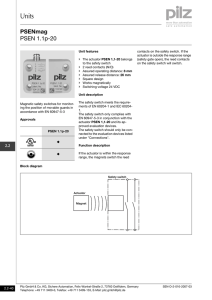

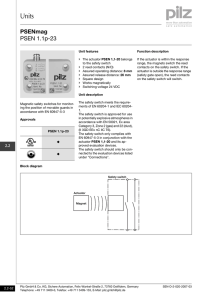

Sensor technology PSEN

advertisement