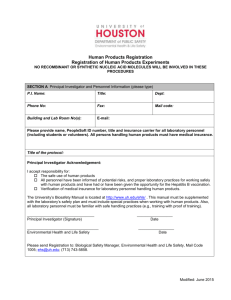

The management, design and operation of microbiological

advertisement