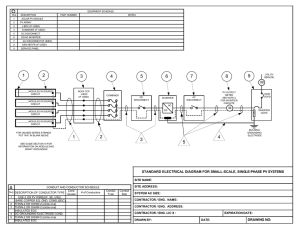

Expedited Permit Process for PV Systems

advertisement