LMX2581 Wideband Frequency Synthesizer with Integrated VCO

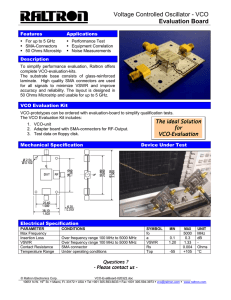

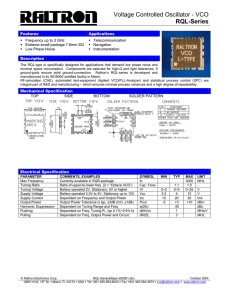

advertisement