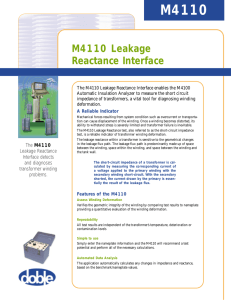

Leakage Reactance Interface

advertisement

M4110 Leakage Reactance Interface Detect transformer winding distortion easily with the M4110 Leakage Reactance Interface Patented* Test Method to detect Transformer Winding Distortion. Easy Comparison of Baseline Data to Future Test Data. Measurement Comparable to Factory Nameplate Data Good Repeatability of Test Results Simple to Use The leakage reactance measurement is a test that is easy to perform and serves as a reliable indicator of transformer winding distortion. Winding distortion, caused by the mechanical forces of an overcurrent event, can lead to immediate failure. Although a transformer can remain in service with partially deformed windings, its reliability is reduced. Winding distortion is not readily picked up by other AC field tests and should therefore be included during maintenance testing. The test is also recommended during acceptance testing, to uncover damage incurred during shipment. If one winding in a transformer is short-circuited, and test voltage is applied to another winding, the magnetic flux path includes the space between and within the windings. Reactance measured under these conditions is determined by the reluctance of that space, and is referred to as leakage reactance. Leakage reactance is sensitive to winding distortion and insensitive to temperature or presence of contamination. The M4100 instrument, together with the M4110 Leakage Reactance Interface, performs the leakage reactance measurement on transformers of any size and various winding configurations. The three-phase Leakage Reactance measurement can be compared to the short-circuit impedance nameplate value obtained at the factory. Individual phases can also be tested. The M4110 Leakage Reactance Interface contains the circuitry necessary to convert the voltage and current measured during a Leakage Reactance test on a transformer into a form that can be measured by the M4100 Instrument. It also contains a variac to obtain the proper test voltage. When using this interface, the standard M4000 safety switch and safety strobe are used. The required current and voltage cables are provided for connection to the transformer, along with the necessary software. *U.S. Patent 5,818,245. Australian Patent AU-52 105/93. European Patent Pending Doble Engineering Company 85 Walnut St. Watertown, MA USA 02472-4037 Tel +1 617.926.4900 Fax +1 617.926.0528 M4100 Instrument and M4110 Leakage Reactance Interface Test Connections Safety Switch Safety Strobe M4100 Low Voltage Lead M4100 Low Voltage Lead M4110 Voltage Source M4110 Voltage sense leads Black White Short-circuiting jumper should be rated for the current it will carry during the test. M4110 Specifications Impedance Measurement: Inductance: Range: 0.1 to 700 ohms Inductance Range Accuracy (@ 60 Hz at less than 10% Power Factor) Resistance: 250 µH to 1.8 H 1% of reading or ± 10 µH Resistance Range Accuracy (greater than 90% Power Factor) 0.1 to 700 ohms AC Input Requirements: Source Output Capability: 1% of reading or ± 10 milliohms 120 or 240 V at 10 A (50/60 Hz) 240 V rms Input 0-280 V rms Output Voltage 2.6 kVA Output VA Continuous Accuracy N.A. 120 V rms Input Short time overload current (120/240 V input) 0-280 V rms Output Voltage 25 A rms 4-8 minutes before thermostat shuts output off 1.2 kVA Output VA Continous Physical: Dimensions Weight 12”H x 10”D x 13.5”W 35 lbs. (31 cm H x 25 cm D x 34 cm W) 15.9 kG For more information, contact: Doble Engineering Company MRKT-SL-80 rev B 85 Walnut Street Watertown, MA 02472-9107 USA T. 617.926.4900 F. 617.926.0528 www.doble.com