stray loss: Stray loss is kind of power loss that remains after windings and

iron loss and is originate from the mechanical construction parts in a transformer [67–69]. Not all the magnetic field produced by the primary couple to

the secondary and some fluxes link with the mechanical structure and windings. These leakage fluxes may induce eddy currents within nearby conductive

mechanical parts, such as fasteners for machine assembly and the rotary shaft

in the rotor. Because the rotary shaft is an essential mechanical component in

the rotary transformer, the stray loss caused by it should be taken into account

for the transformer power loss study.

– Magnetostriction: Magnetostriction is a property of electrical steels that can

deform them during the magnetization [70]. In a transformer, because of alternating magnetization magnetostriction can vibrate the cores and windings

to produce audible noise and friction heating, thereby causing power losses.

• Mechanical losses: As in the complete permanent magnet DC motor, they are

caused by the power conversion between electrical and mechanical energy. When

the motor delivers the mechanical power to a load some mechanical losses occur in

the motor.

– Friction loss: The friction loss occurs in bearings and an air cooling fan of the

motor. This loss is attributed to the force that it takes to overcome the drag and

air resistance associated with rotating the rotor and cooling fan. The frictional

loss depends upon the rotor speed, the diameter of the shaft at the bearing and

coefficient of friction (COF) between the shaft and bearing [71].

– Windage loss: The windage loss is due to the turbulence of a medium among

the air-gap as the motor’s rotor and stator move past each other. In more

details, the windage loss is divided into three components: a) frication on the

disks of the rotor spider, b) frication on the cylindrical surface in the air-gap

and c) pumping of medium through unit [72].

22

Chapter 3. Three-phase Rotary Transformer Design

3.5

Core Construction and Material Selection

The main parameters for selecting a core for the transformer are material, shape, and

size. The frequency of the transformer to be operating is important for its material to be

determined. This is due to the materials indifference in resistivity, which in turn would

influence eddy current existence and behaviour.

Figure 3.3 shows the O-ring core structure of a single-phase. It is a shell type structure, which surrounds the winding completely. However, because of the fringing flux

phenomenon caused by the air-gap, this shell type core can not reduce the EMI prorogation effectively. To prevent excessive eddy current loss within the metal of the core itself

it must be laminated in a plane parallel to the flux path (More details are presented in Section 7.2). According to the flux direction respect to the rotary transformer axis, each core

of the single-phase transformer has an unique name shown in the cross-sectional view.

Primary/Stator

Rotor-radial core

Air-gap

Stator-radial core

Pri. winding

Sec. winding

Stator-axial core

Rotor-axial core

Flux direction

Flux direction

Rotor-radial core

Stator-radial core

Secondary/Rotor

Figure 3.3: Single-phase O-ring core structure. Left: axial view. Middle: cutaway view. Right: crosssectional view. In the cross-sectional view, the flux passes through all cores in the counterclockwise by

assuming the current flow of the primary winding is the out-of-plane direction. Hence, in all axial cores, the

flux direction is parallel to the axis of the rotary transformer and, as shown in the axial view, it is parallel to

the radial direction in all radial cores.

Figure 3.4 examples laminations that are cut from a roll of electrical strip. (a), the

radial lamination, in which the magnetic flux may flow in any direction, is similar to

a lamination used for producing an electric motor core. The axial core is produced by

winding a long sheet strip cut from the electrical steel in TD or RD (see (b) or (c) in the

figure). Due to the finite width of electrical steel, using many short discontinuous strips

cut in the TD to form the axial core may complex and expensive in a strip-wound core

manufacturing if the total length of all used axial laminations is bigger than the width of

electrical steel. Contrary, the strip slitted in RD can have a relative infinite length, which

is suitable for producing the axial core. It should be noted that, as illustrated in (b), the

flux direction in the axial lamination is perpendicular to the RD, which results that the

axial core does not use the electrical steel effectively, because the magnetic properties in

the RD are superior to those in other directions.

ThyssenKrupp PowerCore M235-35A is used for the rotary transformer core study,

and three reasons are presented as follows.

a) M235-35A is a NO electrical steel, in which the iron loss and magnetic properties

are practically similar in any direction of magnetization in the plane of the sheet.

b) As presented in the given data-sheets of ThyssenKrupp PowerCore NO and GO

electrical steels, although GO electrical steel has a lower iron loss than NO electrical steel, its low permeability limits the maximum magnetic flux density that can

23

Chapter 3. Three-phase Rotary Transformer Design

A roll of electrical steel strip

(a)

Flux direction (any deg. to RD)

Flux direction (0 deg. to RD)

Flux direction (90 deg. to RD)

(b)

Wmax = 1250 mm

Transverse direction (TD)

(c)

Rolling direction (RD)

Figure 3.4: Different flux directions of laminations cut from a roll of electrical steel strip. (a) radial

lamination, (b) axial lamination parallel to RD and (c) axial lamination parallel to TD.

be achieved in a transformer core. Section 3.2 presents that the air-gap lowers the

transformer core permeability. However, using the NO electrical steel, due to its

high permeability, can weaken the effects of air-gap as much as possible. By applying the same external H, using NO electrical steel can induce a higher magnetic flux

density in the transformer core than using a GO electrical steel, thereby increasing

the rotary transformer performance.

c) The electrical steel of M235-35A has the lowest inherent iron loss with 2.35 W/kg at

50 Hz and 1.5 T and the thinnest thickness with 0.35 mm in the series of PowerCore

NO electrical steel. Thus, using the M235-35A can minimize the core loss and eddy

current loss of the rotary transformer.

3.6

Summary

In this chapter, the structure and transformer category of the three-phase rotary transformer structure were introduced as well as the transformer winding connection. Then,

according to the structure, the power losses were presented in more detail. Last, an achievable core structure and core material selection were presented.

This thesis studies the rotary transformer as a static electrical device, focusing on the

electrical loss study. However, compared with the copper loss, the iron loss is the most

complicated loss to predict in transformers. Therefore, it is discussed in more detail in the

next chapters.

24

Chapter 4

Iron Loss Model Development for

Three-phase Rotary Transformer

4.1

Iron Loss Model

To predict the iron losses during the design or optimization process of electric machines,

engineers can choose from a wide range of models. [73] presents an overview of iron loss